Highly efficient, low-energy pressure-driven separation

Nanofiltration (NF) is a membrane liquid-separation technology sharing many characteristics with reverse osmosis (RO). Unlike RO, which has high rejection of virtually all dissolved solutes, NF provides high rejection of multivalent ions, such as calcium, and low rejection of monovalent ions, such as chloride.

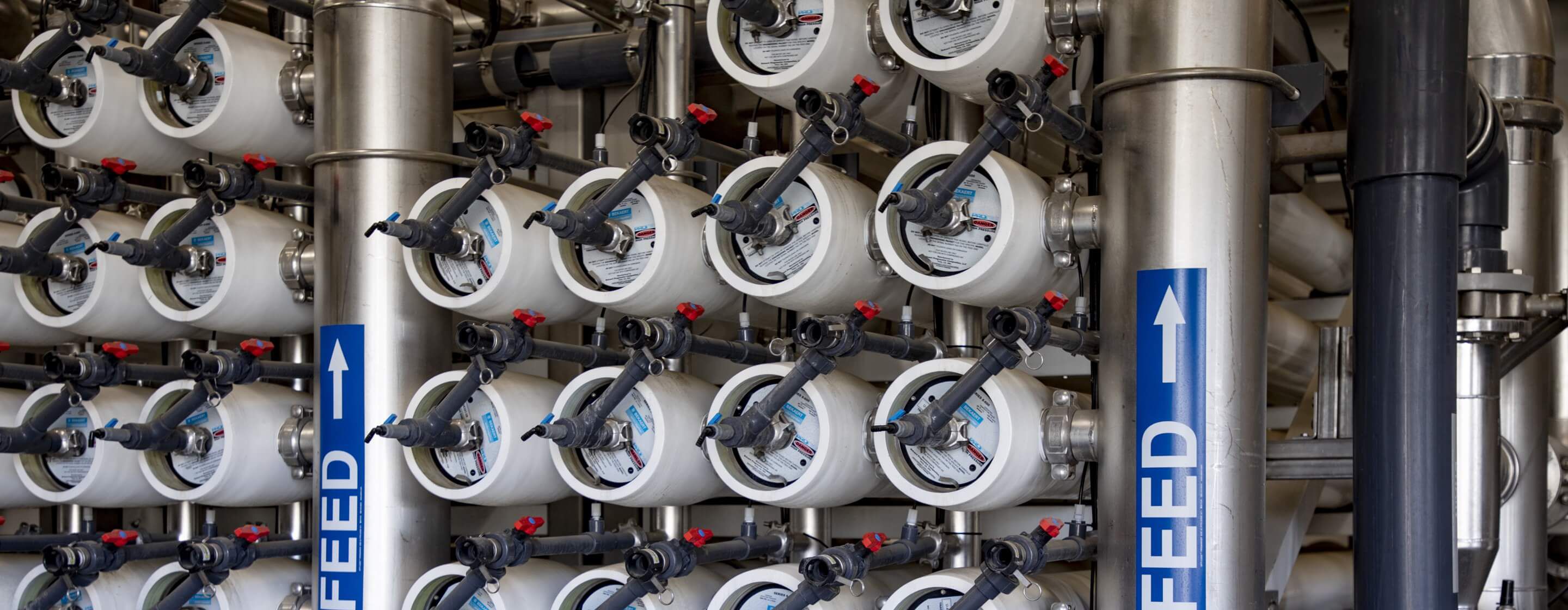

As the globally recognized leader in liquid-separation innovations and solutions, we help customers across industries and markets solve their toughest water-treatment challenges with our experience, expertise, and FilmTec™ portfolio of reverse osmosis and nanofiltration membrane technology.

A closer look

Between reverse osmosis and ultrafiltration

Nanofiltration refers to a specialty-membrane process that rejects dissolved solutes in the approximate size range of 1 nanometer (10 Angstroms) — hence the term “nanofiltration.”

With respect to the size and weight of solutes that nanofiltration membranes reject, NF operates in the realm between reverse osmosis (RO) and ultrafiltration (UF) : Organic molecules with molecular weights greater than 200 – 400 are rejected. Nanofiltration membranes can effectively reject, among other contaminants:

- Dissolved organics.

- Endotoxins/pyrogens.

- Insecticides/pesticides.

- Herbicides.

- Antibiotics.

- Nitrates.

- Sugars.

- Latex emulsions.

- Metal ions.

It also rejects certain soluble salts. Specifically, NF rejects dissolved salts in the range of 20 – 98 percent. Salts which have monovalent anions (e.g., sodium chloride or calcium chloride) have rejections of 20 – 80 percent, whereas salts with divalent anions (e.g., magnesium sulfate) have higher rejections of 90 – 98 percent. Transmembrane pressures are typically 50 – 225 psi (3.5 – 16 bar).

The ideal nanofiltration membrane has a very high water permeability, but the ideal permeability of solutes might be near zero or some higher value, depending on the solute and application. For example, an application may require near-zero permeability for pesticides and 50 percent permeability for calcium ions.

Typical applications of nanofiltration membrane systems include:

- The removal of color and total organic carbon (TOC) from surface water.

- The removal of hardness or radium from well water.

- The overall reduction of total dissolved solids (TDS).

- The separation of organic from inorganic matter in specialty food* and wastewater applications.

Pressure and crossflow

Like reverse osmosis membranes, nanofiltration membranes are used in separation systems employing applied pressure to effectively overcome the system’s osmotic pressure, reversing the flow of a solvent across a semipermeable membrane from an area of higher solute concentration to an area of lower concentration. This “reversed” flow, and the degree of permeability of the nanofiltration membrane, result in solutes too large to pass through the membrane remaining on the higher-concentration side of the membrane, while purer water that contains desired or acceptable solutes flows through.

Nanofiltration membranes are similar to RO membranes in another way: They are used in crossflow configurations. Crossflow helps to minimize fouling, or the accumulation of solutes that cannot pass through the semipermeable membrane against the membrane. Very simply stated, in crossflow a pressurized flow of feedwater forces lower-concentration water through the NF membrane, while the now-isolated flow of higher-concentration water moves across the surface of the membrane, carrying away the rejected salts and other impurities. The purified water is called the permeate, while the higher-concentration water is called the concentrate or reject.

Influencing factors

The key performance parameters of a nanofiltration membrane separation process are permeate flux and salt rejection. Under specific reference conditions, flux (the rate of permeate transported per unit of membrane area) and rejection are predictable, intrinsic properties of membrane performance. The flux and rejection of a membrane system are mainly influenced by variable parameters, including:

- Pressure: With increasing effective feed pressure, the permeate TDS will decrease while the permeate flux will increase.

- Temperature: If the temperature increases while all other parameters (pressure, recovery, and feedwater salt concentration) are constant, the permeate flux and the salt passage will increase.

- Recovery: Recovery is the ratio of permeate flow to feed flow. In the case of increasing recovery, the permeate flux will decrease and stop if the salt concentration reaches a value where the osmotic pressure of the concentrate is as high as the applied feed pressure. The salt rejection will decrease with increasing recovery.

- Feedwater salt concentration: With increasing feedwater salt concentration, the permeate flux will decrease while salt passage will increase.

Other factors that may affect the performance of an NF system include:

- Maintenance and operation of the plant.

- Pretreatment design.

-

What Is NF?

Between reverse osmosis and ultrafiltration

Nanofiltration refers to a specialty-membrane process that rejects dissolved solutes in the approximate size range of 1 nanometer (10 Angstroms) — hence the term “nanofiltration.”

With respect to the size and weight of solutes that nanofiltration membranes reject, NF operates in the realm between reverse osmosis (RO) and ultrafiltration (UF) : Organic molecules with molecular weights greater than 200 – 400 are rejected. Nanofiltration membranes can effectively reject, among other contaminants:

- Dissolved organics.

- Endotoxins/pyrogens.

- Insecticides/pesticides.

- Herbicides.

- Antibiotics.

- Nitrates.

- Sugars.

- Latex emulsions.

- Metal ions.

It also rejects certain soluble salts. Specifically, NF rejects dissolved salts in the range of 20 – 98 percent. Salts which have monovalent anions (e.g., sodium chloride or calcium chloride) have rejections of 20 – 80 percent, whereas salts with divalent anions (e.g., magnesium sulfate) have higher rejections of 90 – 98 percent. Transmembrane pressures are typically 50 – 225 psi (3.5 – 16 bar).The ideal nanofiltration membrane has a very high water permeability, but the ideal permeability of solutes might be near zero or some higher value, depending on the solute and application. For example, an application may require near-zero permeability for pesticides and 50 percent permeability for calcium ions.

Typical applications of nanofiltration membrane systems include:

- The removal of color and total organic carbon (TOC) from surface water.

- The removal of hardness or radium from well water.

- The overall reduction of total dissolved solids (TDS).

- The separation of organic from inorganic matter in specialty food* and wastewater applications.

-

NF Technology Basics

Pressure and crossflow

Like reverse osmosis membranes, nanofiltration membranes are used in separation systems employing applied pressure to effectively overcome the system’s osmotic pressure, reversing the flow of a solvent across a semipermeable membrane from an area of higher solute concentration to an area of lower concentration. This “reversed” flow, and the degree of permeability of the nanofiltration membrane, result in solutes too large to pass through the membrane remaining on the higher-concentration side of the membrane, while purer water that contains desired or acceptable solutes flows through.

Nanofiltration membranes are similar to RO membranes in another way: They are used in crossflow configurations. Crossflow helps to minimize fouling, or the accumulation of solutes that cannot pass through the semipermeable membrane against the membrane. Very simply stated, in crossflow a pressurized flow of feedwater forces lower-concentration water through the NF membrane, while the now-isolated flow of higher-concentration water moves across the surface of the membrane, carrying away the rejected salts and other impurities. The purified water is called the permeate, while the higher-concentration water is called the concentrate or reject.

-

NF Membrane Performance

Influencing factors

The key performance parameters of a nanofiltration membrane separation process are permeate flux and salt rejection. Under specific reference conditions, flux (the rate of permeate transported per unit of membrane area) and rejection are predictable, intrinsic properties of membrane performance. The flux and rejection of a membrane system are mainly influenced by variable parameters, including:

- Pressure: With increasing effective feed pressure, the permeate TDS will decrease while the permeate flux will increase.

- Temperature: If the temperature increases while all other parameters (pressure, recovery, and feedwater salt concentration) are constant, the permeate flux and the salt passage will increase.

- Recovery: Recovery is the ratio of permeate flow to feed flow. In the case of increasing recovery, the permeate flux will decrease and stop if the salt concentration reaches a value where the osmotic pressure of the concentrate is as high as the applied feed pressure. The salt rejection will decrease with increasing recovery.

- Feedwater salt concentration: With increasing feedwater salt concentration, the permeate flux will decrease while salt passage will increase.

Other factors that may affect the performance of an NF system include:- Maintenance and operation of the plant.

- Pretreatment design.

Our approach to nanofiltration

Our nanofiltration membranes are part of our industry-leading, globally recognized FilmTec™ portfolio . FilmTec™ thin film composite membranes consist of three layers, each designed to specific requirements.The layers are:

- A polyester support web.

- A microporous polysulfone interlayer.

- An ultrathin polyamide barrier layer on the top surface.

FilmTec™ NF membranes give excellent performance for a wide variety of applications in terms of flux, salt and organics rejection, and fouling resistance. FilmTec™ elements can operate over a pH range of 2 – 11, are resistant to compaction, and are suitable for temperatures up to 45°C. They can be effectively cleaned at pH 1 and pH 13, depending on temperature. (Please consult product data sheets for pH limits for specific NF membranes.)

Durable and easy to clean, they exhibit stable performance over several years, even under harsh operating conditions.

FilmTec™ NF elements can be used to purify public drinking water in areas where the high level of sodium rejection possible with reverse osmosis (RO) membranes is not needed, but where other salts such as calcium and magnesium must be reduced. Compared to lime softening and sodium chloride (NaCL) zeolite softening technologies, nanofiltration membrane softening is a less-expensive alternative. The FilmTec™ NF270 nanofiltration membrane, for example, offers low salt rejection, low energy consumption, and stable performance after repetitive cleaning. These features make it a prime choice for contaminated surface waters.

Find nanofiltration products

View a list of our industry-leading nanofiltration products.

Related industries

Our technologies provide premium solutions for a broad range of industries. Learn more about the industries that depend on nanofiltration technology.

We help offices, schools, hospitals, hotels, and universities enhance their facilities with our water-treatment solutions.

We help everyone’s favorite foods and beverages taste better with advanced separations of sugars, dairy streams, and other nutritional ingredients.

Our technologies and solutions are designed to help you overcome water challenges to produce your desired quantity and quality of industrial utility water.

We help ensure a steady flow of clean, safe drinking water into local communities with our water-treatment solutions

We help energy companies improve operational efficiency with specialized water treatment and wastewater reuse.

We enable the smooth and safe operation of power plants through innovative water-treatment and wastewater reuse.

Related resources

Notes

*Nanofiltration membranes have received FDA clearance for use in processing liquid foods and in purifying water for food applications. This clearance is published in the Code of Federal Regulations under Title 21, Section 177.2550, Reverse Osmosis Membranes. All FilmTec™ nanofiltration membranes comply with this regulation.

See what’s possible

Ask us how nanofiltration can help you improve the performance of your liquid-separation processes.