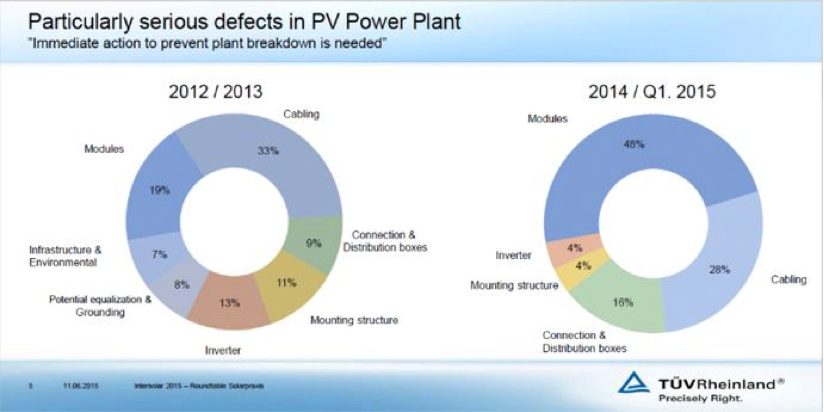

PV panel failures are not uncommon, with most of these defective modules using non field-proven materials. Even more, defects are seen among systems in use less than five years.

As early as 2010, DuPont tests revealed significant weaknesses in PET, polyamide, and PVDF-based backsheet materials, which are currently used in a large volume of solar panels in the field. Single-stress and sequential stress tests were conducted, revealing PV panel failures such as yellowing/embrittlement and cracking, caused by exposure to UV, extreme temperatures and humidity over time.

A Global, Growing Concern

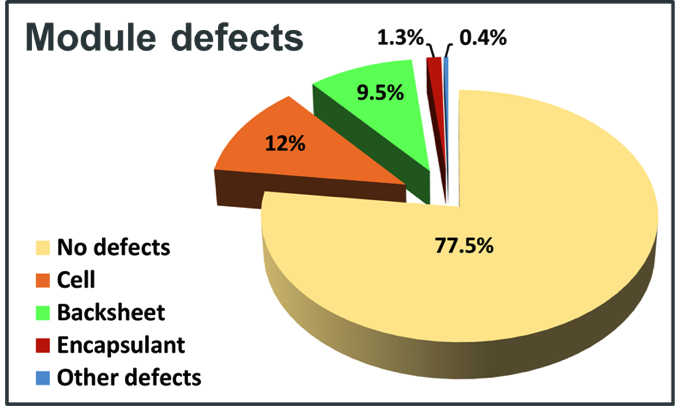

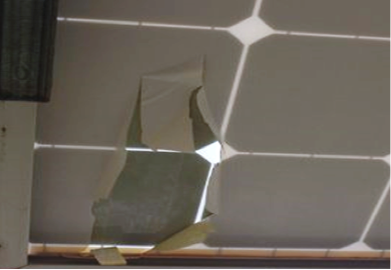

What was once thought to be isolated cases of failures is proving to be a more prevalent occurrence around the world, with many of those failures found in backsheets.

Globally, PV panel failures are growing.

- PA backsheets in the US, Europe, Asia, and Australia have shown cracking after just 3-5 years.

- Canada, the US, and China have experienced PVDF backsheet cracking and delamination in just 4 years.

- PET backsheets in the US, Spain, India, and China have shown yellowing / embrittlement, and delamination in just 4 years.

All of these cases have experienced backsheet failures at extremely young ages – an alarming statistic given the importance of performance and durability over the long haul.

The Root Cause

It can take years for new materials to fail in the field. However, immediately following installation, solar panels find themselves under extreme environmental, long-aging stresses, including:

Current Lab Testing Standards are Insufficient

Despite PET, PVDF, and PA-based backsheets passing IEC and solar panel manufacturer requirements, current testing standards are insufficient to ensure long-lasting durability and reliability of solar materials. They simply do not consider the importance of long-term performance of materials and what it means for the module maker, system owner, or other parties invested in solar.

The Solution

DuPont has a two-fold solution for how the industry can combat PV panel failures:

- Materials Matter – using field-proven materials that deliver long-term performance helps prevent PV panel failures, ensuring the lasting value of your system over the course of a lifetime.

- Adopt Module Accelerated Sequential Tests (MAST) – DuPont’s rigorous, proven testing protocol that more accurately measures the long-term performance characteristics of PV components by combining and repeating multiple aging stresses of of UV, heat, humidity and thermal cycling.

With 40+ years of PV experience, DuPont has developed and refined Sequential Test protocols that correlate to field performance and long-term reliability, ensuring your system and your solar investment continues to thrive, day after day.