High-performing materials to enhance PCB reliability for flexible and rigid boards

DuPont brings a deep understanding of materials science to the printed circuit board (PCB) market. We provide materials that support all aspects of PCB manufacturing for many types of PCBs: single- or double-sided boards and flexible, rigid-flex, or rigid configurations.

Tap into our long history as a market leader in flexible PCB laminates, dry film photoresists, and high-reliability metallization to determine the best combination of materials to enhance the performance of your PCBs. We allow you to push the design envelope and create products that perform faster and more reliably.

Our broad portfolio of PCB materials includes films, laminates, photoresists, and metallization. We continue to bring new products to market to create reliable PCBs with increased circuit density that function well under demanding environmental conditions.

Choose DuPont as your materials solutions partner to:

- Get a complete solution, not just materials

- Enable smaller and smarter PCBs

- Improve performance and enhance reliability

-

What are PCB Materials?

PCB manufacturing involves many steps—depositing metal and photoresist layers, imaging, etching, and stripping—all of which require materials tailored for a specific function. Whether they remain on the board or are removed during the manufacturing process, all PCB materials affect the performance and reliability of the final product.

-

Smaller, More Reliable Boards

The drive toward miniaturization in the consumer electronics and telecom sectors requires PCBs with higher circuit density, which puts greater demands on the metal and dielectric layers as line widths and spacings decrease. Choosing the right materials improves yield and controls manufacturing costs.

PCBs in automotive applications must operate reliably under conditions of high temperature and high voltage, where signal integrity is critical for safety. As the number of boards and components in vehicles increases, more function must be packed into a smaller space, elevating the importance of materials that enable compact, highly reliable designs.

Printed Circuit Board Materials

-

Metallization for Printed Circuit Boards

Metallization for Printed Circuit Boards

Reliable metallization for high-performing flexible and rigid PCBs.

DuPont’s longstanding expertise in electroless copper plating is an excellent match for the demands of flexible circuits built with polyimide.

Our highly conformal copper plating will enable any HDI design to perform well.

-

Laminates

Laminates

Laminate materials to enable the highest performing flexible and rigid-flex PCBs

Superior bond strength and flexibility for high volume applicationsDuPont adhesiveless all polyimide copper clad flexible laminates (CCL) are available in a wide variety of copper types, thicknesses and construction options.Our family of epoxy-based adhesive solutions offers superior peel strength, chemical, and heat resistance.DuPont’s family of fluoropolymer adhesive solutions delivers superior performance in high-speed and high frequency applications. -

Polyimide Films

Polyimide Films

From circuits in cameras in space to next-gen photovoltaic cells, polyimide films are helping make extraordinary new design possibilities actually happen.

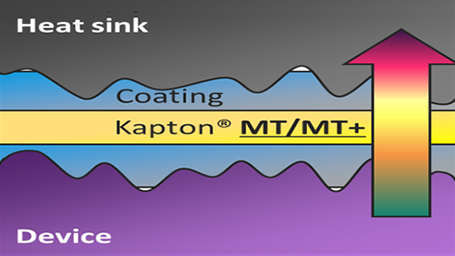

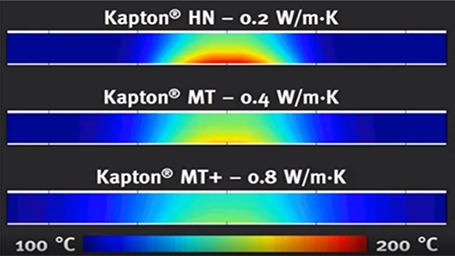

The Kapton® MT polyimide film family offers an enhanced thermal conductivity of 0.45W/mK compared to traditional Kapton® films. Additionally, the Kapton® FMT film product provides the added benefits of fluoropolymer, including improved chemical resistance and heat-sealing capabilities.Kapton® MT+ polyimide film family offers over 4x improved thermal conductivity with 0.8W/mK compared to traditional Kapton® films while maintaining superior mechanical, electrical, and thermal properties. Kapton® MT+ sets the industry standard for thermal conductivity performance in the polyimide category.Maintains its unique combination of mechanical properties under the harshest of conditions. -

Circuit Imaging Materials

Circuit Imaging Materials

Our portfolio of products is specifically engineered to enable PCB fabricators to easily achieve higher yields and greater productivity, even with today's most challenging designs.

The advanced solution for tall copper pillar process in advanced packaging application.The advanced fine line direct imaging photoresist solution for IC substrate application. -

Thermally Conductive PCB

We’re here to help.

We love to talk about how our electronics solutions can build business, commercialize products,

and solve the challenges of our time.