News & Events

Electronics News

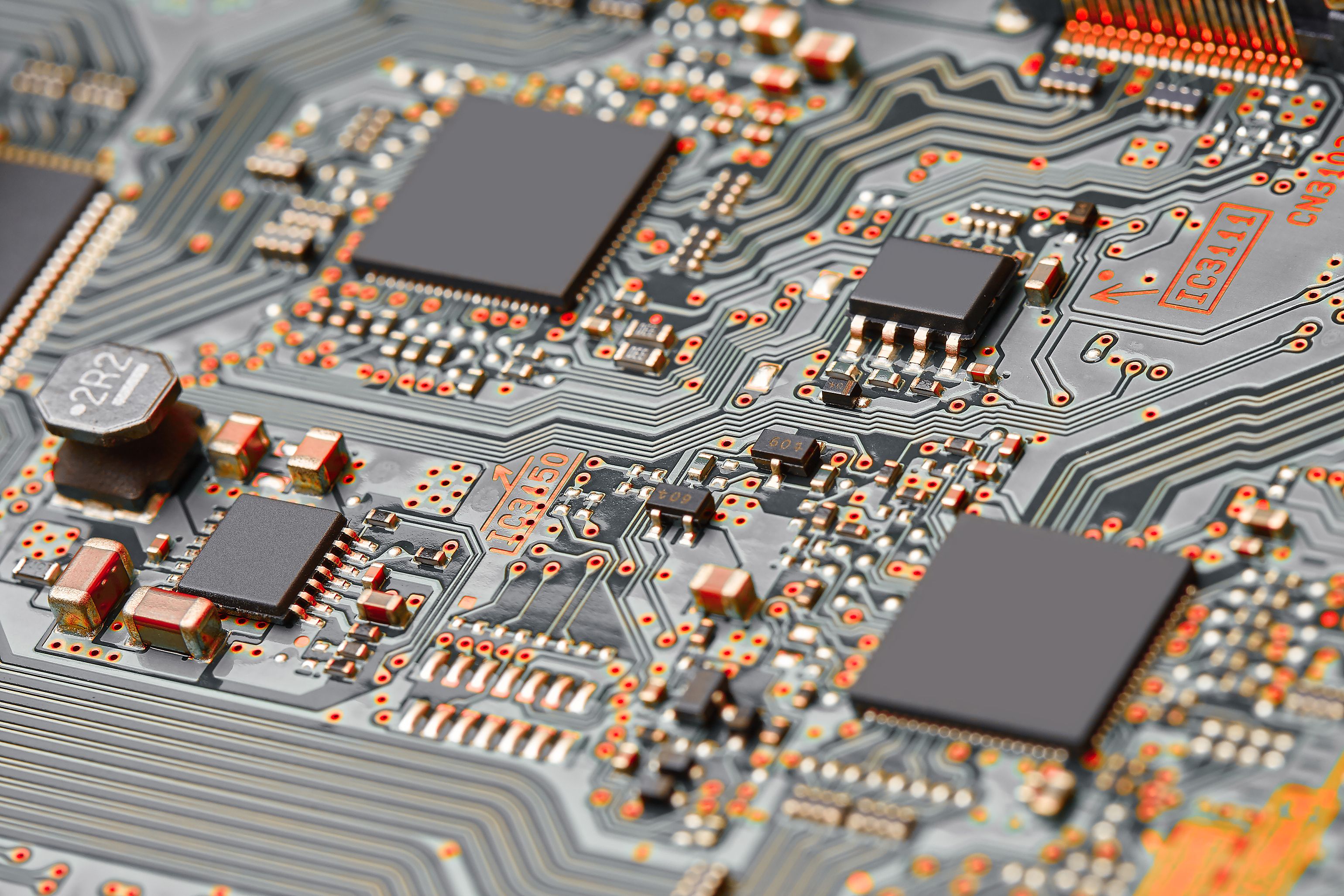

See below for developments related to E&I’s progress in enabling improved connectivity, power, functionality, and performance in support of the automotive and other industries.

Industrial News

See below for information on how E&I’s leading-edge technology enables specialty industrial materials for printing and display, healthcare, and other industrial applications.

Kalrez® Specialty Sealing

MOLYKOTE® Industrial & Specialty Lubricants

We’re here to help.

We love to talk about how our electronics solutions can build business, commercialize products,

and solve the challenges of our time.

Subscribe to receive the latest research & trends

By submitting, you agree to our Privacy Policy

www.pp.dupont.com/electronic-materials/contact-us.html?dfp=subscribe

-