Calculation of Scaling Risk

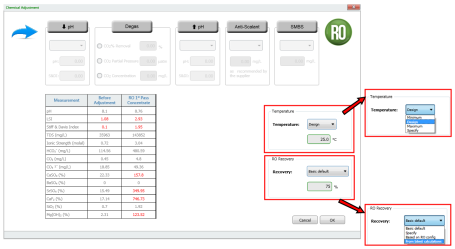

The Chemical Adjustment Popup Window in WAVE provides a convenient way to calculate the risk of scaling. Within the Chemical Adjustment Popup Window, the user can modify pH, temperature and Pass Recovery.

To calculate scaling risk at different Recovery values, one must follow these steps:

- Click on the dropdown arrow next to the Recovery field.

- Select the appropriate Recovery value:

- Basic default (75%),

- One based on the given RO/NF/ROSC configuration,

- One based on the previous WAVE run

- Another values (using the ‘Specify’) option.

-

The composition table would be updated automatically.

Figure 1: Scaling risk calculation using: Different recovery values

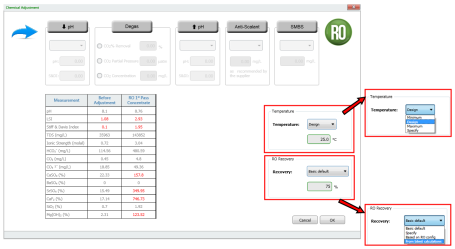

To calculate scaling risk at different temperature values, one must follow these steps:

- Click on the dropdown arrow next to the temperature field.

- Select the appropriate temperature value:

- Design temperature

- Maximum temperature

- Minimum temperature

- Another values (using the ‘Specify’) option.

-

The composition table would be updated automatically.

Figure 2: Scaling risk calculation using: Different recovery values and Different temperatures

Notes:

- Scaling risk in the Chemical Adjustment Popup Window is calculated in terms of the Langelier Saturation Index (LSI), Stiff & Davis Index (S&DI) as well as % saturation for some salts (CaSO4, BaSO4, SrSO4, CaF2), Mg(OH)2 and SiO2 .

- WAVE does not provide a mechanism to estimate the efficacy of antiscalants. Thus the user is advised to consult with an antiscalant manufacturer.

- Even though the user can estimate the scaling risk using different recovery and temperature values, neither the recovery nor the temperature values are transferred outside of the Chemical Adjustment Popup Window. If the user discovers a combination of temperature and recovery that would minimize scaling risk, he/she would have to copy over the values into the Home and Reverse Osmosis Tabs and perform the design again.