Effective Solutions for Bearing Insulation to Prevent Electrical Corrosion in E-Drive Systems

Author:

| Philippe Pauchard, Application Engineer at DuPont (Switzerland) |

Christoph Berger, Application Development Manager, DuPont (Germany) |

Ruth Jackowiak Application Engineer at DuPont (Switzerland) |

Source:

CTI magazine

The automotive industry is progressing toward high-voltage systems for electric vehicles (EVs) with enhanced efficiency. Reliable and durable com-ponents are increasingly critical, particularly bearings in electric motors, which can suffer from electrical erosion due to parasitic currents, causing significant damage and premature failure. This challenge is addressed by using insulation provided by DuPont™ Vespel® polyimide parts.

Electric erosion in bearings

In traction motors, parasitic current can move through the roller bearings and cause damage. The bearing failure mechanism is called electrical erosion. An electrical discharge between the rolling element and a bearing raceway creates spot welds between the surfaces. With the ongoing rolling motion, those spot welds break apart and small particles are generated, causing additional wear of the surfaces.

Electrical erosion occurs in modern high-speed electric motors, in regenerative braking systems of electric vehicles, or wherever Variable Frequency Drive (VFD) are used to control a motor. The worst-case scenario of electrical erosion in bearings is the premature failure of the electric motor, which can lead to safety hazards, and significant costs associated with repairs.

Risk Reduction methods

Preventing parasitic currents through system design would be the ideal solution, but this remains a significant challenge. While future inverter technologies may eventually mitigate the risk of voltage spikes, the cost-effectiveness for high-volume applications is still questionable. Alternative solutions, such as Insulated-Gate Bipolar Transistors (IGBTs) or gallium nitride-based switches, offer potential benefits but seem to be either limited in efficiency or still too expensive for widespread use. Moreover, their effectiveness in preventing electrical erosion can only be assured when the entire system is designed and manufactured by a single supplier. Once subsystems from different sources are integrated, predicting the system’s behavior becomes increasingly complex.

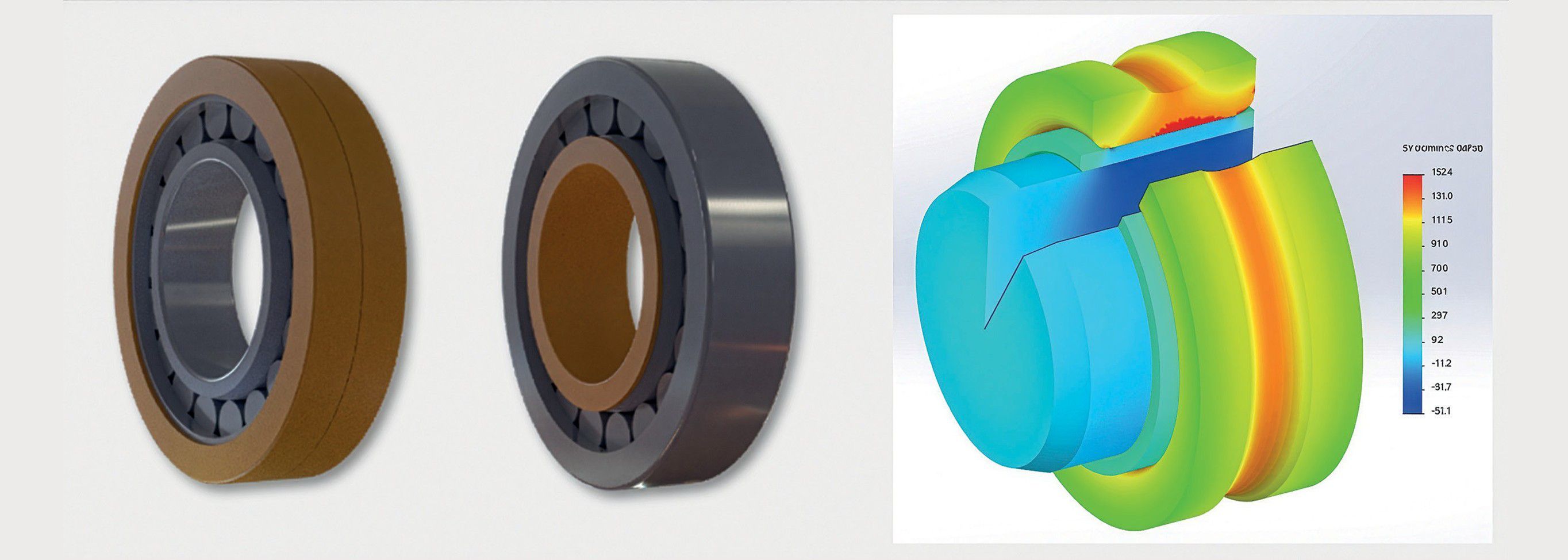

FIGURE 1 Vespel® bearing insulation sleeves (left) and Stress analysis of the Vespel® sleeve press-fitted over the shaft and assembled on the inside diameter of the bearing (right).

Vespel® polyimide insulating bearing sleeves

Vespel® S is a sintered polyimide which has no observable glass transition temperature or melting point. Its high-temperature resistance allows it to be used as an insert in die-cast aluminum parts. Its unique property is key for applications where high loads and elevated temperatures can occur, as may be the case in traction motors in critical drive modes or in the case of malfunction.

Vespel® polyimide insulating bearing sleeves, can be used to electrically insulate the rotor from the housing and suppress discharge currents. They offer a versatile and cost-effective solution for mitigating electrical corrosion in e-motor bearings. These sleeves can be installed during final assembly by press-fitting onto either the rotor shaft or one of the bearing rings (Figure 1). In all cases, standard steel ball bearings can be utilized with Vespel® sleeve, eliminating the need for expensive ceramic rolling elements such as hybrid bearings.

Vespel® polyimide insulating layer between 1 and 2 mm offers robust insulation by significantly increasing electrical impedance. This effectively attenuates high-frequency currents traversing the bearing, thereby reducing the risk of electrical erosion. Vespel® polyimide also exhibits mechanical damping properties that may help reduce noise, vibration, and harshness (NVH) in electric motor systems.

Existing solutions, such as ceramic and polymeric coatings provide adequate insulation in DC environments, they often fail to prevent electrical discharge under AC conditions, particularly at higher frequencies, and may suffer from mechanical fragility.

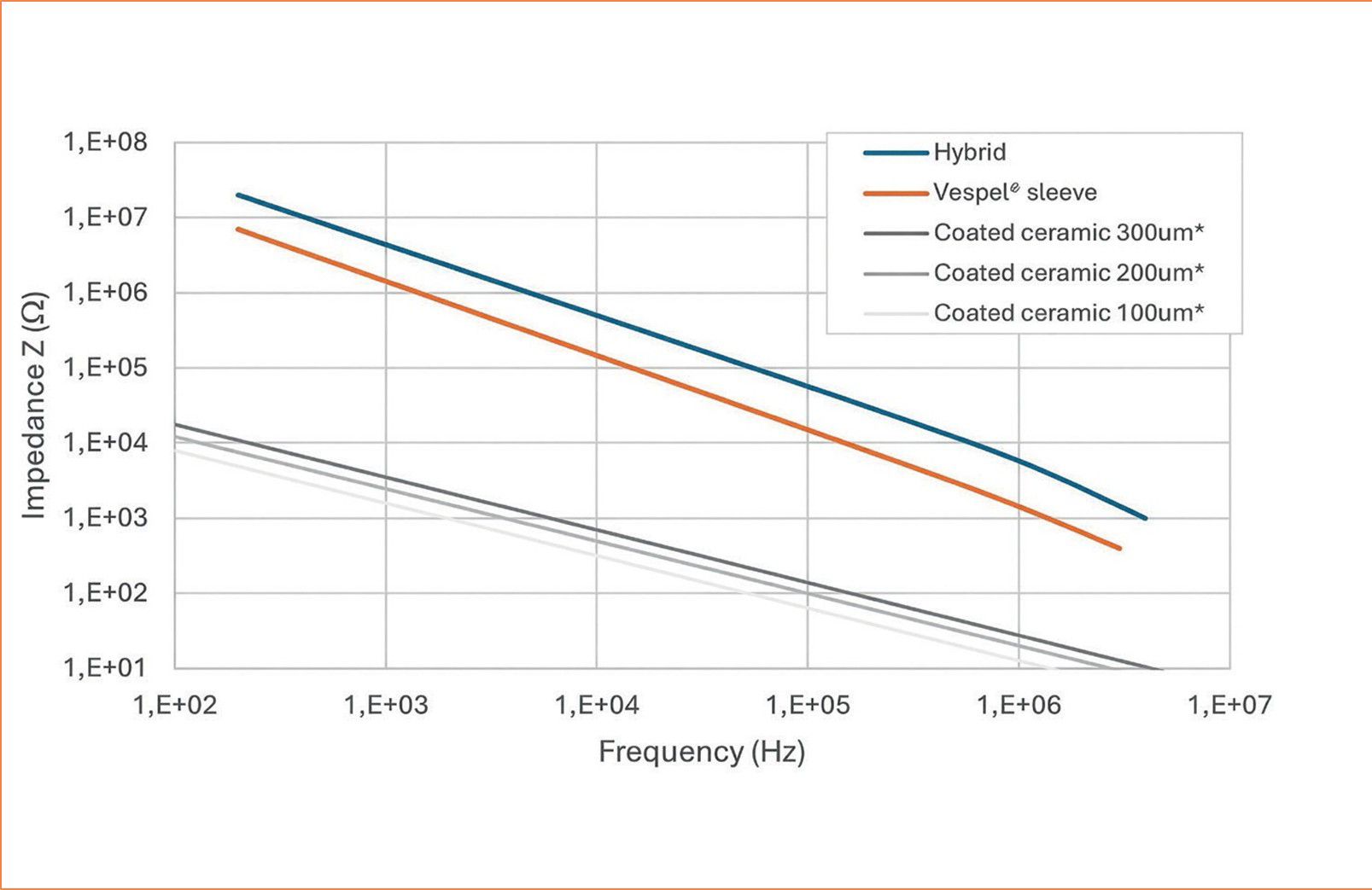

Electrical insulation performance

Various tests have been conducted to support the use of Vespel® sleeves in addressing electrical corrosion issues. The electrical impedance has been measured by IMKT (Institut für Maschinen-konstruktion und Tribologie at Leibniz Universität Hannover). Results indicate that the electrical insulation performance of Vespel® SP-1, although slightly lower than that of the hybrid bearing, remains in the same order of magnitude and significantly higher than the ceramic-coated bearing solution [8], even when compared to the thickest layer of ceramic coating (Figure 2).

FIGURE 2 -Comparison of Electrical Impedance Across Various Insulated Bearing Solutions

Designing Vespel® polyimide Insulating sleeve

The design of the Vespel® polyimide sleeve requires studying the different press-fitting scenarios and checking that the loads resulting from the press-fitting of the various parts, combined with thermal expansion, are acceptable (Figure 1). Bearing manufacturers typically provide maximum hoop stress and radial stress; this information is used to properly dimension the Vespel® polyimide sleeve. Although proper testing needs to be conducted on the final system to ensure the parts behave appropriately, simulations are used to build confi-dence and quickly design a working prototype (Figure 1).

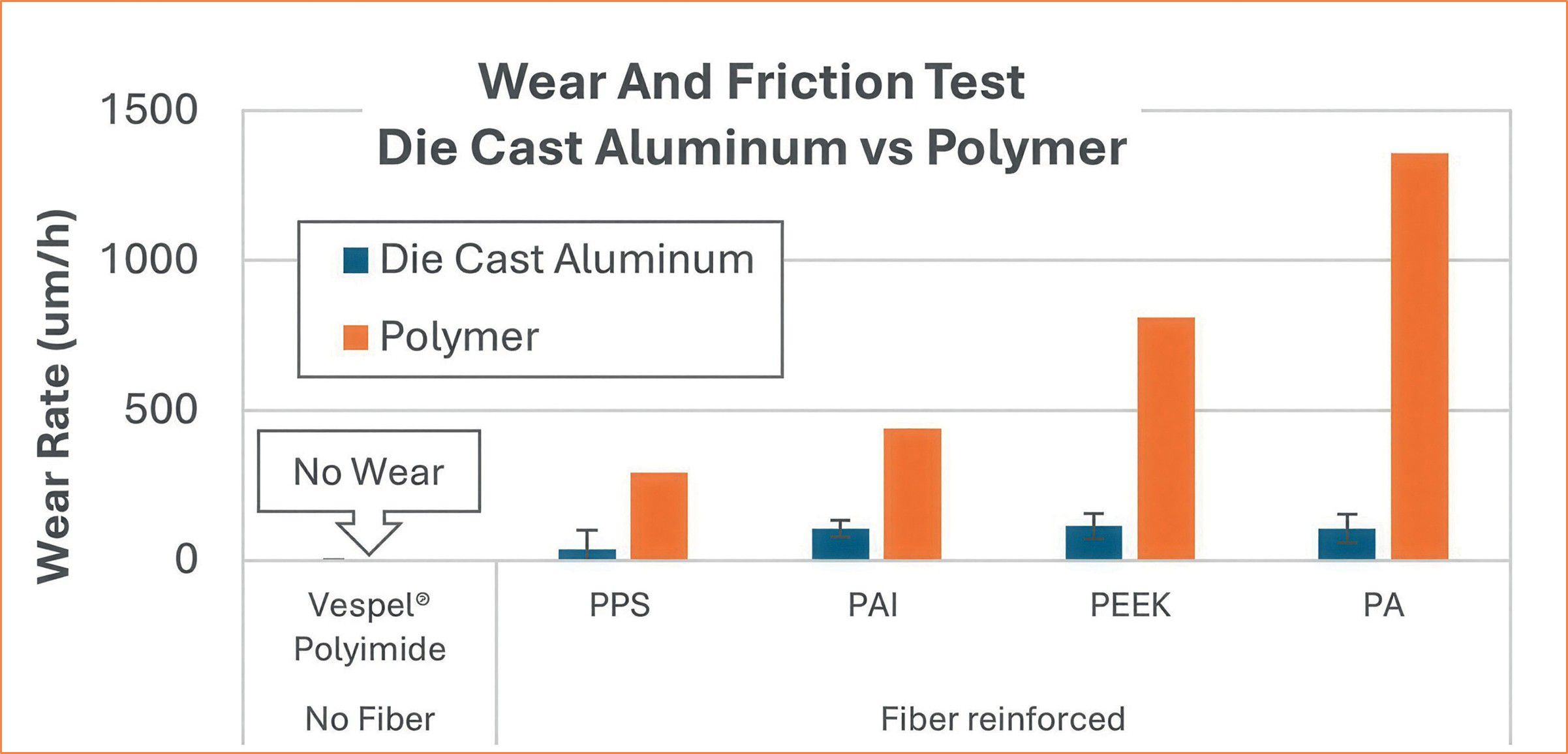

Other polymeric solutions could be used, but they need to be reinforced with fibers to enhance mechanical strength. The fibers are abrasive and easily cause wear issues when they are in contact with aluminum. In EV cars, this phenomenon is amplified with the vibration generated by electrical motors causing fretting wear issues on aluminum housing.

Unlike standard polymers, Vespel® polyimide, with extreme temperature capabilities, does not require fiber reinforcement to maintain its mechanical performance and withstand the maximum temperature of 150°C, observed at the bearing position for traction motors. Tests conducted at the DuPont Tribological Laboratory under similar conditions revealed that fiber-reinforced thermoplastics caused significant wear on aluminum components, whereas Vespel® polyimide resulted in no measurable wear (Figure 3).

FIGURE 3 Wear performance of Vespel® polyimide vs polymeric solution against die cast aluminum

Aluminum die-casting insert

Another innovative solution involves the use of Vespel® polyimide as an insert in aluminum die-casting, leveraging its exceptional high-temperature resistance and lack of a melting point, which enables it to withstand aluminum processing temperatures up to 680 °C. By integrating a Vespel® insert directly into the mold, an electrically insulating barrier is formed between the traction motor housing and the bearing. Following the die-casting process, the insert can be machined to achieve precise tolerances – a standard step prior to bearing assembly.

In collaboration with Swiss aluminum die caster Aluwag AG, the feasibility of this concept was successfully demonstrated through the production of aluminum housings incorporating a 90 mm diameter Vespel® insert (Figure 4). Notably, the interface exhibited no structural or dimensional changes after multiple thermal cycles ranging from –40 °C to 150 °C, underscoring its suitability for long-term use in demanding application environments.

FIGURE 4 Cross section of bearing seat with Vespel® insert (© DuPont)

Recyclability of aluminum components with Vespel® polyimide inserts

Die cast aluminum housings containing Vespel® polyimide inserts are currently being evaluated by companies for use in electric vehicle driveline components. In addition to performance testing, there is a need to recycle aluminum housings that exhibit defects. During the casting process, a skimming operation is typically performed to eliminate impurities such as oxides, slag, and other contaminants that form at the surface of the molten aluminum. Preliminary tests have shown that Vespel® polyimide components float on the surface of the molten aluminum, which could simplify their removal during the skimming operation.

Most electric motor housings use steel sleeves to protect aluminum from bearing-induced fretting wear. However, these inserts complicate recycling due to material separation. Vespel® polyimide could offer a more sustainable alternative, replacing steel sleeves used with ceramic bearings while maintaining electrical insulation and simplifying recycling.

FIGURE 5 Vespel® Inserts Floating on the Surface of Melted Aluminum

SUMMARY

As electric vehicles evolve, the need for reliable and durable components, particularly bearings, is paramount due to their susceptibility to electrical erosion in high-voltage systems. DuPont™ Vespel® polyimide offers a groundbreaking solution with its insulating bearing sleeves, which can enable the use of standard roller bearings instead of costly ceramic alternatives, thereby helping to reduce material costs significantly.

Additionally, Vespel® polyimide inserts can be integrated within aluminum die-casting processes, providing effective electrical insulation and enhanced performance in demanding environments. The combination of these innovative solutions positions Vespel® polyimide as an essential material for the future of electric vehicle technology, promoting safer, more efficient, and sustainable electrified drivetrains.

REFERENCES

[1] Rösel, G.; Moenius, P.; Daun, N.; Spas, S.; Hackmann, W.; Schmitt, B.; Reich, A.: Konzept für einen Hocheffizienten 800 V Achsantrieb. 41st International Vienna Motoren Symposium, Vienna, 2020

[2] Power Electronics New Zealand: The principles of managing dV/dT in AC variable frequency drives. Online: https://www.power-electronics.co.nz/blog/the-principles-of-managing-dvdt-in-ac-variable-frequency-drives/, access: August 13, 2024

[3] Saucedo-Dorantes, J.; Zamudio-Ramirez, I.; Cureno-Osornio, J.; Osornio-Rios, R. A.; Antonino-Daviu, J. A.: Condition Monitoring Method for the Detection of Fault Graduality in Outer Race Bearing Based on Vibration-Current Fusion, Statistical Features and Neural Network. Online: https://www.mdpi.com/2076-3417/11/17/8033, access: July 17, 2024

[4] NTN: Elektroerosion. Online: https://waelzlagerwissen.de/waelzlagerschaeden/elektroerosion/, access: July 17, 2024

[5] Franquelo, L. G.; Rodriguez, J.; Leon, J. I.; Kouro, S.; Portillo, R.; Prats, M. A. M.: The age of multilevel converters arrives. In: IEEE Industrial Electronics Magazine 2 (2008), No. 2, pp. 28-39

[6] Eireiner, D.; von Petery, G.; Völkel, F.: Bearings Reinvented – Contribution of Rolling Bearings to Improving Ranges and Charging Times of Electric Vehicles. 20th International VDI Congress Dritev – Drivetrain for Vehicles, 2020

[7] Preisinger, G. Cause and Effect of Bearing Currents in Frequency Converter Driven Electrical Motors: Investigations of Electrical Properties of Rolling Bearings. Ph.D. Thesis, TU Wien, Vienna, Austria, 2002

©2025 DuPont. All rights reserved. DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, ℠ or ® are owned by affiliates of DuPont de Nemours, Inc. unless otherwise noted. DuPont believes this information to be reliable. It may be subject to change as additional knowledge and experience are gained. It is not intended as a substitute for any testing you may conduct to determine for yourself the suitability of our products and information for your particular purpose. Since conditions for use are outside the DuPont’s control, DUPONT DE NEMOURS, INC. AND ITS AFFILIATES MAKE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE AND ASSUMES NO LIABILITY IN CONNECTION WITH ANY USE OF THIS PRODUCT

AND INFORMATION. This information is not intended as a license to operate under or a recommendation to infringe any trademark, patent or technical information of DuPont or other persons covering any material or its use.