Vespel®SP-21 Thrust Washers

Case Study

Jatco

Thinner, lighter Vespel® SP-21 thrust washers replace all-metal needle bearings in a new 7-speed AT for rear-drive vehicles

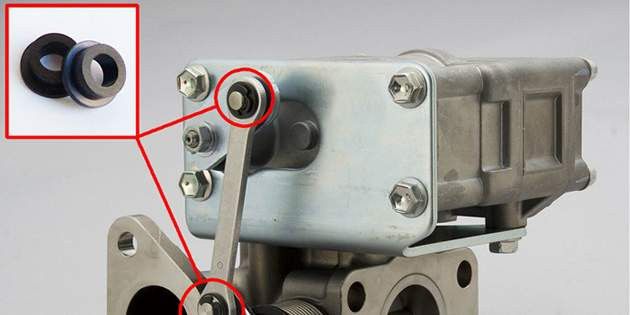

Vespel® thrust washers have been selected to replace larger and heavier metal thrust needle bearings positioned between the clutch casing and aluminum transmission housing.

The Challenge

Good mileage, compact design and fun to drive!

Occupying almost the same space as a 5-speed AT, JATCO Product new 7-speed transmission creates an exciting driving experience for luxury-class, rear-drive vehicles. The AT’s superior response time delivers both exciting acceleration and a quiet, leisurely experience depending on the driver's desire – while still improving fuel efficiency.

The Solution

Reduced size, weight and number of parts

Vespel® SP-21 thrust washers are thinner and lighter than comparable metal thrust needle bearings, helping to reduce the AT’s overall size and weight. In addition, Vespel® SP-21 thrust washers have been selected because they have the ability to rotate directly against the aluminum housing, allowing a reduction in the number of parts and an easier assembly process.

Key Advantages

Superior resistance to heat and wear. Capability of direct contact with aluminum components

Vespel® thrust washers have demonstrated many years of superb reliability in transmission applications due to:

- The lack of melting point means the washer will not melt

- A high limiting PV value (an indicator of resistance to wear) which is superior to other engineering resins

- Low-wear rates when used directly against lubricated aluminum components, even in the presence of contamination or foreign matter in the oil

- Custom-designed oil grooves on the washer surface allow precise control of oil flow, further enhancing resistance to wear

- The ability to easily form an oil film on its surface which creates a very low coefficient of friction

Ideas & innovations

Powered by a broad product portfolio and state-of-the-art expertise, we help our partners meet the critical industry demands of the electrical and electronics market.

Featured resources

Literature

Vespel® Parts for E-Mobility Applications

Vespel® Parts for Internal Combustion Engine Applications

Vespel® CR-6100 Compression Molded Parts and Shapes

Vespel® CR-6100 Bearings for API Separators

Vespel® CR-6100 Pipeline Pump Component Boost Efficiency

Vespel® Parts and Shapes in Electrical Vehicles - sell sheet

Case Studies

Vespel® CP-0664 Adds Life to V-Grooves

Vespel® ASB Channels Help Aircraft Thrust Reversers To Operate Longer And Safer

Vespel® Line Shaft Bearings for Pumps

Articles

Vespel® Powering Sustainable Mobility

Vespel® Boost Efficiency & Reduce Fuel Consumption

Vespel® Materials for Turbochargers

Additional links