When your seed is in the ground – and even before – you need the tools to protect its potential. Crop protection products from Corteva Agrisicence™ give you the power to fight weeds, diseases, insects and nematodes while keeping nitrogen in the root zone. Find the right crop protection technology to maximize your acres.

Crop Protection

Crop Protection Solutions

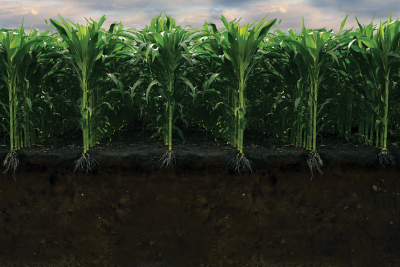

Corn Herbicides

Get power over weeds. These corn herbicides fit the way farmers grow corn, offering dependability and application flexibility.

See the power

Soybean Herbicides

Take control of your fields. Our soybean herbicides ease farmers' weed anxieties, help them better steward the land and improve their operation.

Get control

Cereals Herbicides

Overcome weed challenges. Our cereals herbicides offer flexible, convenient and customizable control to defeat any invading weed species.

Discover solutions

Rice Herbicides

Get rice weed control your way with herbicides compatible with all rice technologies and production systems.

Find your fit

Nitrogen Stabilizers

Get the max from your nitrogen. Our nitrogen stabilizers deliver unrivaled technology to help you protect any nitrogen source.

Learn how they work

Biological Crop Solutions

Keep your farm productive and healthy today and tomorrow with products designed to help you tackle challenges while enhancing profitability.

Embrace balance

Citrus Crop Protection

Manage your pest challenges and grow a healthier citrus crop with products designed to deliver excellent performance.

See proven protection

Peanut Crop Protection

Grow a healthier peanut crop and root out pests with high-performing herbicides, insecticides, fungicides and nematicides.

Protect your peanuts

OMRI Listed® Products

Get products approved for organic farming by the Organic Materials Review Institute.

Learn More

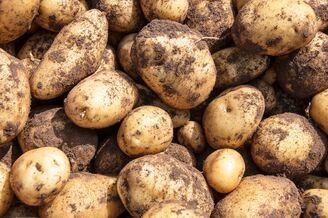

Potato Crop Protection

Protect your potato crop from pests with the latest in fungicides, insecticides and herbicides.

Protect your potatoesCrops We Serve

Different crops have different demands. Whatever you cultivate, we support your success with the seed, crop protection and digital farming technology to meet the changing needs of your crop and your operation.

How We Grow Progress

Our innovations are focused on the future of agriculture, to make a difference for growers today and in the years to come.

Aproach Prima®, Enlist One® herbicide, Enlist Duo® herbicide, Utrisha® P, Instinct NXTGEN®, Resicore®, Rezuvant™, and Transform® WG are not registered for sale or use in all states. Resicore is not available for sale, distribution or use in Nassau and Suffolk counties in the state of New York. Contact your state pesticide regulatory agency to determine if a product is registered for sale or use in your state. Consult the label before purchase or use for full details. Enlist One and Enlist Duo herbicides are the only 2,4-D products authorized for use in Enlist crops. Always read and follow label directions.