Vespel® Polyimide Parts and Shapes:

Trusted in Extreme Conditions and Demanding Environments

Temperature extremes, high friction, and heavy loads? Vespel® has outperformed other engineering materials under the most severe conditions since 1965.

For highly demanding applications like aerospace components, semiconductor processing, automotive manufacturing, and energy production rely on Vespel® parts to keep their equipment running.

Outstanding temperature, mechanical and PV properties.Vespel® polyimide parts and shapes provide continuous operation at cryogenic to high temperatures; low wear and low friction at high PV in lubricated or unlubricated environments; outstanding creep, strength, and impact resistance; exceptional dimensional stability; low thermal expansion; and easy machinability.

Vespel® makes lighter weight parts not only practical, but, in many cases, better than standard metal, ceramics, and other engineering polymers such as PEEK (polyether ether ketone) and PAI (polyamide-imide).

Global solutions. With design centers in Asia, Europe, and the Americas, Dupont Engineers and Scientists collaborate with customers to combine materials science with design to produce high-performance parts and keep production running smoothly.

Wide range. Vespel® parts and shapes, both custom and stock, have been tested and proven effective in highly demanding applications around the globe. They are available in sheet, rod, tube, plaque, bar, disk, ring, ball, direct formed and custom machined parts.

Uses

- Bearings, bushings, insulators, seals, thrust washers, and wear rings

- Wear pads, wear strips, and tube clamps

- Thermoplastic injection-molded, assembled, and composite parts

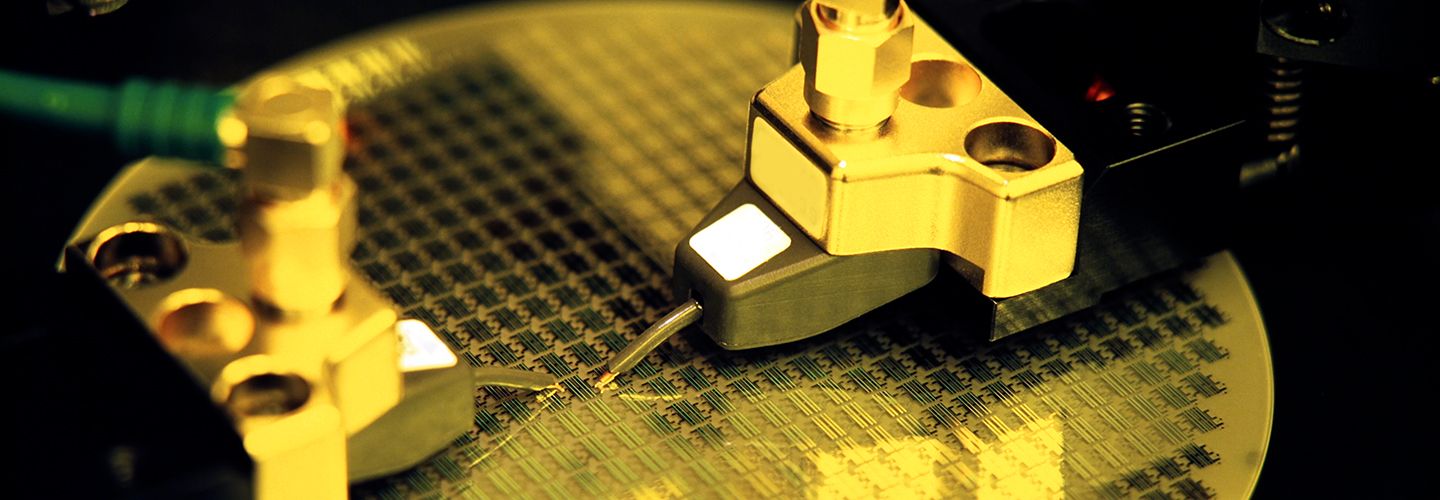

- Test sockets and wafer guides

- Glass handling technology

- Wear components in centrifugal pumps

- Hydrocarbon, chemical, and water service pumps

Advantages

- Low creep and low out-gassing

- Lightweight yet handles high loads

- Chemical, electrical, wear, and thermal resistance

- Strength, stiffness, and dimensional stability

- Easy to machine and can be machined to very close tolerances

- Works well under hard vacuum, radiation, oxygen compatibility, cryogenic conditions, and exposure to flame

- Costs less to manufacture than ceramic

Industries

Aerospace

Aerospace and commercial aviation customers turn to us for innovative solutions that help them solve specific challenges like weight reduction, improved durability and reliability and more.

Enabling high-speed, reliable, next-generation electrical and electronics connections for today’s “always on” world

Performance benefits

Aircraft Engine Externals

DuPont™ Vespel® can help solve tough sealing, wear, friction, vibration and thermal endurance challenges for aircraft engine externals.

Vespel® Aircraft Engine Fan Blade Material

DuPont™ Vespel® offer proven strength, wear resistance, and low friction for aircraft fan blade wear strips and blade spacers.

Engine Components

DuPont™ Vespel® parts offer long-lasting performance at high temperatures with low friction and wear, making them ideal for bushings, washers, and seal rings.

Turbochargers

DuPont™ Vespel® parts help reduce emissions, while resisting heat and providing thermal insulation, making them ideal for turbochargers and EGR systems.

Semiconductor Manufacturing Back End

Dimensionally stable DuPont™ Vespel® parts are ideal for wafer handling and chip testing – they offer low wear and won’t damage wafers like metal or ceramic.

Aircraft Engine Nacelle Design

DuPont™ Vespel® improves aircraft engine nacelle performance with proven shear strength, impact resistance and weight savings.

Vespel® Engine Oil System Seals

DuPont™ Kalrez® O-rings, gaskets and custom seals stand up against jet fuel, engine lubrication oils, hydraulic fluids, rocket propellants and oxidizers.

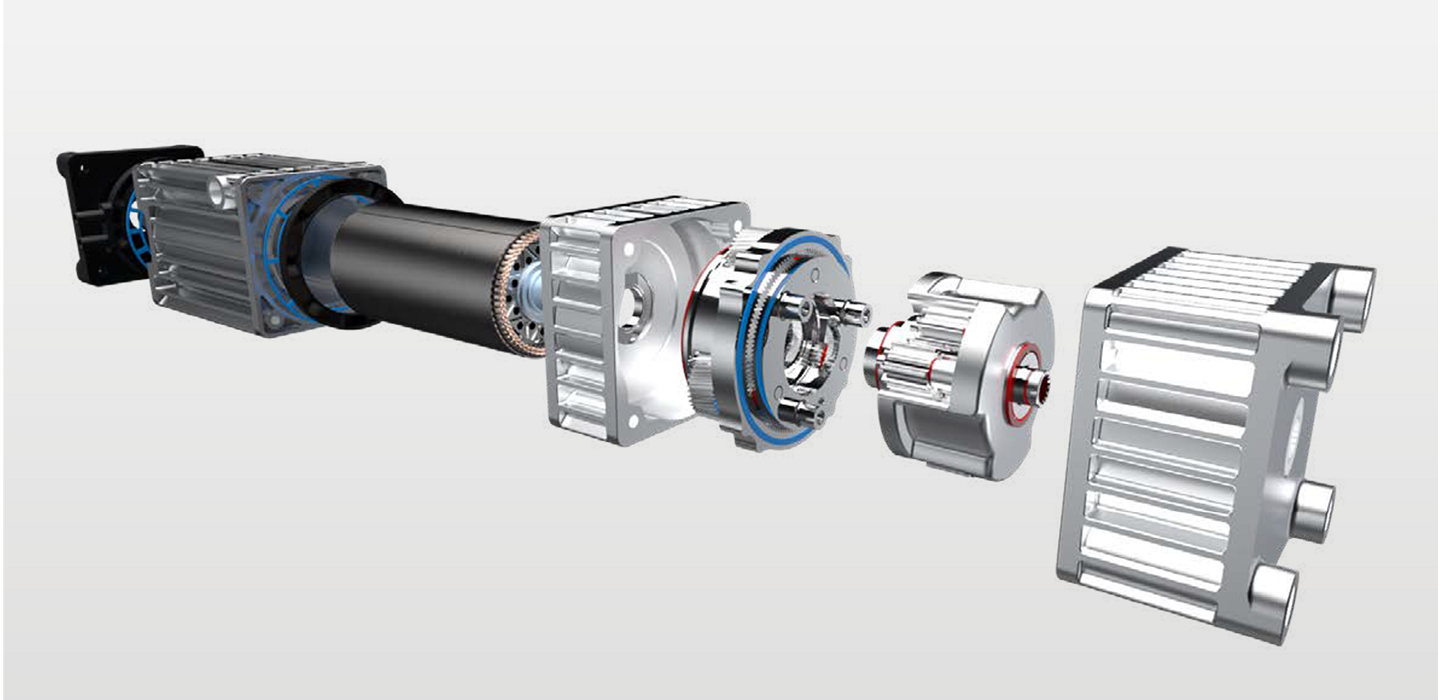

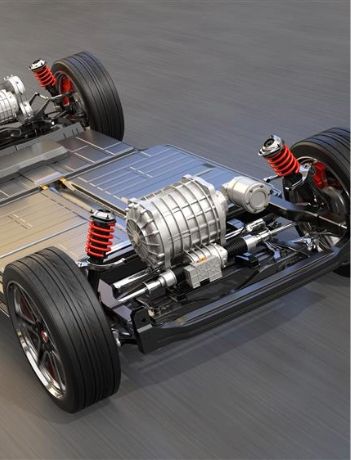

Powersport Vehicles

DuPont™ Vespel® clutch components offer toughness, low wear under high friction and impact resistance, making them ideal for ATVs, motorcycles, and more.

Aircraft Engine Nacelle Design

DuPont™ Vespel® improves aircraft engine nacelle performance with proven shear strength, impact resistance, weight savings, and high heat resistance.

Driveline Components

High-performance Vespel® driveline components help control friction, limit wear, and reduce risk of seizure

Solutions

Ideas & innovations

Powered by a broad product portfolio and state-of-the-art expertise, we help our partners meet the critical industry demands of the electrical and electronics market.