VW battery pack enhanced by BETAMATE™ 2090

Case Study

Project

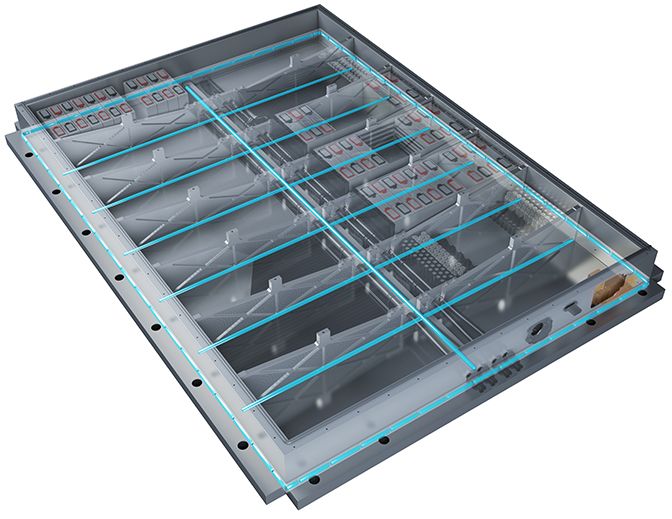

Supplier partners, like DuPont, are crucial to Volkswagen’s efforts to transform from combustion engines to electric versions of all their vehicles across all brands between 2019 and 2030. The modular electric drive matrix (MEB) platform relies heavily on the performance of the battery pack. It is essential that the battery pack frame is strong and crash resistant to protect the battery cells, and more importantly, vehicle occupants. When it came to the decision to utilize a structural adhesive for this important application, the excellent relationship between Volkswagen and DuPont helped to quickly develop the right material at the right time — BETAMATE™ 2090 structural adhesive.

Challenges

Volkswagen’s challenges for battery pack assembly were two-fold. First, the solution had to provide durability, stiffness, and crash performance. Second, manufacturing process flexibility had to be enhanced. Mechanical joining could not ensure a continuous bondline, thus sacrificing structural integrity. In addition, long welding lines could not achieve the desired cycle time. Once the decision was taken for an adhesive solution, there was the further challenge of needing one-part curing performance with a cold-cure, two-part adhesive due to the lack of an oven in the assembly line for a heat-cured process. And, no surface pre-treatment was a requirement to save time and cost.

Solution

Known for best-in-class engineered chemistry and application knowhow, DuPont’s R&D and technical service teams were able to quickly provide a solution by modifying existing technology to develop BETAMATE™ 2090 structural adhesive.

The product exhibits:

• Strength and stiffness

• High elastic modulus

• Primerless technology for no surface pretreatment

• Curing kinetics allowing for 20-minute open time to achieve handling strength

• Non-oven curing

• Ability for robotic or manual application

These attributes help ensure battery pack frame structural integrity that demonstrates stiffness, durability, and crash performance while delivering process efficiencies that simplify the manufacturing process and shorten cycle times. An additional benefit is the ability to use the same material for battery pack repair.

Result

BETAMATE™ 2090 structural adhesive is being specified on the VW MEB platform for several models of electric vehicles now in production, including the Volkswagen ID.3.