Nomex® Nano Flex: Tried and tested firefighter protection

The fire industry has shown a strong focus on creating innovative materials to better protect our first responders. DuPont™ Nomex® Nano Flex is no exception. It is thin, light, stretchable, and an excellent particulate barrier for protective apparel systems.

Nomex® Nano Flex is an elastic nonwoven made of submicron continuous and inherently flame-resistant fibers providing:

High degree of insulation from heat and low thermal conductivity

High filtration efficiency and particulate-blocking abilities

High breathability and comfort

Nomex® Nano Flex provides significant protection against smoke particles. In fact, tests show that hoods and composites* made with Nomex® Nano Flex offered 99 percent particulate-blocking efficiency, which is 4 times better than conventional hoods – even after 150 washes.

* 6.5 OSY Nomex® / 0.8 OSY Nomex® Nano Flex / 6.5 OSY Nomex®

Additional tests were performed on these hoods to answer outstanding concerns regarding the hood's durability over time and regular usage.

Test Results After 9 Months of Use

After 9 months of regular use for firefighting activities, hoods were retrieved and tested. The hoods remained intact, showing limited signs of wear and tear, meaning Nomex® Nano Flex sustains its capacity to block particles, even after 9 months of regular use!

Test Results After 250 Dons and Doffs

To further test the durability of the hoods, a test was performed at two local fire stations after 250 dons and doffs using hoods from three different manufacturers with different designs, including quilting and no-quilting. Each trial consisted of 250 cycles of donning and doffing, followed by one NFPA 1851 recommended washing and drying for 10 cycles. Despite these factors, the hoods maintained their protective performance.

Test Results on Smoke Residues After Wash

Case studies were conducted on hoods with Nomex® Nano Flex to address the following questions:

Case 1: Does washing remove particulates from the barrier layer of particulate-blocking hoods?

Case 2: Whether there may be the presence of certain dangerous chemicals in hoods with Nomex® Nano Flex under normal off-fire ground conditions after regular use and washing.

Case 1 – Visual Review Before and After Washing

Situation: A prototype hood with Nomex® Nano Flex was worn at a fire training academy for a 40-minute flashover training exercise then sent to DuPont™ for testing.

Results: Below shows the samples from the hood when viewed under 5x microscopy before and after washing.

Outer layer of hood as received

Outer layer of hood as received

Outer layer of hood after washing

Outer layer of hood after washing

Nomex® Nano Flex particulate protective layer as received

Nomex® Nano Flex particulate protective layer as received

Nomex® Nano Flex particulate protective layer after washing

Nomex® Nano Flex particulate protective layer after washing

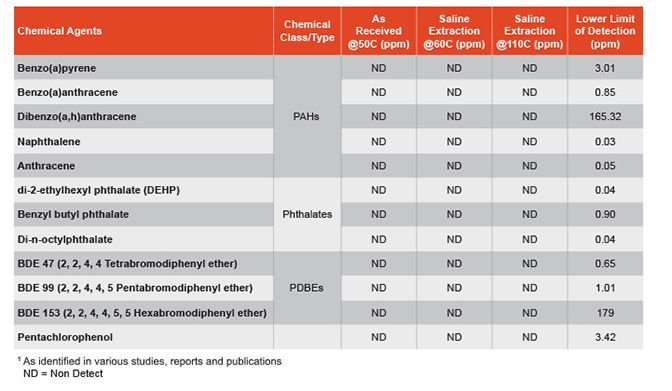

Case 2 – Analysis of Particulate Blocking Hoods for the Presence of 12 Chemicals

Situation: Three commercially available hoods with Nomex® Nano Flex were used and laundered by career firefighters for ~9 months then sent to DuPont™ for analysis.

Results: Samples from these hoods were analyzed for chemical agents to which firefighters are often exposed1; see below for the results.

Overall, this technology seeks to help reduce the firefighters’ exposure to particulates and allow as much moisture and air through to optimize comfort and minimize heat stress.

To purchase hoods made with Nomex® Nano Flex, please visit:

Disclaimer: DuPont is the manufacturer of Nomex® Nano Flex and does not design or manufacture firefighter hoods. This information corresponds to our current knowledge on the subject of firefighter hoods and may be subject to revision as new knowledge becomes available. It is your responsibility to investigate other sources of information on this issue that more appropriately addresses your product and its intended use.

The nature of fires may be very different. Therefore, it is very challenging to generate data that represents every possible chemical residue from firefighter PPE including particle barrier hoods. The types and levels of contaminants of a soiled hood can vary significantly. The conditions in these case studies may not be typical of the conditions encountered in your actual situations.

We are continuously looking for guidelines from NFPA project “How Clean is Clean” to identify what is needed to adequately clean personal protective equipment.

The user is solely responsible for any interpretations of the test data provided by DuPont and included in this material, and for all conclusions and implications made concerning the relationship between test data and real-life fire incidents. SINCE CONDITIONS OF USE ARE OUTSIDE OUR CONTROL, DUPONT MAKES NO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE AND ASSUMES NO LIABILITY IN CONNECTION WITH ANY USE OF THIS INFORMATION. This information is not intended for use by the user or others in advertising, promotion, publication or any other commercial use and is not a license to operate under, or intended to suggest infringement of, any existing trademarks or patents.