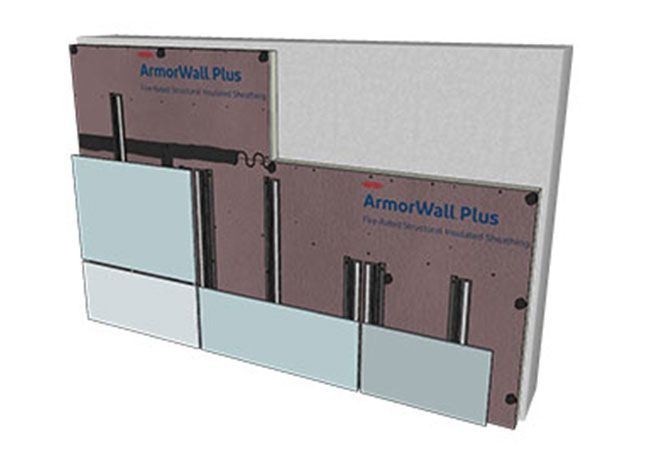

DuPont™ ArmorWall™ SP Plus Fire-Rated Structural Insulated Sheathing

5-in-1 Composite Panel for DuPont™ ArmorWall™ System

DuPont™ ArmorWall™ SP Plus Fire-Rated Structural Insulated Sheathing

5-in-1 Composite Panel for DuPont™ ArmorWall™ System

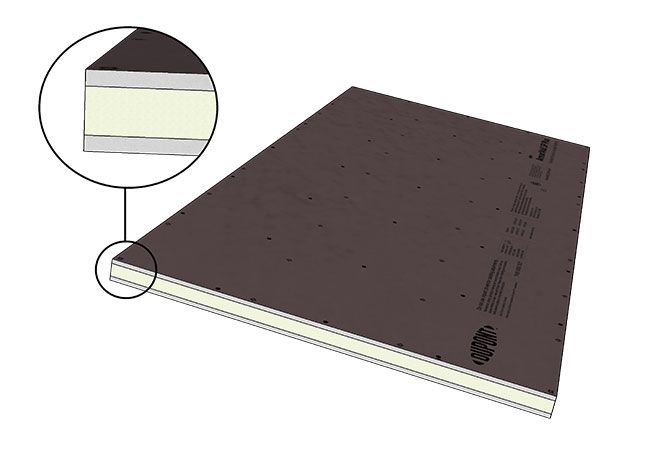

<br /><b>DuPont™ ArmorWall™ SP Plus Fire-Rated (FR) Structural Insulated Sheathing (SIS)</b> is an exterior wall sheathing product that has undergone rigorous ICC testing, with up to a two-hour fire rated assembly achievable. The unique feature of <b>ArmorWall™ SP Plus FR SIS</b> is that in addition to having a Magnesium Oxide (MgO) Sheathing material layer on the exterior face, it has an added layer of MgO sheathing on the interior face, which encapsulates the rigid foam insulation. This additional layer of sheathing, made from a naturally occurring fire-resistant mineral, gives <b>ArmorWall™ SP Plus FR SIS</b> added fire-resistance versus the Plus version. <br /><br />It also provides a factory-applied, air and water-resistive barrier on both the exterior and interior sheathing, which once sealed, makes the enclosure "dried-in," allowing for the commencement of interior construction, irrespective of the final exterior finish's status. <b>ArmorWall™ SP Plus FR SIS</b> is an all-in-one panel product that combines five traditional building enclosure elements: structural sheathing, fire-resistance, air barrier, water-resistive barrier, and a high-performance continuous insulation layer, making it a cost-saving and labor-reducing option compared to traditional, individual components.

Features & Benefits

Specifications

Standard Sizes

| Thickness | Sheathing Thickness | Insulation Thickness | Width | Length | R-Value | NetWeight |

|---|---|---|---|---|---|---|

| 2 3/4 in. | 1/2 in. + 1/2 in. | 1 3/4 in. | 4 ft. | 8 ft. | 11 | 185 lbs |

| 3 3/4 in. | 1/2 in. + 1/2 in. | 2 3/4 in. | 4 ft. | 8 ft. | 17 | 199 lbs |

| 4 1/4 in. | 1/2 in. + 1/2 in. | 3 1/4 in. | 4 ft. | 8 ft. | 21 | 203 lbs |

Testing

<b>DuPont™ ArmorWall™ SP Plus Fire-Rated Structural Insulated Sheathing,</b> when used as an approved DuPont commercial wall system, meets various ASTM Testing Standards. Applicable standards include:

| TEST METHOD | TEST TITLE | PROPERTY | RESULTS |

|---|---|---|---|

| FIRE | |||

| NFPA 2851 | Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components | Fire Resistance | PASS |

| ASTM E84 | Standard Test Method for Surface Burning Characteristics of Building Materials | Flame Spread/Smoke Developed Index (MgO Board) | 0 / 0 |

| ASTM E84 | Standard Test Method for Surface Burning Characteristics of Building Materials | Flame Spread/Smoke Developed Index (insulation) | 20 / 200 |

| ASTM E119 | Standard Test Methods for Fire Tests of Building Construction and Materials | Hourly Rating | 2 hrs assembly dependent |

| THERMAL | |||

| ASTM C518 | Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus | Thermal Resistance | 6.5 per inch of insulation |

| STRENGTH | |||

| ASTM D1621 | Standard Test Method for Compressive Properties of Rigid Cellular Plastics | Foam Compression Range | 30 psi |

| TAS 202-94 | Criteria for Testing Impact & Non-Impact Resistant Building Envelope Components Using Uniform Static Air Pressure | Deflection Properties | PASS |

| TAS 203-94 | Criteria for Testing Products Subject to Cyclic Wind Pressure Loading | Cyclic Deflection Properties | PASS |

| STRUCTURAL | |||

| ASTM E72 | Standard Test Methods of Conducting Strength Tests of Panels for Building Construction | Racking Resistance | PASS |

| ASTM E330 | Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference | Deflection Properties | Similar to TAS 202/203 - Data is in ESL-1306 |

| AIR | |||

| ASTM E283 | Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Skylights, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen | Air Infiltration at 75 Pa | 0.01 cfm/ft2 (0.1L/s/m2) |

| ASTM E283 | Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Skylights, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen | Air Infiltration at 300 Pa | 0.04 cfm/ft2 (0.2L/s/m2) |

| ASTM E2357 | Standard Test Method for Determining Air Leakage Rate of Air Barrier Assemblies | Air Leakage Resistance | PASS |

| WATER | |||

| ASTM E96 | Standard Test Methods for Gravimetric Determination of Water Vapor Transmission Rate of Materials | Procedure A Vapor Permeance (of 2" panel) | 0.2 Perms (grains/hr in Hg ft2) |

| ASTM E3312 | Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference | Water Penetration at 6.27 psf (300 Pa) | PASS |

| GENERAL | |||

| ASTM D1970 | Standard Specification for Self-Adhering Polymer Modified Bituminous Sheet Materials Used as Steep Roofing Underlayment for Ice Dam Protection | Fastener Sealability3 | PASS |

| ASTM C1338 | Standard Test Method for Determining Fungi Resistance of Insulation Materials and Facings | Mold and Mildew | PASS |

| ASTM D17614 | Standard Test Methods for Mechanical Fasteners in Wood and Wood-Based Materials | Fastener Shear in Sheathing Only | 519 lbs |

| ASTM D17614 | Standard Test Methods for Mechanical Fasteners in Wood and Wood-Based Materials | Fastener Pull Through | 505.2 lbs |

| ASTM D17614 | Standard Test Methods for Mechanical Fasteners in Wood and Wood-Based Materials | Fastener Withdrawal Capacity | 284 lbs |

1ArmorWall™ SP Plus FR SIS passes NFPA 285 attached directly to the stud framing allowing most cladding installed to its exterior as inclusive to the NFPA 285 approved assembly.

2Total test duration two continuous hours.

3ArmorWall™ SP Plus FR SIS is self-sealing around cladding attachment fasteners.

4Fastener data reflects attachment to the panel not attachment to structure.

Shear Properties

| Fastener Type | Min. Fastener Penetration into Framing | Panel Applied Direct to Framing (Fastener Spacing at Panel Edges in Inches) | Panel Applied Direct to Framing w/ 1/2" Gypsum on Opposite Face (Fastener Spacing at Panel Edges in Inches) | ||

|---|---|---|---|---|---|

| Shear (lbs/ft) w/ Framing of Douglas - Fir - Larch or Southern Pine with blocked perimeters | |||||

| 12" | 6" | 4" | 6" | ||

| #14-13 | 1" | 301 lbf (RNV) | 437.5 lbf (RNV) | 537.5 lbf (RNV) | 570 lbf (RNV) |

| #14-13 | 1" | 150 lbf (ASD) | 218.75 lbf (ASD) | 268.75 lbf (ASD) | 285 lbf (ASD) |

| #14-13 | 1" | 240 lbf (LFRD) | 350 lbf (LRFD) | 430 lbf (LRFD) | 456 lbf (LRFD) |

Deflection Properties

| Property | Test Method | Stud Thickness | Span | Results |

|---|---|---|---|---|

| L/240 | TAS 202-941 | 18 ga | 86" | +113/-95 psf (+5400/-4560 Pa) |

| L/240 | TAS 202-941 | 20 ga | 86" | +60/-40 psf (+2880/-1920 Pa) |

| L/360 | TAS 202-941 | 18 ga | 86" | +113/-75 psf (+5400/-3600 Pa) |

| L/360 | TAS 202-941 | 20 ga | 86" | +60/-25 psf (+2880/-1200 Pa) |

| TAS 203-942 | 18 ga | +113/-95 psf (+5400/-4560 Pa) | ||

| TAS 203-942 | 20 ga | +60/-40 psf (+2880/-1920 Pa) |

Code Compliance

<b>DuPont™ ArmorWall™ SP Plus Fire-Rated Structural Insulated Sheathing</b> complies with the following codes:

| Code | Description |

|---|---|

| US Product Listings & Verifications | ESL-1302 - Hourly Rated Walls<br>ESL-1306 - Deflection Properties - ASTM E330<br>ESL-1442 - Exterior Wall Fire Properties - NFPA 285<br>ESL-1543 - Cladding Fastener Spacing Tables |