DuPont™ DuraGard™ WD Self-Adhered Flashing Tape

Self-adhered flashing tape for rough openings of windows and doors

DuPont™ DuraGard™ WD Self-Adhered Flashing Tape

Self-adhered flashing tape for rough openings of windows and doors

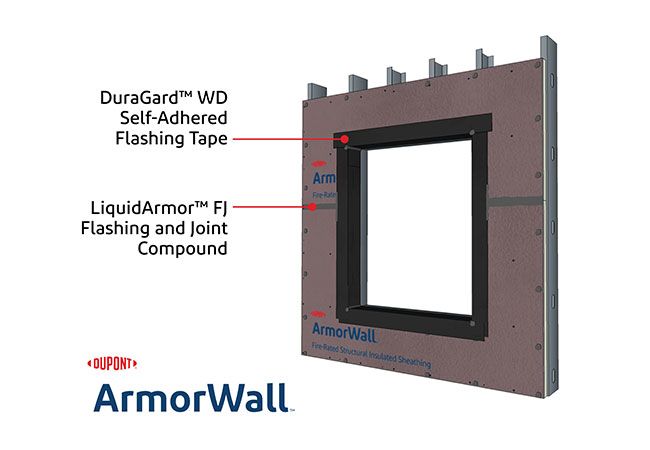

<br /><b>DuPont™ DuraGard™ WD Self-Adhered Flashing Tape </b>is a primerless window and door rough opening flashing which helps maintain the integrity of air and water-resistive barrier assemblies. By sealing and protecting vulnerable areas around openings, <b>DuraGard™ WD</b> can help improve the durability and energy efficiency of commercial buildings of all types.<br /><br /><b>DuraGard™ WD </b>is incorporated with an easy-to-remove, moisture-stable, split-release liner, allowing for precise alignment and installation onto exterior surfaces.<br /><br /><b>The Result</b>– A complete building envelope system when used with ArmorWall™ that helps keep moisture out and improve the energy efficiency of the building.

Features & Benefits

Specifications

Standard Sizes

| Unit | Width | Length | Units per Case | Cases per Pallet | Units per Pallet |

|---|---|---|---|---|---|

| Roll | 9 in. | 75 ft. | 4 | 60 | 240 |

| Roll | 10 in. | 75 ft. | 4 | 48 | 192 |

| Roll | 12 in. | 75 ft. | 4 | 36 | 144 |

Testing

<b>DuPont™ DuraGard™ WD</b> exhibits physical properties as indicated when tested as represented. Review all instructions and (Material) Safety Data Sheet ((M)SDS) before use. Please contact DuPont at 1-833-338-7668 when additional guidance is required for writing specifications that include this product.

| TEST METHOD | TEST TITLE | PROPERTY | RESULTS |

|---|---|---|---|

| STRENGTH | |||

| ASTM D882 | Standard Test Method for Tensile Properties of Thin Plastic Sheeting | Tensile Strength | 1300 psi |

| ASTM D882 | Standard Test Method for Tensile Properties of Thin Plastic Sheeting | Elongation | 800% to break |

| WATER | |||

| ASTM E96 | Standard Test Methods for Gravimetric Determination of Water Vapor Transmission Rate of Materials | Method A (Dry Cup) Water Vapor Transmission | 0.3 US Perms |

| ASTM E331 | Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference | Installed System Water Intrusion Testing(when installed with DuPont™ ArmorWall™ Plus) | No leaks @ 15 psf for 15 min |

| AIR | |||

| ASTM E2357 | Standard Test Method for Determining Air Leakage Rate of Air Barrier Assemblies | Installed System Air Intrusion Testing(when installed with DuPont™ ArmorWall™ Plus) | <0.04 cfm/sf at 75 Pa |

| GENERAL | |||

| ASTM D3652 | Standard Test Method for Thickness of Pressure-Sensitive Tapes | Thickness, Total | 15 mil |

| ASTM D5750 | Standard Guide for Width and Length of Pressure-Sensitive Tape | Width Tolerance | ± 1/16” |

| ASTM D5750 | Standard Guide for Width and Length of Pressure-Sensitive Tape | Length Tolerance | 0 to +6 |

| AAMA 711 | Specification for Self-Adhering Flashing Used for Installation of Exterior Wall Fenestration Products | Service Temperature Range | -40 °F – 240 °F (-40 °C – 115 °C) |

| AAMA 711 | Specification for Self-Adhering Flashing Used for Installation of Exterior Wall Fenestration Products | Material Standard for Self-Adhering Flashing Surrounding Exterior Wall Fenestration | Class A (no primer) and Level 3 Thermal Exposure (80°C/176°F for 7 days) |

| AAMA 711 | Specification for Self-Adhering Flashing Used for Installation of Exterior Wall Fenestration Products | Fastener Sealability (sec. 5.2) | PASS |

| ASTM G154 | Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Non-Metallic Materials | (per AAMA 711-20) UV Resistance | 180 days |

| AAMA 711 | Specification for Self-Adhering Flashing Used for Installation of Exterior Wall Fenestration Products | Installation Temperature Range | 0 °F (-18 °C) to 130 °F (54 °C) |