Kalrez® O-rings for Hydrogen Sulfide Removal

Case Study

Amine treatment is a process typically used for Hydrogen Sulfide removal from natural gas (sour gas). This operation is commonly referred to as gas “sweetening”.

Amine units are used all over the world in oil refineries and gas plants to remove hydrogen sulfide (H2S) from a product stream. New environmental standards are stricter and require ever decreasing contents of H2S in clean natural gas. Most of the new sources of oil and gas discovered today have high contents of H2S which demand more efficient removal technologies (the Shah Gas field in the United Arab Emirates for example has up to 30% H2S).

Challenge

Amine units operate under harsh chemical environments. H2S for example, needs to be handled with care and can cause embrittlement of metal equipment. These processes also operate at high temperature where perfluoroelastomer sealing components are required. Amines, however, are known to be aggressive to many FFKMs. When elastomers are in contact with amines, they tend to swell to a high degree which results in a loss of mechanical properties and extrusion. This can lead to leakage, rupture of the fluid film in mechanical seals due to face seal deformation and an increase in torque needed to operate.

Solution

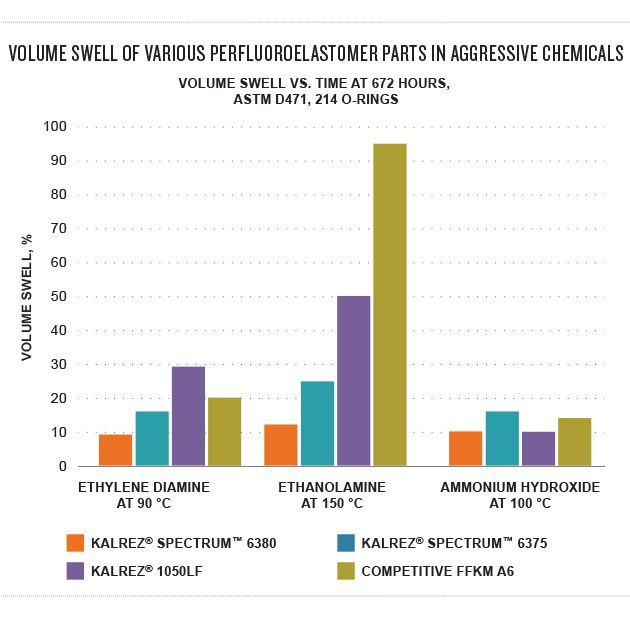

DuPont™ Kalrez® Spectrum™ 6380 perfluoroelastomer parts offer outstanding resistance to amines because it exhibits four times lower swell over general purpose perfluoroelastomer (FFKM) offerings.

The use of DuPont™ Kalrez® Spectrum™ 6380 parts in these applications may extend the MTBR (Mean Time Between Repairs) of valves and pump mechanical seals and reduce leakage which can help contribute to reduce maintenance costs and lower emissions. The latest Kalrez® 0090 parts represent another option for this application when high pressure resistance is needed. The following graph compares the chemical resistance of Kalrez® Spectrum™ 6380 to other sealing materials when exposed to a typical amine/water mixture used in gas sweetening units.

Ideas & innovations

Powered by a broad product portfolio and state-of-the-art expertise, we help our partners meet the critical industry demands of the electrical and electronics market.

Featured Kalrez® resources

Additional links

Kalrez® Chemical Resistance Guide

Literature

Kalrez® O-rings for mechanical seals in silicon chemicals

Kalrez® O-rings for pumps in paper mill industry

Kalrez® O-rings for glass tube manufacturing

Case Studies

Kalrez® O-rings-for-gas-sweetening valves

Kalrez® Spectrum™ 6375 O-rings for PTFE Replacement

Articles