Extreme Versatility and Thermal Performance Provides Unlimited Potential

From the circuits in the cameras on space missions to the next generation of photovoltaic cells, DuPont™ Kapton® polyimide films are helping make extraordinary new design possibilities actually happen.

For applications where extremes of heat and vibration are the norm, designers rely on Kapton® because of its ability to maintain its unique combination of mechanical properties under the harshest of conditions.

DuPont™ Kapton® polyimide films have set the industry standard for over 45 years in high performance, reliability and durability, with a unique combination of electrical, thermal, chemical and mechanical properties that withstand extreme temperature, vibration and other demanding environments.

Polyimide Film Products

-

Kapton® Polyimide films

Kapton® Polyimide films

Maintains its unique combination of mechanical properties under the harshest of conditions.

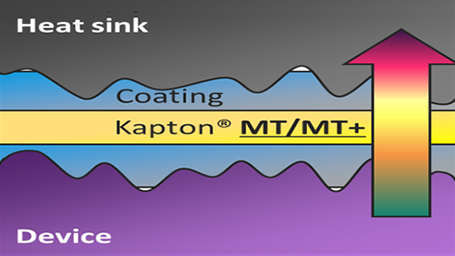

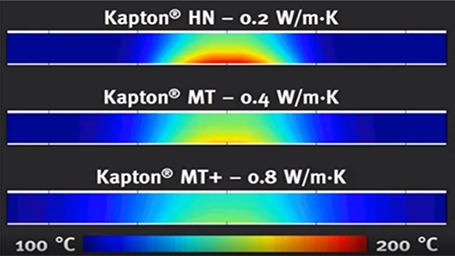

Film is treated on both sides and has an excellent balance of physical, chemical and electrical properties over a wide temperature range.Tough film that exhibits an excellent balance of physical, chemical and electrical properties over a wide temperature range, particularly at unusually high temperatures.Film is treated on both sides and has an excellent balance of physical, chemical and electrical properties over a wide temperature range.Preferred dielectric films for very fine pitch circuity and next generation IC packaging application.Film is treated on both sides and has an excellent balance of physical, chemical and electrical properties over a wide temperature range.General purpose HN film coated or laminated on one or both sides with a FEP fluoropolymer.Film is treated on both sides and has an excellent balance of physical, chemical and electrical properties over a wide temperature range.Film is treated on both sides and has an excellent balance of physical, chemical and electrical properties over a wide temperature range.Film is treated on both sides and has an excellent balance of physical, chemical and electrical properties over a wide temperature range.Recommended for applications that require an all-polyimide film with an excellent balance of properties over a wide range of temperatures.These films with thermal conductivity of 0.45 W/m·K can be used alone or combined with other materials as a laminate for added functionality. Kapton® MT film comes in a variety of thicknesses, even as thin as a little over 25µm.These films with superior thermal conductivity of 0.8 W/m·K are available as thin as 38 µm up to 127 µm. Lowers operating temperature by 20–45°C in e-motors as a NKN slot liner. Increases power output by 10-30% for PTC heaters.Film is treated on both sides and has an excellent balance of physical, chemical and electrical properties over a wide temperature range.Tough film that exhibits an excellent balance of physical, chemical and electrical properties over a wide temperature range, particularly at unusually high temperatures.Electrically conductive film for applications in which a precisely controlled surface resistivity is needed.Film is treated on both sides and has an excellent balance of physical, chemical and electrical properties over a wide temperature range. -

Important Information

Important Information

This list of literature below is not specific to one product grade

We’re here to help.

We love to talk about how our electronics solutions can build business, commercialize products,

and solve the challenges of our time.