Our Personal Protection Promise

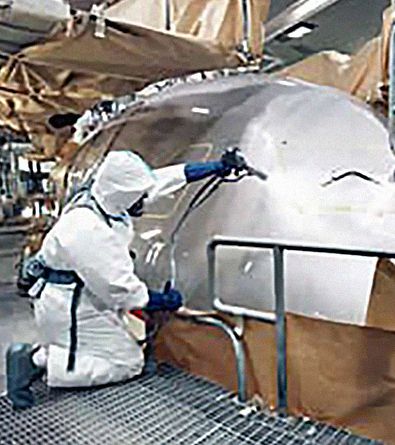

General manufacturing protection

Industrial protection—worker safety is our business

Industrial workers may have a variety of responsibilities while they’re on the job. We only have one — helping to safeguard people against hazards with industrial protection solutions from DuPont.

To be successful, industries depend on their workers. Behind these workers are families and communities who depend on DuPont Personal Protection to help keep their loved ones safe. For over 40 years, our scientists, engineers, and technicians have addressed the world’s safety needs with the best in safety technologies and innovations. We apply real-world experience as owners and operators of industrial manufacturing facilities around the world — offering our own workers the same science-based solutions that we offer yours, including some of the most trusted and innovative brands in the industry, like DuPont™ Kevlar®, DuPont™ Nomex®, DuPont™ Tyvek®, and DuPont™ Tychem®.

DuPont is collaborating with companies around the world, from industrialized to developing nations, to help them implement and strengthen regulations for the protection of all workers. So whether you’re concerned about meeting revised industry standards or looking for newer, safer ways to provide your workers with enhanced protection, we’ll help you understand that responsibility.

Articles & Case Studies

WEBINAR: FR face coverings in the COVID-19 era

View our webinar on the topic of the latest face mask guidance, FR and mask standards to consider for the industrial workforce, mask selection criteria, and additional resources and FAQs.

Cut & mechanical protection

Only Kevlar® can protect against multiple hazards, while keeping workers comfortable. And DuPont can help guide you through the new standards, innovation possibilities and more.

Tyvek® protective apparel

Tyvek® helps offer an ideal balance of protection, durability and comfort to employees in industrial applications and contamination control environments, including manufacturing, pharmaceutical, automotive and utilities.

Nomex® for manufacturing & transportation

When it comes to FR protection, Nomex® continues to meet and exceed global standards for protection and performance—providing safety managers with peace of mind and electricians with the confidence to get the job done. That’s why so many industry-leading companies trust Nomex® to keep their electricians safe.

Arc flash protection

Nomex® fabric delivers lightweight, comfortable FR protective solutions that meet or exceed global standards in arc flash, heat and flame protection and performance.

Chemical/HAZMAT protection

For protection against chemical dangers, industrial workers rely on Tychem® garments.

Controlled environments & cleanroom protection

DuPont offers a full spectrum of cleanroom garments and accessories for greater safety, comfort, protection against contamination and more.