Kalrez® Parts Heat Resistance

Article

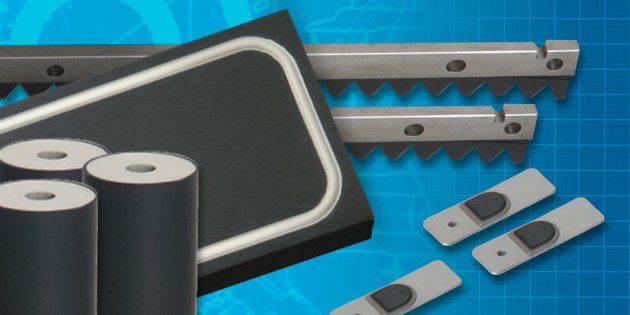

Kalrez® perfluoroelastomer parts last longer and seal more effectively than other elastomers due to their exceptional heat resistance. Longer-lasting seals can be a direct route to extended mean time between replacement and lower cost of ownership.

Heat Resistance

The outstanding thermal stability and excellent chemical resistance of perfluoroelastomer parts are due to the strength of its carbon-fluorine bond in the perfluorinated chain. Even after long-term exposure to temperatures up to 327°C, Kalrez® parts retain elasticity and recovery properties better than other high temperature elastomers. They resist hardening and embrittlement, the principal heat-related cause of seal degradation and failure. And in high-vacuum semiconductor applications, Kalrez® parts exhibit negligible outgassing over a wide temperature range.

Low Compression Set

Kalrez® parts exhibit low compression set, maintaining their elastic recovery to maintain tight seals over the long haul. Because Kalrez® parts recover better under compression than other perfluoroelastomers, they maintain their shape better under prolonged stress.

Ideas & innovations

Powered by a broad product portfolio and state-of-the-art expertise, we help our partners meet the critical industry demands of the electrical and electronics market.

Featured Kalrez® resources

Additional links

Kalrez® Chemical Resistance Guide

Literature

Kalrez ®O-rings for mechanical seals in silicon chemicals

Kalrez® O-rings for pumps in paper mill industry

Kalrez® O-rings for glass tube manufacturing

Case Studies

Kalrez® O-rings-for-gas-sweeteningvalves

Kalrez® O-rings Used in Pressurized Water Reactor

Kalrez® Spectrum™ 6375 O-rings for PTFE Replacement

Articles

Kalrez® Seal Outgassing Test Results in Wafer Processings