Vespel® Case Rings Boost Pump Efficiency and Safety

Case Study

The Challenge

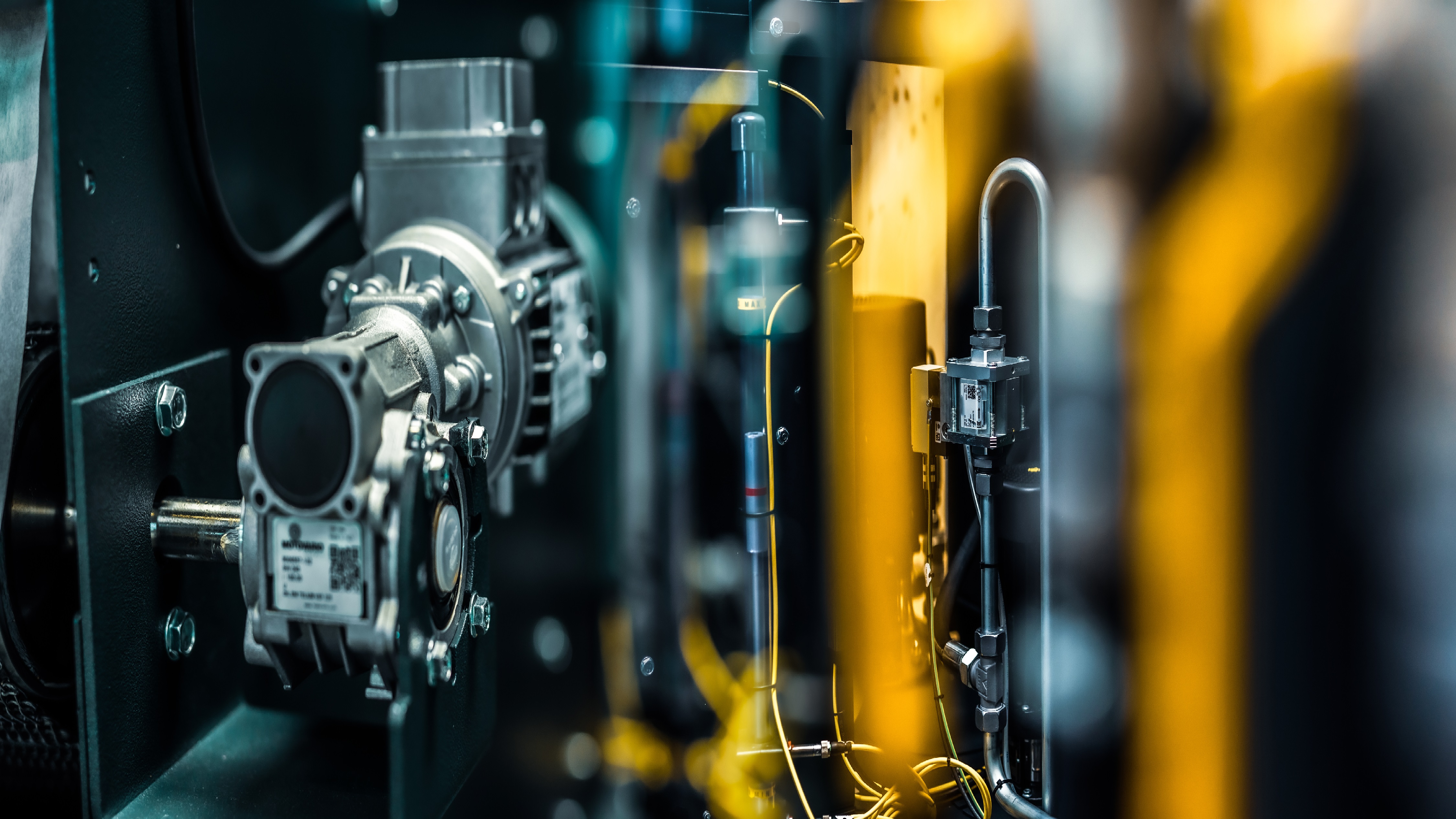

The operator of a pipeline in the Southwestern U.S. was searching for a case ring material for pumps that would enable improved operating efficiency, increase equipment reliability and avoid the seizing or galling problems encountered with metal components.

The pumps were nine-stage horizontally split units made by Sulzer Bingham. The process fluid consisted of natural gas liquids (NGL) at ambient temperature.

Tighter clearance. Reducing clearance between the case ring and the hard metal surface of the impeller is a proven method of increasing pump efficiency, but reducing the running clearances would increase the frequency of contact between the case ring and impeller, which increases the chance of galling or complete seizing.

Process upsets. Survival of case rings under run-dry conditions caused by process upsets is highly desirable.

The Solution

Vespel® CR-6100 parts.

The operator replaced metal components with Vespel® CR-6100 parts for nine case wear rings along with center, throat and throttle bushings in one of its pumps. Clearance between the case rings and impeller OD was just 0.010 inch (254 μm), about half the API-specified clearance for metal components in such pumps.

Key Advantages

- Higher efficiency. The operator measured a 3% gain in pump efficiency over the pump manufacturer’s performance test curve.

- Run-dry survival. Shortly after installation of the Vespel® CR-6100 parts, a control problem caused the pump to run "blocked-in" with both suction and discharge valves closed for 38 minutes. After the pump was shut down and cooled, operators were surprised that the rotor still turned freely. They then replaced mechanical seals, checked alignment, and returned the pump to normal operation.

- Increased safety. The operator reported that the continued operation of Vespel® CR-6100 parts during the process upset helped significantly in avoiding a release of hazardous material.

- Long life. The pump continued in operation for the next six months, completing its planned production cycle. During this time, there was no noticeable change in pump vibration or efficiency. At the end of the cycle, the pump was disassembled to inspect the rotor. The Vespel® CR-6100 parts had survived the incident with no measurable wear, and there was no damage to the pump rotor.

- Extending the benefits. Based on the proven 3% efficiency gain and run-dry capability of Vespel® CR-6100 parts in this particular situation, the operating company installed CR-6100 parts in the pipeline’s eight additional pumps.

Ideas & innovations

Powered by a broad product portfolio and state-of-the-art expertise, we help our partners meet the critical industry demands of the electrical and electronics market.

Featured resources

Literature

Vespel® CR-6100 Compression Molded Parts and Shapes

Vespel® CR-6100 Bearings for API Separators

Vespel® CR-6100 Pipeline Pump Component Boost Efficiency

Case Studies

Articles

Additional links