TD350S WB

DuPont™ Tyvek® 400 D

Effective January 2023, Tyvek® 400 D Pants are discontinued. Tyvek® 400 Pants available. DuPont™ Tyvek® 400 D Pants. Open Ankles. Elastic Waist. Serged Seams. Tyvek® 400 Front, ProShield® 10 Back

DUPONT™ SAFESPEC™ Terms of Use

Product Selector Agreement

The following information must be read and accepted by the user before proceeding.

The DuPont™ SafeSPEC™ Product Selector Tool (“Tool”) is intended to assist in choosing protective clothing styles for particular applications and does not replace the judgment of a qualified safety professional or industrial hygienist. Additional personal protective equipment (“PPE”), such as but not limited to: respiratory, eye, head, foot, and hand protection, may be required. Supplying the proper hazard/chemical and exposure information for your hazard scenario is critical in order to obtain suggestions of possible garment options for your consideration. Inaccurate information could result in improper suggestions. Since there are other factors involved which could affect the final PPE decision and may not be considered in this Tool, the final decision on protective clothing selection is the responsibility of the buyer, safety professional, industrial hygienist and end-user. DuPont de Nemours, Inc. or its affiliates DISCLAIM ANY RESPONSIBILITY OR LIABILITY FOR ANY INFORMATION OR SUGGESTIONS PROVIDED BY THE TOOL OR THE USE THEREOF.

WARNING / CAUTION

There are uses, environments and chemicals for which any garment will be unsuitable. It is the responsibility of the user to review available data and verify that the garment selected is appropriate for the intended use and meets all specified government and industry standards.

Search by :

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 1 of 3

You may enter from one to five chemicals or other hazards that may be present in your working environment. Our tool will find the best product match for the combined hazards. Enter a single chemical or hazard if you wish to find the best possible product match for that one hazard.

Chemical or Other Hazard Name

or

CAS Number

| Chemical Details | CAS | Actions |

|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 2 of 3

CHEMICAL COMPARISON

The table below shows the Normalized Breakthrough times of fabrics for the hazards selected. (Testing Details) You can find specific garments that protect against these hazards by clicking the 'Next' button below.

Done

Done

Done

|

|

|

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 3 of 3

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

step3of3

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

For a general fabric overview, please view our

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

For a general fabric overview, please view our

.jpg)

Technical Data Sheet

Related Products

DuPont™ ProShield® 70 Shoe Cover with ProShield® 70 Skid-Resistant Sole. Durable, gray shoe cover for industrial applications. 8.25" high, featuring an elastic opening at the top. Suitable for a wide variety of applications.

DuPont™ Tychem® 2000 Sleeve. Offers lightweight and durable protection against a variety of industrial chemical threats. Yellow, 18" long sleeve features elastic at both ends for arm protection. Suitable for light liquid splash protection in industries such as chemical processing, petroleum refining, pharmaceutical manufacturing, and food processing.

DuPont™ Tyvek® 400 Boot Cover with Tyvek® Sole. 18" High. Serged Seams. White.

DuPont™ Tyvek® 400 Shoe Cover with Tyvek® Sole. 5" High. Serged Seams. White.

DuPont™ Tyvek® 400 Shoe Cover with Tyvek® Sole. 8.25" High. Serged Seams. White.

DuPont™ Tyvek® 400 Sleeve. 18" Long. Elastic at Both Ends. Serged Seams. White.

DuPont™ Tyvek® 400 Hood. Elastic Around Face Opening. Shoulder Length. Serged Seams. White.

DuPont™ Tyvek® 400 Boot Cover with Tyvek® FC Skid-Resistant Sole. 18" High. Serged Seams. White.

DuPont™ Tyvek® 400 FC Shoe Cover with Tyvek® 400 FC Skid-Resistant Sole. 5" High. Serged Seams. Gray.

DuPont™ Tyvek® 400 FC Boot Cover with Tyvek® 400 FC Skid-Resistant Sole. 18" High. Serged Seams. Gray.

FEATURES & PRODUCT DETAILS

DuPont™ Tyvek® 400 D garments combine the protection, durability and comfort of DuPont™ Tyvek® fabric on the front and the comfort, softness and breathability of DuPont™ ProShield® 10 fabric on the back. The DuPont™ Tyvek® 400 D garments are suitable for applications where comfort requirements are combined with limited protective requirements for frontal exposures. Garments are available in a variety of styles. Applications include fiberglass and composite manufacturing, wind turbines, boat construction and repair, remediation, and maintenance.

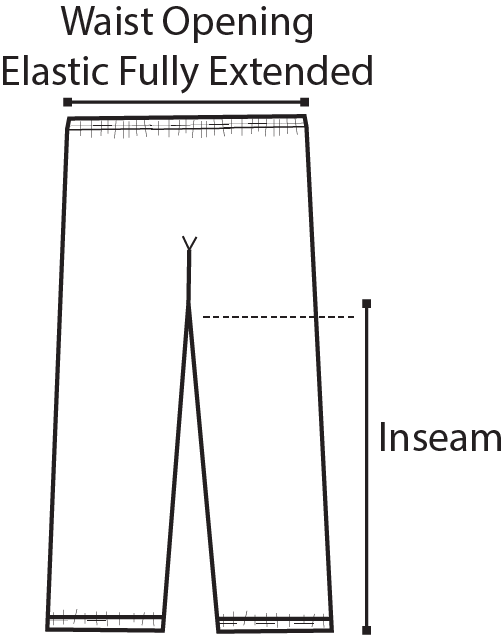

- Pants with open ankle and elastic at waist for easy donning and removal.

- Suitable for applications that do not require the full body coverage of a coverall.

- Manufactured under specifications that do not contain natural rubber latex

AVAILABLE OPTIONS

FINISHED DIMENSIONS

ADDITIONAL EQUIPMENT NEEDED

FABRIC & CHEMICAL RESISTANCE DATA

Physical Properties

Data relating to mechanical performance of the fabrics used in DuPont chemical protective clothing, listed for the selected garment according to the test methods and relevant European standard, if applicable. Such properties, including abrasion and flex-cracking resistance, tensile strength and puncture resistance can help in the assessment of protective performance.

| Property | Test Method | Typical Result |

|---|---|---|

| Thickness | Tyvek® - ASTM D1777 ProShield® 10 - ASTM D1117 |

5.9 mils 12 mils |

| Basis Weight | Tyvek® - ASTM D3776 ProShield® 10 - ASTM D3776 |

1.2 oz/yd2 1.3 oz/yd2 |

| Burst Strength - Mullen | Tyvek® - ASTM D774 ProShield® 10 - ASTM D3786 |

50 psi 23 psi |

| Tear Resistance - Trap Tear (MD) | Tyvek® - ASTM D5733 ProShield® 10 - ASTM D5733 |

6 lbf 4.5 lbf |

| Tear Resistance - Trap Tear (CD) | Tyvek® - ASTM D5733 ProShield® 10 - ASTM D5733 |

5 lbf 7 lbf |

| Breaking Strength - Grab (MD) | Tyvek® - ASTM D5034 ProShield® 10 - ASTM D5034 |

18 lbf 17 lbf |

| Breaking Strength - Grab (CD) | Tyvek® - ASTM D5034 ProShield® 10 - ASTM D5034 |

22 lbf 14 lbf |

| Hydrostatic Head | Tyvek® - AATCC 127 ProShield® 10 - AATCC 127 |

45" H2O 20" H2O |

| Surface Resistivity (23°C / 25% RH). | Tyvek® - EN 1149 ProShield® 10 - EN 1149 |

<2.5 x 10^9 ohms |

| Wearing Apparel Flammability | Tyvek® - 16 CFR 1610 ProShield® 10 - 16 CRF 1610 |

Class 1 Class 1 |