DuPont™ ArmorWall™ System

<p>A 5-in-1 exterior wall solution</p>

DuPont™ ArmorWall™ System

<p>A 5-in-1 exterior wall solution</p>

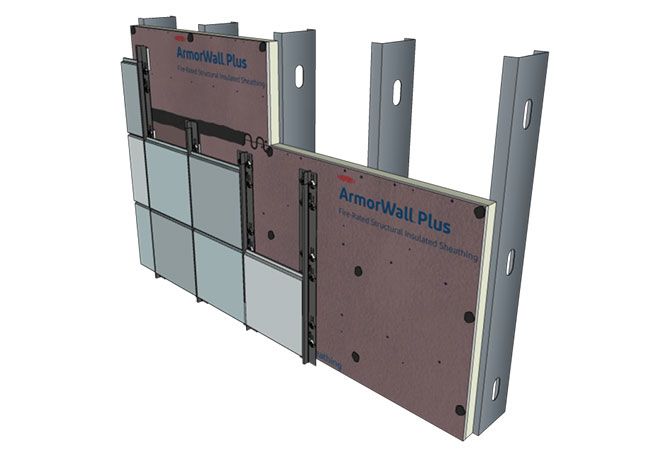

<p>The <b>DuPont™ ArmorWall™ System</b> is a premium, high-performance wall solution, incorporating five traditional building enclosure elements: </p>

<ul>

<li>Structural Sheathing for Direct Cladding Attachment </li>

<li>Fire-Resistance</li>

<li>Continuous Air Barrier</li>

<li>Water-Resistive Barrier</li>

<li>Ultra Low-GWP Continuous Insulation Layer</li>

</ul>

<p> </p>

<p>The <b>ArmorWall™ System enables multiple cladding attachment points virtually anywhere on the panel without requiring attachment back to the stud frame assembly or substrate</b>. Attaching essentially any cladding type, including brick and rainscreen assemblies, is no problem for ArmorWall™ thanks to its unique Magnesium Oxide (MgO) sheathing, providing exceptional strength and durability.</p>

Key Features & Benefits

- Proven performance for up to 2-hour fire-rated assemblies achievable and NFPA 285 compliance

- Third-party verified performance featured in multiple ICC-ES Listings

- Streamlines installation which can save time, labor and material costs

- Enables direct attachment of claddings without fastening back to studs

- Features a pre-applied air- and water-resistive barrier

- Insulation layer provides a high R-value of 6.5 per inch

- Patented Fusion Technology bonds the insulation to the MgO board, preventing voids seen in products that glue or laminate their materials together

- Certified by GreenCircle and eligible for LEED credits

- Enables compliance with ASHRAE 90.1 continuous insulation (CI) and thermal bridging energy code requirements

- Reduces onsite waste since weather-resistive barriers, insulation, and structural furring such as hat channels are no longer needed to be installed separately

DuPont™ ArmorWall™ System Products

Up to 2-hour fire-rated assemblies achievable to meet the needs of your project

Accessories Available to Complete the ArmorWall™ System

Advantages of the DuPont™ ArmorWall™ System