Kalrez® specialty sealing engineered for your mission-critical applications.

From aerospace and chemical processing to chip manufacturing and oil and gas/renewable energy applications, DuPont™ Kalrez® elastomers are engineered to provide more stability, more resistance, and more effective sealing.

While DuPont didn’t invent o-rings or specialty sealants, it has a 40-year track record of innovation and development, creating sealants that stand up to the most challenging operating environments.

Aside from its cleanliness and purity, Kalrez® polymer chains are engineered to be one of the most inert polymer structures available, standing up to more than 1,800 different chemicals while offering high-temperature stability.

Kalrez® perfluoroelastomer parts are manufactured to the highest quality standards. Every part has documented traceability, and these parts provide one of the longest, most predictable lifespans in industry.

The long-term, proven performance of Kalrez® parts can mean less frequent seal changes, repairs, and inspections, increasing process and equipment uptime for greater productivity and yield.

Industries

Industrial

Our industrial material solutions are backed with extensive capabilities and experience in product design, application development, analytical testing and manufacturing scale up.

Energy

To meet the challenges of the global energy industry, our Kalrez® products meet the most demanding conditions in the most severe environments.

Advantages

Chemical resistance

Available in a number of different compounds, Kalrez® parts are formulated to optimize properties giving the best possible performance in various chemicals and temperatures.

Heat resistance

DuPont heat resistant plastics offer cost-effective, application-optimized choices to replace metal, ceramics and other polymers in a range of uses.

Rapid gas decompression

Reduce potential for seal failure with Kalrez® O-rings which have been certified by two independent labs to meet rigorous requirements for resistance to rapid gas decompression.

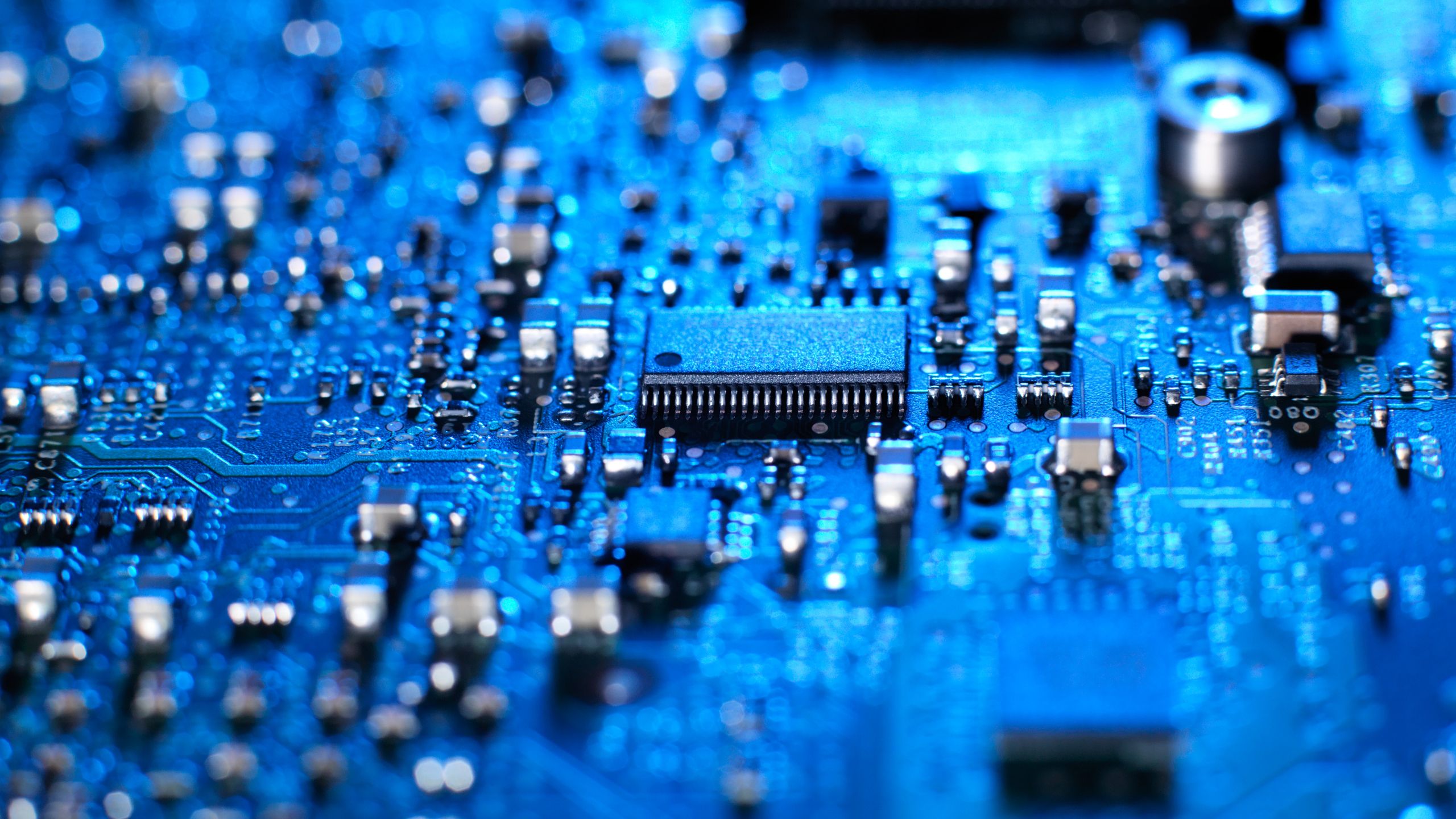

Minimize wafer contaminations

Purity is critical to wafer yield. Specially-formulated Kalrez® FFKM seals reduce wafer contamination from particles, outgassing and extractables.

Outgassing performance

DuPont™ Kalrez® bonded door seals are designed for easy installation and low particle generation.

Kalrez® sealing solutions for oil & gas

Kalrez® perfluoroelastomer parts provide best in class chemical resistance for exploration and production services while also meeting the industry standard requirements.

Solutions

Available in a number of different compounds, Kalrez® parts are formulated to optimize properties giving the best possible performance in various chemicals and temperatures.

DuPont heat resistant plastics offer cost-effective, application-optimized choices to replace metal, ceramics and other polymers in a range of uses.

Reduce potential for seal failure with Kalrez® O-rings which have been certified by two independent labs to meet rigorous requirements for resistance to rapid gas decompression.

DuPont™ Kalrez® bonded door seals are designed for easy installation and low particle generation.

Purity is critical to wafer yield. Specially-formulated Kalrez® FFKM seals reduce wafer contamination from particles, outgassing and extractables.