Flow Diagram & Overview

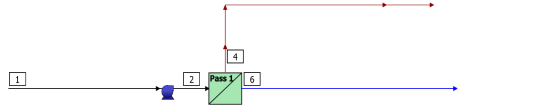

The following tables provide an overview of the system, the key difference with the CCRO output is that the Feed Pressure is provided over the range of CC Cycles, accounting for the increasing osmotic pressure. The report starts with a Process Flow diagram as shown below (Figure 1). The streams are numbered for clarity. As CCRO technology is a semi-batch process, flows vary between PF and CC Mode. The flow rates referred to by the process flow diagram and accompanying table are average values.

|

# |

Description |

Flow |

TDS |

Pressure |

|---|---|---|---|---|

|

(gpm) |

(mg/L) |

(psi) |

||

|

1 |

Raw Feed to RO System |

111.1 |

822.9 |

0.0 |

|

2 |

Net Feed to Pass 1 |

111.1 |

822.9 |

211.8 |

|

4 |

Total Concentrate from Pass 1 |

11.1 |

8,106 |

202.4 |

|

6 |

Net Product from RO System |

100.0 |

8.01 |

0.0 |

|

RO System Overview |

|||||||

|---|---|---|---|---|---|---|---|

|

Total # of Trains |

1 |

Online = |

1 |

Standby = |

0 |

RO Recovery |

90.0 % |

|

System Flow Rate |

(gpm) |

Net Feed = |

111.1 |

Net Product = |

100.0 |

|

|

|

Pass |

|

Pass 1 |

|---|---|---|

|

Stream Name |

|

Well Water - High Hardness |

|

Water Type |

|

Well Water (SDI < 3) |

|

|

|

|

|

Number of Elements |

|

25 |

|

Total Active Area |

(ft²) |

10000 |

|

Feed Flow per Pass |

(gpm) |

111.1 |

|

Feed TDSᵃ |

(mg/L) |

822.9 |

|

Feed Pressure |

(psi) |

182.1 - 211.8 |

|

Flow Factor Per Stage |

|

0.85 |

|

Permeate Flow per Pass |

(gpm) |

100.0 |

|

Pass Average flux |

(gfd) |

14.4 |

|

Permeate TDSᵃ |

(mg/L) |

8.01 |

|

Pass Recovery |

|

90.0 % |

|

Average NDP |

(psi) |

175.5 |

|

Specific Energy |

(kWh/kgal) |

1.88 |

|

Temperature |

(°C) |

16.7 |

|

pH |

|

7.8 |

|

Chemical Dose |

|

- |

|

|

|

|

|

RO System Recovery |

|

90.0 % |

|

Net RO System Recovery |

|

90.0% |