TY178S HP

DuPont™ Tyvek® 500 HP

DuPont™ Tyvek® 500 HP (Harness Protection) Hooded Coverall with Four Attached D-Ring Sleeves. Designed to be worn over a full-body harness while protecting against fine particles and light liquid splash. White coverall features a patent pending ergonomic-protective design, multiple access points to the full-body harness (worn underneath the garment) through four elasticized D-Ring sleeves, an off-centered zipper entry to accommodate the front D-Ring sleeve, a 3-piece hood, elastic wrists, ankles, waist, and hood, thumb loops made of Tyvek® fabric, and a pin lock slider zipper pull. Suitable for a variety of applications, including cleaning, painting, and maintenance.

DUPONT™ SAFESPEC™ Terms of Use

Product Selector Agreement

The following information must be read and accepted by the user before proceeding.

The DuPont™ SafeSPEC™ Product Selector Tool (“Tool”) is intended to assist in choosing protective clothing styles for particular applications and does not replace the judgment of a qualified safety professional or industrial hygienist. Additional personal protective equipment (“PPE”), such as but not limited to: respiratory, eye, head, foot, and hand protection, may be required. Supplying the proper hazard/chemical and exposure information for your hazard scenario is critical in order to obtain suggestions of possible garment options for your consideration. Inaccurate information could result in improper suggestions. Since there are other factors involved which could affect the final PPE decision and may not be considered in this Tool, the final decision on protective clothing selection is the responsibility of the buyer, safety professional, industrial hygienist and end-user. DuPont de Nemours, Inc. or its affiliates DISCLAIM ANY RESPONSIBILITY OR LIABILITY FOR ANY INFORMATION OR SUGGESTIONS PROVIDED BY THE TOOL OR THE USE THEREOF.

WARNING / CAUTION

There are uses, environments and chemicals for which any garment will be unsuitable. It is the responsibility of the user to review available data and verify that the garment selected is appropriate for the intended use and meets all specified government and industry standards.

Search by :

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 1 of 3

You may enter from one to five chemicals or other hazards that may be present in your working environment. Our tool will find the best product match for the combined hazards. Enter a single chemical or hazard if you wish to find the best possible product match for that one hazard.

Chemical or Other Hazard Name

or

CAS Number

| Chemical Details | CAS | Actions |

|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 2 of 3

CHEMICAL COMPARISON

The table below shows the Normalized Breakthrough times of fabrics for the hazards selected. (Testing Details) You can find specific garments that protect against these hazards by clicking the 'Next' button below.

Done

Done

Done

|

|

|

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 3 of 3

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

step3of3

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

For a general fabric overview, please view our

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

For a general fabric overview, please view our

FEATURES & PRODUCT DETAILS

Workers operating with a full-body harness in environments where hazardous particle or light liquid aerosol hazards are present, previously had to compromise between efficient personal protection* and protecting their full-body harness against external contamination.The new Tyvek® 500 HP TY178S HP garment offers a unique solution – protection of both the wearer and the full-body harness – by providing a barrier between the user and the particle or light liquid aerosol hazards* in the environment. Designed to be worn over a full-body harness, the innovative, patent-pending garment design allows workers to access and utilize multiple D-Rings on their full-body harness while providing an ideal balance of protection, durability, and comfort. This new TY178S HP model has four attached sleeves for use with front, back and side D-Rings of a full-body harness. The off-centered zipper entry allows accommodating the front D-Ring sleeve for front D-Ring connection. *The user must ensure the garment is suitable for the chemical hazard before use. Please refer to chemical permeation data available in SafeSPEC™ to help you understand the level of protection the garment offers.

Compatible with a variety of full-body harness models, this garment may be used for a wide range of applications including painting, cleaning, maintenance, and more.- Innovative, patent-pending design for applications where full-body harness is worn; garment is designed to be worn over the full-body harness

- Multiple access points to the full-body harness through the four elasticized D-Ring sleeves that are attached to the garment – one in the front, one in the back, and one on each side of the garment

- Off-centered zipper entry to accommodate the front D-Ring sleeve for front D-Ring connection

- Certified according to Regulation (EU) 2016/425.

- Chemical protective clothing, Category III, Type 5-B and 6-B

- EN 14126 (barrier to infective agents), EN 1073-2 (protection against radioactive contamination)..

- Antistatic treatment (EN 1149-5) – on both sides of the fabric

- 3-piece hood with elastic face opening

- Stitched seams

- Tyvek® thumb loops

- Pin locking slider locks in place when the pins on the puller are pushed into the zipper elements

- Tyvek® storm flap

- Elasticated ankles & wrists and elasticated (glued-in) waist

- Ample crotch area

- Manufactured under specifications that do not contain silicone or silicone oils

- Dynamic Fall Test with an articulated mannequin – Tested in an independent testing laboratory as well as at a harness manufacturer with a conclusion that the Tyvek® 500 HP TY178S HP garment is not anticipated to affect the dynamic fall test performance of the full-body harness when worn underneath this garment. The test is successful as it demonstrated that the Tyvek® 500 HP TY178S HP garment is not impairing the proper function of the full-body harness in case of a fall.

ADDITIONAL EQUIPMENT NEEDED

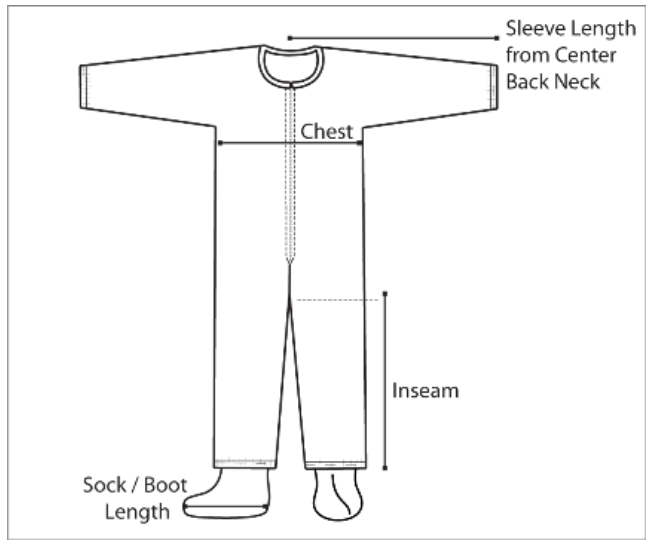

FINISHED DIMENSIONS

AVAILABLE OPTIONS

FABRIC & CHEMICAL RESISTANCE DATA

Physical Properties

Data relating to mechanical performance of the fabrics used in DuPont chemical protective clothing, listed for the selected garment according to the test methods and relevant European standard, if applicable. Such properties, including abrasion and flex-cracking resistance, tensile strength and puncture resistance can help in the assessment of protective performance.