ST127S WH

DuPont™ Tyvek® 400 SFR

DuPont™ Tyvek® 400 SFR Hooded Coverall. Secondary flame resistance with the protection, durability, and comfort of Tyvek®. White coverall features a relaxed fit design, a standard fit hood, a storm flap, a red zipper, elastic wrists and ankles, and red external serged seams. For use over primary FR clothing. Suitable for oil & gas, manufacturing, maintenance, and utilities applications.

DUPONT™ SAFESPEC™ Terms of Use

Product Selector Agreement

The following information must be read and accepted by the user before proceeding.

The DuPont™ SafeSPEC™ Product Selector Tool (“Tool”) is intended to assist in choosing protective clothing styles for particular applications and does not replace the judgment of a qualified safety professional or industrial hygienist. Additional personal protective equipment (“PPE”), such as but not limited to: respiratory, eye, head, foot, and hand protection, may be required. Supplying the proper hazard/chemical and exposure information for your hazard scenario is critical in order to obtain suggestions of possible garment options for your consideration. Inaccurate information could result in improper suggestions. Since there are other factors involved which could affect the final PPE decision and may not be considered in this Tool, the final decision on protective clothing selection is the responsibility of the buyer, safety professional, industrial hygienist and end-user. DuPont de Nemours, Inc. or its affiliates DISCLAIM ANY RESPONSIBILITY OR LIABILITY FOR ANY INFORMATION OR SUGGESTIONS PROVIDED BY THE TOOL OR THE USE THEREOF.

WARNING / CAUTION

There are uses, environments and chemicals for which any garment will be unsuitable. It is the responsibility of the user to review available data and verify that the garment selected is appropriate for the intended use and meets all specified government and industry standards.

Search by :

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 1 of 3

You may enter from one to five chemicals or other hazards that may be present in your working environment. Our tool will find the best product match for the combined hazards. Enter a single chemical or hazard if you wish to find the best possible product match for that one hazard.

Chemical or Other Hazard Name

or

CAS Number

| Chemical Details | CAS | Actions |

|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 2 of 3

CHEMICAL COMPARISON

The table below shows the Normalized Breakthrough times of fabrics for the hazards selected. (Testing Details) You can find specific garments that protect against these hazards by clicking the 'Next' button below.

Done

Done

Done

|

|

|

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 3 of 3

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

step3of3

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

For a general fabric overview, please view our

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

For a general fabric overview, please view our

FEATURES & PRODUCT DETAILS

DuPont™ Tyvek® 400 SFR garments are lightweight, disposable secondary flame-resistant overgarments designed to help protect and preserve primary flame-resistant garments, while providing an ideal balance of protection, durability, and comfort.

In the event that a flash fire occurs, Tyvek® 400 SFR garments won't ignite and won't contribute to additional burn injury if appropriate primary flame-resistant personal protective equipment, such as DuPont™ Nomex®, is worn beneath.

Composed of flash spun high density polyethylene breathable nonwoven Tyvek® fabric that has been flame-retardant treated, available only from DuPont, Tyvek® 400 SFR garments offer an inherent barrier against particles (down to 1.0 micron in size).

Tyvek® 400 SFR represents a new generation of disposable secondary flame-resistant garment technology. Compared to traditional disposable secondary flame-resistant garments that have been available for years, Tyvek® 400 SFR is a differentiated multi-hazard garment solution, offering superior particle barrier protection and improved durability in a lighter-weight fabric. This unique combination of performance allows Tyvek® 400 SFR garments to be worn over primary flame-resistant garments like Nomex® when hazardous particle and flash fire hazards exist. Additionally, Tyvek® 400 SFR is a more sustainable garment solution and can be recycled through the Tyvek® protective apparel recycling program if not contaminated with hazardous materials.

Applications include: oil & gas, general manufacturing/operations, maintenance, dirty jobs, environmental services, utilities.

- Relaxed fit coverall design features a diamond gusset crotch to allow for unrestricted movement and optimal fit when wearing primary flame-resistant protective clothing beneath

- Red trim elements – red external stitched seams, red zipper, and red chest patch border

- Patent-pending design

- Attached standard-fit hood with elastic around face opening

- Elastic opening for tighter fit at wrist

- Elastic opening for tighter fit at ankle

- Storm flap

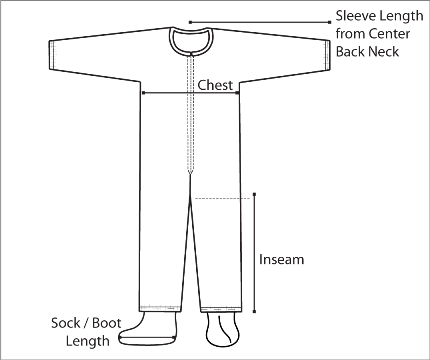

FINISHED DIMENSIONS

ADDITIONAL EQUIPMENT NEEDED

AVAILABLE OPTIONS

FABRIC & CHEMICAL RESISTANCE DATA

Physical Properties

Data relating to mechanical performance of the fabrics used in DuPont chemical protective clothing, listed for the selected garment according to the test methods and relevant European standard, if applicable. Such properties, including abrasion and flex-cracking resistance, tensile strength and puncture resistance can help in the assessment of protective performance.