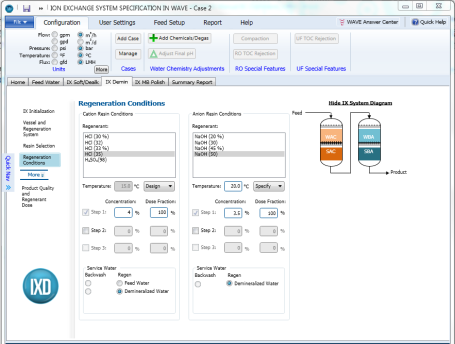

Defining the Regeneration Conditions

WAVE allows to specify some regeneration conditions in the Regeneration Condition Window, as shown in Figure 1. The following conditions can be specified for both cation and anion resins:

- Regenerant chemicals

- Regeneration temperature

- Number of regeneration steps, concentration and dose fraction

- Source of service water (Feed water, Treated water, Other water)

Select the required regenerants and specify the dosing temperature. It is also possible to dose the regenerant in a maximum of 3 different steps at three different concentrations, however the sum of all different dose fractions must be 100%. For the cation resin using sulfuric acid, WAVE will recommend regeneration conditions based on the feed water calcium to total cations ratio.

Finally, select the quality of service water for the backwash and the regeneration. The water quality selected for the regeneration is the water quality that will be used for injection and displacement rinse. For refill and fast rinse steps, feed water will be used.

Notes:

- In WAVE, the user must select a regenerant for cation/anion resins. The regenerant is selected from the list of default chemicals and other chemicals defined by the user (as described in Chemical Library).

- Based on the selected process, default values for regenerant concentration are recommended.

- When required (i.e., Brackish Softening with a WAC), WAVE will display the options for Step 1 (regeneration with acid) and Step 2 (resin conversion to Na form), as shown in Figure 2.

- WAVE allows 2 different options for the dosing temperature.

- Design: the dosing temperature will be the same as the one specified for the feed water in the Feed Water Tab

- Specify: when this option is selected, WAVE allows the user to specify the dosing temperature.

- WAVE will deactivate the water quality options for backwash according to the Regeneration System previously selected.

- In IX Condensate Polishing the only available source of service water is Other Water.

_455x343.png)

Figure 2: Regeneration Conditions for Brackish Softening with a WAC (H/Na)