DuPont™ Styrofoam™ Brand Extruded Polystyrene (XPS) Foam Insulation low GWP update

Styrofoam™ Brand Polystyrene (XPS) Foam Insulation HFC compliance update

Our low GWP formulations feature a new grey color and the same great performance.

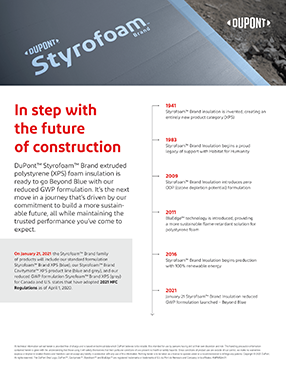

As states and provinces across North America continue the phase-down of HFC blowing agents in response to current environmental codes and regulations, DuPont is phasing in new, reduced global warming potential (GWP) formulations of Styrofoam™ Brand Extruded Polystyrene (XPS) Foam Insulation. Styrofoam™ Brand XPS products manufactured with the new formulations will be produced in a new, design friendly grey. The changeover is taking place first in Canada and select states, with plans to expand the product offering going forward.

While DuPont™ Styrofoam™ Brand XPS products are being reformulated with next-generation sustainable technology for an improved reduced embodied carbon profile, the performance characteristics and consistent quality of the original extruded polystyrene foam insulation will not change. Because of our industry leadership, we worked with regulatory bodies to best define the path to balancing performance and reliability with greater sustainability. We tested and refined all our products to be sure that Styrofoam™ Brand XPS will continue to meet or exceed codes and regulations and deliver the performance you've come to expect – in a color that meets modern design aesthetics.

DuPont™ Styrofoam™ Brand XPS Boardstock Blue to Grey Timetable

As of January 1, 2021, blue Styrofoam™ Brand XPS is transitioning to grey in Canada and select U.S. States. Throughout the transition period, both grey and blue colors will be available and compliant with current regulations where sold.

Get the latest HFC Update

Lisa Massaro

Advocacy & Product Stewardship Manager

DuPont Performance Building Solutions

Verified February, 2023

As of 1/1/2025 the US AIM Act will require Low GWP Styrofoam™ Brand XPS for newly manufactured product across the entire USA.

Published EPDs and Embodied Carbon

DuPont’s Styrofoam™ Brand Insulation GWP Phase-Down program offers lower embodied carbon product solutions compliant with specific US HFC and Canada GWP Regulations without compromising on performance.

Remember: Embodied carbon should only be reported by manufacturers using third-party verified EPDs, and comparison of EPDs should be interpreted with caution due to complexity in modeling product life cycles and the lack of quantified uncertainty in reported values. Many factors, including embodied carbon and other sustainability considerations, should be used to guide product decisions.

Published Environmental Product Declarations (EPDs) for selected XPS products available in regulated U.S. states

Published Environmental Product Declarations (EPDs) for selected XPS products available in regulated U.S. states

| Styrofoam™ Brand ST-100 |

Owens Corning Foamular® NGX™ |

Kingspan GreenGuard® LG |

|

|---|---|---|---|

| EPD Available? | Yes | Yes | Yes |

| Embodied carbon (A1-C4) kgCO2e/m2RSI |

6.2 | 9.8 | 4.5 |

| Embodied carbon (A1-C4) kgCO2e/bdft* |

0.5 | 0.8 | 0.4 |

| Leed Optimization Credit Eligible? | Yes, 2 (max possible+) | Yes, 1.5 (max possible) | No |

Published Environmental Product Declarations (EPDs) for selected XPS products available in Canada

Published Environmental Product Declarations (EPDs) for selected XPS products available in Canada

| Styrofoam™ Brand XPS | Owens Corning Foamular® NGX™ |

SOPREMA® Sopra-XPS |

|

|---|---|---|---|

| EPD Available? | Yes | Yes | Yes |

| Embodied carbon (A1-C4) kgCO2e/m2RSI |

6.2 | 9.8 | 2.1 |

| Embodied carbon (A1-C4) kgCO2e/bdft* |

0.5 | 0.8 | 0.2 |

| Leed Optimization Credit Eligible? | Yes, 2 (max possible+) | Yes, 1.5 (max possible) | No |

*To convert kgCO2e/m2RSI to kgCO2e/bdft, divide by 12.24. The 12.24 factor was calculated by the following equations:

1m2RSI = 1m2 * 1.14 inch = 1.02 ft3 (where 1m2 = 10.76 ft2 and 1.14 in = 0.095 ft)

1bdft = 1ft2*in = 1ft2*(1/12 ft) = 0.0833 ft3

1.02/0.0833 = 12.24 m2RSI / bdft

Code Approval Documentation

- Starting in 2021, newly formulated Styrofoam™ Brand ST-100 insulation foam produced for HFC regulated U.S. states is grey in color and approved for building applications as described in new ICC-ESR 4755

- All other Styrofoam™ Brand products, sold in non-HFC regulated states, are covered under ICC-ESR 2142, whether blue or grey formulations.

- Canadian Styrofoam™ products are listed under the same CCMC Listings as previous: CCMC 11420-L, 12085-L and 04888-L.

- Contact our single-entry point for Performance Building Solutions Technical Inquiries by calling 866-583-2583 or visiting our website for support for your state.

- Requirement: No person may manufacture or import any XPS product (Polystyrene—extruded boardstock, billet, and extruded sheet) in the US with a 100-yr GWP < 150 as of 1/1/2025

- Labeling: Requirements include the full date, or at minimum the four-digit year, of manufacture. The GWP of the blowing agent or the name of the blowing agent compound used must be noted on the product.

- Sell Through Period: Three years after the manufacture and import compliance date of 1/1/2025.

- Recordkeeping: Manufacturer must keep records and report annually.

- More Information: https://www.govinfo.gov/content/pkg/FR-2023-10-24/pdf/2023-22529.pdf?utm_campaign=subscription+mailing+list&utm_medium=email&utm_source=federalregister.gov

Buy America Act or Build America Buy America Act

- DuPont™ Styrofoam™ Brand foam insulation can be manufactured in the U.S. to qualify as a domestic construction material for use in projects subject to the Build America Buy America (BABA) Act, Pub. L. No 117-58, 70901-52, and/or a domestic component for use in projects subject to the U.S. Department of Transportation’s Buy America requirements, including 49 C.F.R. Part 661. For additional information, including certifications of compliance for specific covered projects, please contact us here.

- Labeling: Québec does not require labeling for foam products.

- Sell Through Period: Québec allows product manufactured or blended before the date of restriction to remain in commerce until July 1, 2021.

- Recordkeeping: Québec does not require recordkeeping for foam products.

- More Information: The original regulations are available here. The amending regulations are available here.

Regulations for all other Canadian Provinces

- Labeling: Canada does not require labeling.

- Sell Through Period: Canada allows product manufactured or blended before the date of restriction to remain in commerce.

- Recordkeeping: Canada does not require recordkeeping.

- More Information: The regulations are available in English here. The regulations are available in French here.

A unique closed-cell structure gives Styrofoam™ Brand XPS its exceptional moisture resistance and enables it to retain a high, long-term R-value of R-5 per inch – even after exposure to standing water, wet soil and other damp conditions. Additional performance attributes of Styrofoam™ Brand XPS include:

- Meets ASTM C578 Types (refer to specific product information for details)

- Compliant with IRC, IBC and IECC as listed in ICC Evaluated Service Reports

- Provides a weather-resistant barrier to enhance the building's resistance to air and moisture penetration

- Meets building code requirements of ASTM E84 Flame Spread Index of 25 or less and a Smoke Developed Rating of 450 or less

- Will not corrode, rot or support mold growth

- Available in wide range of compressive strengths from 15 to 100 psi, and minimum flexural strength of 40 psi

- Is easy to fabricate into various sizes, thicknesses and edge treatments to meet specific design needs, while ensuring energy efficiency and minimizing on-site cutting and waste

DuPont™ Styrofoam™ Brand XPS products are backed by the expertise of building science leaders dedicated to your success and warranties from a name you trust, including limited thermal warranties from 15 to 50 years including the Wall² system warranties and other system warranties.

Sustainability

DuPont™ Styrofoam™ Brand XPS Insulation has played a key role in the building and construction industry for nearly 80 years, enhancing energy efficiency and the sustainability profile of the entire building envelope. Thanks to the energy it saves over its lifetime, Styrofoam™ Brand XPS has been shown to help save more than 30 times the energy embodied in it. Based on published environmental product declarations, current Styrofoam™ Brand XPS will prevent at least 28 times more greenhouse gas emissions relative to its own carbon footprint over a 50-year period. Already manufactured with 100% renewable energy and a zero-ozone depletion formula, the sustainability benefits of Styrofoam™ Brand XPS include:

- Reusable in many applications

- Certified by UL Environment Inc. to contain an average of 20% pre-consumer recycled content

- Produced with BluEdge™ Polymeric Flame Retardant Technology, a stable polymer with an enhanced environment, health and safety profile

- Can help builders achieve green building certifications, including U.S. Green Building Council's Leadership in Energy and Environmental Design (LEED®) certification

Third party verified Environmental Product Declarations (EPD) through ULSpot® are available for Styrofoam™ Brand products:

- Styrofoam™ Brand ST-100 Series for U.S.

- Low GWP Grey Styrofoam™ Brand products (Canada)

- Traditional blue Styrofoam™ Brand products

Aesthetics

Grey, low GWP Styrofoam™ Brand XPS Insulation addresses the modern need for a dark reveal behind open-joint rainscreen systems or other applications where exposed insulation is desired. But that's not all. As a highly efficient continuous insulation, Styrofoam™ Brand XPS helps prevent thermal bridging which may lead to unsightly dark stains visible through cladding.

DuPont Performance Building Solutions is committed to being in step with where the construction industry is going. Our robust portfolio of proven and compatible products brings together decades of technology, expertise and innovation to provide water, air and thermal protection for all six sides of your building envelope.

When you're protecting all six sides of the building envelope, the Styrofoam™ Brand product family has long been the choice for solid performance.  Learn more

Learn more

1 R means resistance to heat flow. The higher the R-value, the greater the insulating power.

2 Styrofoam™ Brand Cavitymate™ Ultra Insulation, with patented carbon black technology, will continue to be produced in dark grey, delivering long-term insulating performance of R-5.6 per inch in wet cavity wall environments.

3 Not to be used in U.S. states with HFC regulations.

4 DuPont Styrofoam™ ST-100 EPD UL Declaration #: 4789868895.101.1.

5 Owens Corning NGX EPD Declaration # 4789639125.101.1

6 Kingspan Low GWP EPD referenced: Declaration #SCS-EPD-07176 (40 psi). Other Kingspan published EPDs: SCS-EPD-07175 (25 psi); SCS-EPD-07177 (60 psi)

7 Low GWP DuPont™ Styrofoam™ EPD UL Declaration #: 4789559274.102.1

8 Owens Corning Foamular® EPD Declaration # 4788721182.101.1

9 Calculated from life cycle analysis from published Styrofoam™ Brand Environmental Product Declaration Report.

10 Michael Mazor et al, "Life Cycle Greenhouse Gas Emissions Reduction From Rigid Thermal Insulation Use in Buildings", Journal of Industrial Ecology, 2011

The color PINK is a registered trademark of Owens Corning. THE PINK PANTHER™ & © 1964–2021 Metro-Goldwyn-Mayer Studios Inc. All Rights Reserved. The SOPREMA name, the SOPREMA logo, and all related names, logos, and product names are trademarks of SOPREMA or its affiliates or licensors.