Products

Our innovative product families are built on proven performance, and include the industry’s most effective specialty-separation and water-treatment products and technologies.

FilmTec™ portfolio

Learn about our globally recognized reverse osmosis (RO) and nanofiltration (NF) water-treatment solutions with an unsurpassed reputation for consistent, reliable, and long-lasting performance.

FilmTec™ Prime RO

The new FilmTec™ Prime RO brackish water elements boost performance to a prime level while reaching an unparalleled sustainability impact.

FilmTec™ Fortilife™ portfolio

Learn about our reverse osmosis (RO) and nanofiltration (NF) water-treatment product line for challenging waters, and how you can reduce costly waste, lower operating expenses, and move toward minimal liquid discharge.

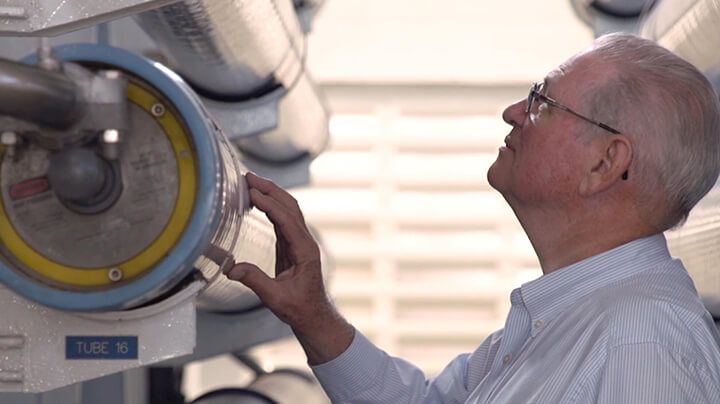

DuPont™ IntegraTec™ portfolio

Learn how pressurized, submerged, and integrated ultrafiltration module components can deliver the solution you need where you need it.

DuPont™ Amber Series

Learn about our broad and deep portfolio of ion exchange (IX) specialty-separation and water-treatment products for optimal plant productivity.

TapTec™ portfolio

Learn about our residential products designed for mainstream consumers who demand a higher quality of life with clean and safe household water.

MemPulse™ portfolio

Learn about our advanced MemPulse™ Membrane Bioreactor (MBR) technology and how it uses low pressure membranes to extract liquid from a suspended growth activated sludge system.

DesaliTec™ CCRO

Learn how DesaliTec™ closed circuit reverse osmosis (CCRO) systems can help provide consistent performance and ease of operation.

OxyMem™

Learn how our OxyMem™ portfolio is helping wastewater treatment plants reach their goals with 'drop-in' membrane aerated biofilm reactor modules.

Search all products

View our full list of specialty-separation and water-treatment products, including product data sheets.