XPS vs. ISO: A better choice for below grade

ISO and XPS foam – what’s the difference?

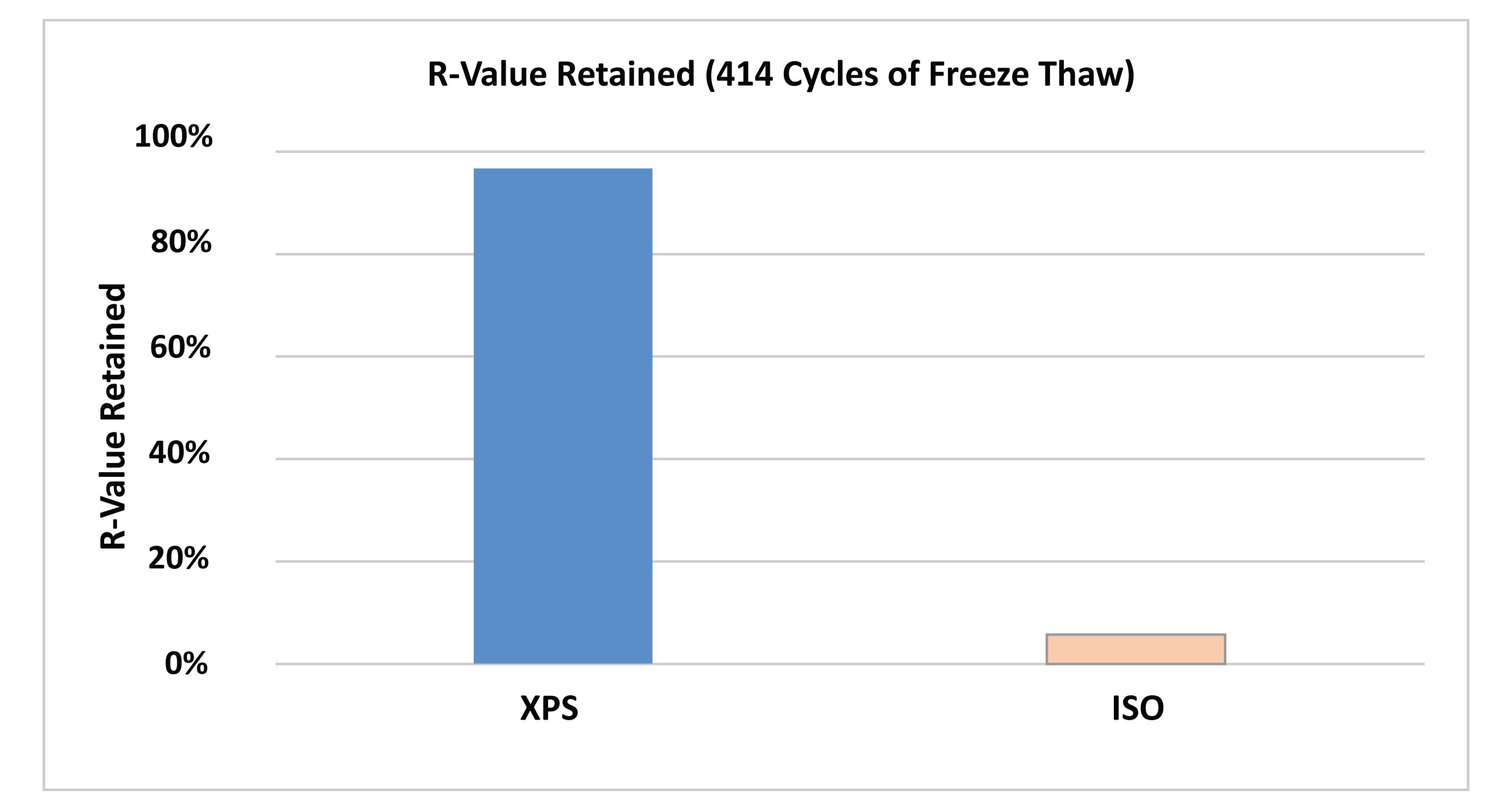

Unfaced polyisocyanurate (polyiso or ISO) foam does not have the same moisture, thermal or compressive strength properties as Styrofoam™ Brand XPS. For below-grade applications likely to encounter wet, low-temp as well as heavy construction equipment, Styrofoam™ Brand XPS has proven to stand the test of time over and over again.

ISO and XPS foam – what’s the difference?

R-Value Retention

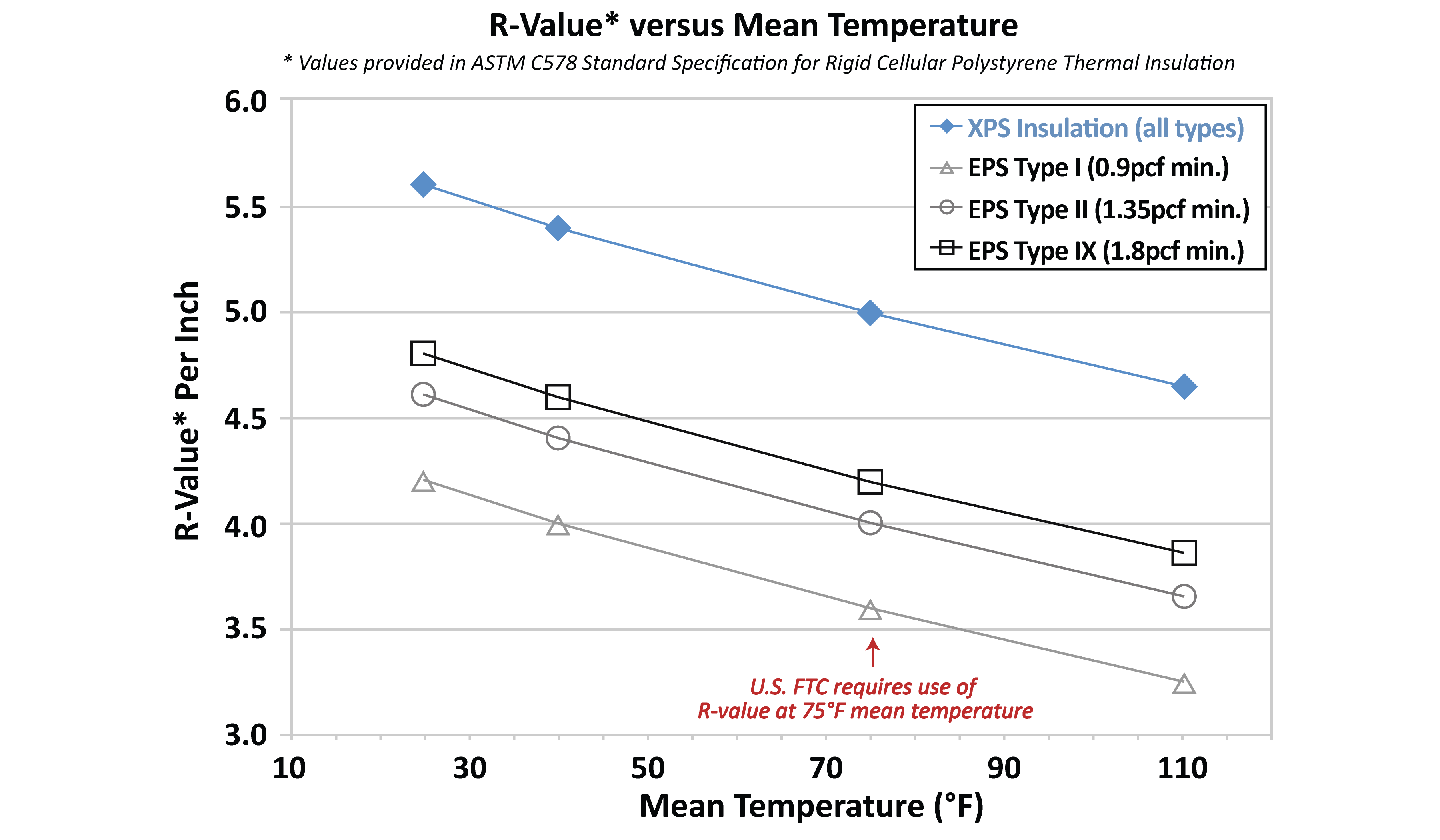

DuPont™ Styrofoam™ Brand XPS can outperform other insulation materials in maintaining R-value, even in extremely cold temperatures.

See chart

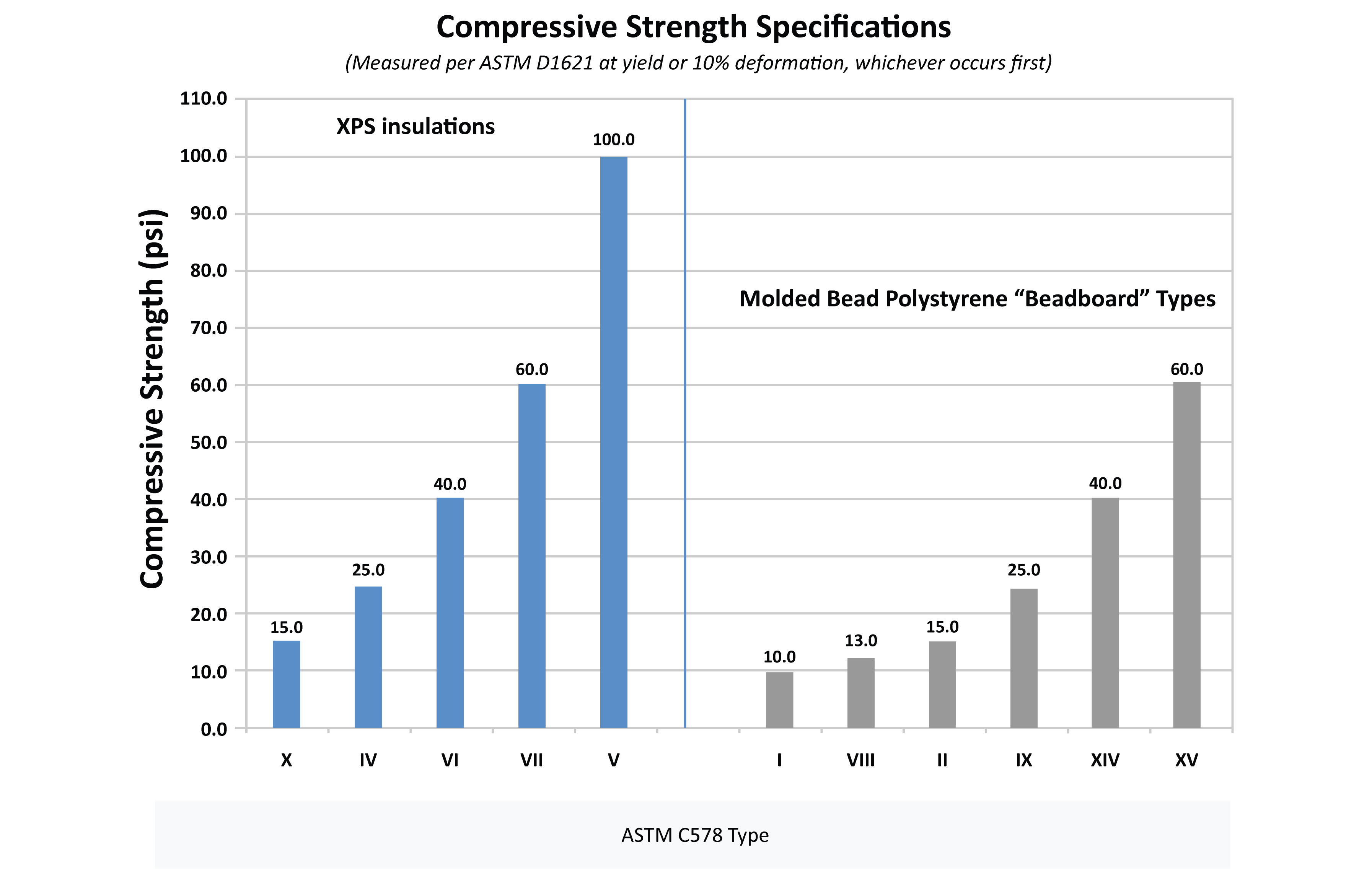

Compressive Strength Options

Styrofoam™ Brand XPS offers a variety of compressive strengths for both horizontal and vertical below-grade applications.

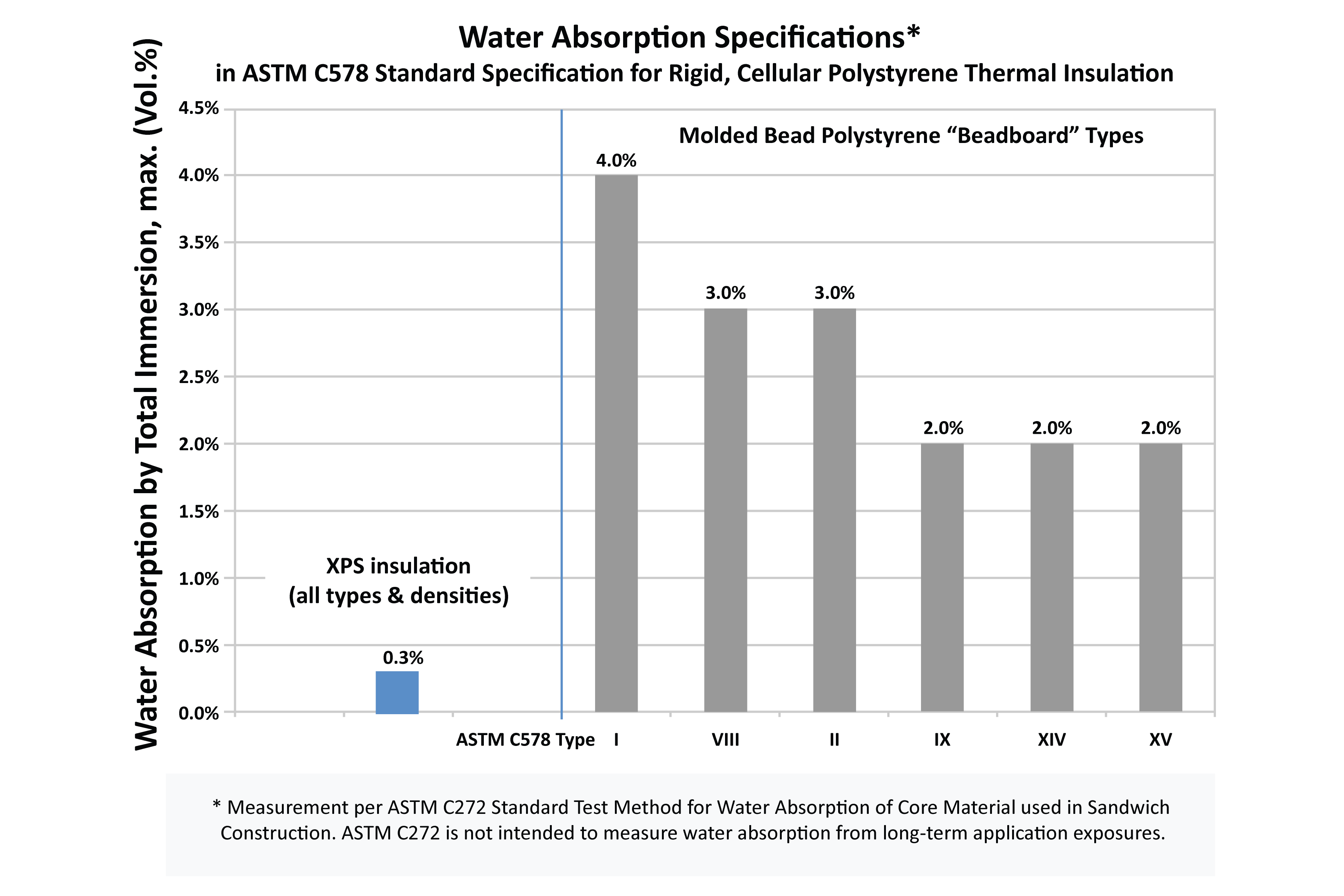

Lower Moisture Absorption

Styrofoam™ Brand XPS has significantly better moisture absorption properties, with only 0.1% absorption.1 Resilience to Long-Term Water Exposure Styrofoam™ Brand XPS delivers top performance and durability even in harsh conditions.2

Convenience

Styrofoam™ Brand XPS cuts easily and cleanly with a score and a snap, resulting in minimal mess and waste.

Technical information

Below-Grade Efficiency: Maximizing Performance with

Styrofoam™ Brand Insulation

A unique closed-cell structure gives Styrofoam™ Brand XPS its exceptional moisture resistance and enables it to retain a high, long-term R-value of R-5 per inch – even after exposure to standing water, wet soil and other damp conditions

Additional performance attributes of Styrofoam™ Brand XPS include:

- Meets ASTM C578 Types (refer to specific product information for details)

- Compliant with ICC-ESR 4755

- Provides a weather-resistant barrier to enhance the building’s resistance to air and moisture penetration

- Meets building code requirements of ASTM E84 Flame Spread Index of 25 or less and a Smoke Developed Rating of 450 or less

- Will not corrode, rot or support mold growth

- Available in wide range of compressive strengths from 15 to 100 psi, and minimum flexural strength of 40 psi

- Offered in various sizes, thicknesses and edge treatments to meet specific design needs, while ensuring energy efficiency and minimizing on-site cutting and waste

DuPont™ Styrofoam™ Brand XPS products are backed by the expertise of building science leaders dedicated to your success and warranties from a name you trust, including limited thermal warranties from 15 to 50 years including the Wall² system warranties and other system warranties.

Any questions?

The Styrofoam™ Brand was the original XPS, creating the product segment. Rooted in 80+ years of technical innovation, we’re excited to deliver a low-GWP XPS solution.

Let’s start a conversation about your next project.

Resources

Styrofoam™ Brand XPS Compliance Letter

U.S. AIM Act & Sell-through of Styrofoam™ Brand XPS Foam Insulation (2025)

Physical Property Equivalency Letter

Customer Processing and Transport Safe Handling

Safe Processing & Handling Graphic

Styrofoam™ Brand Product Brochure

Solar Exposure Technical Bulletin

Press Releases

September 9, 2024

English press release →

November 30, 2023

English press release →

June 8, 2023

English press release →

June 6, 2023

English press release →

July 26, 2021

English press release →

February 23, 2021

English press release →

August 13, 2020

English press release →

French PDF ↓

July 16, 2020

English press release →

French PDF ↓

Styrofoam™️ Brand Low GWP XPS LEED Optimization Document - Embodied Carbon Assessment

1 Typical value tested per ASTM C272, % by volume.

2Billy Connor, April 2019. “Comparison of Polystyrene Expanded and Extruded Foam Insulation in Roadway and Airport Embankments”. Alaska University Transportation Center, University of Alaska Fairbanks, (INE/AUTC 19.08). http://autc.uaf.edu/projects/2019/comparison-of-polystyrene-expandedand-extruded-foam-insulation-in-roadway-and-airport-embankments/