Broad Bake Adhesives Supporting Sustainable Manufacturing

Article

In EVs, higher-energy-density batteries create vehicle design challenges with respect to safety and require special reinforcement structures in the body - especially the sill area. As a result of the higher thermal mass in the sill and the thermal insulation effect of its nested structure, temperatures during the oven process are drastically reduced.

Shorter oven cycle times enable significant energy savings

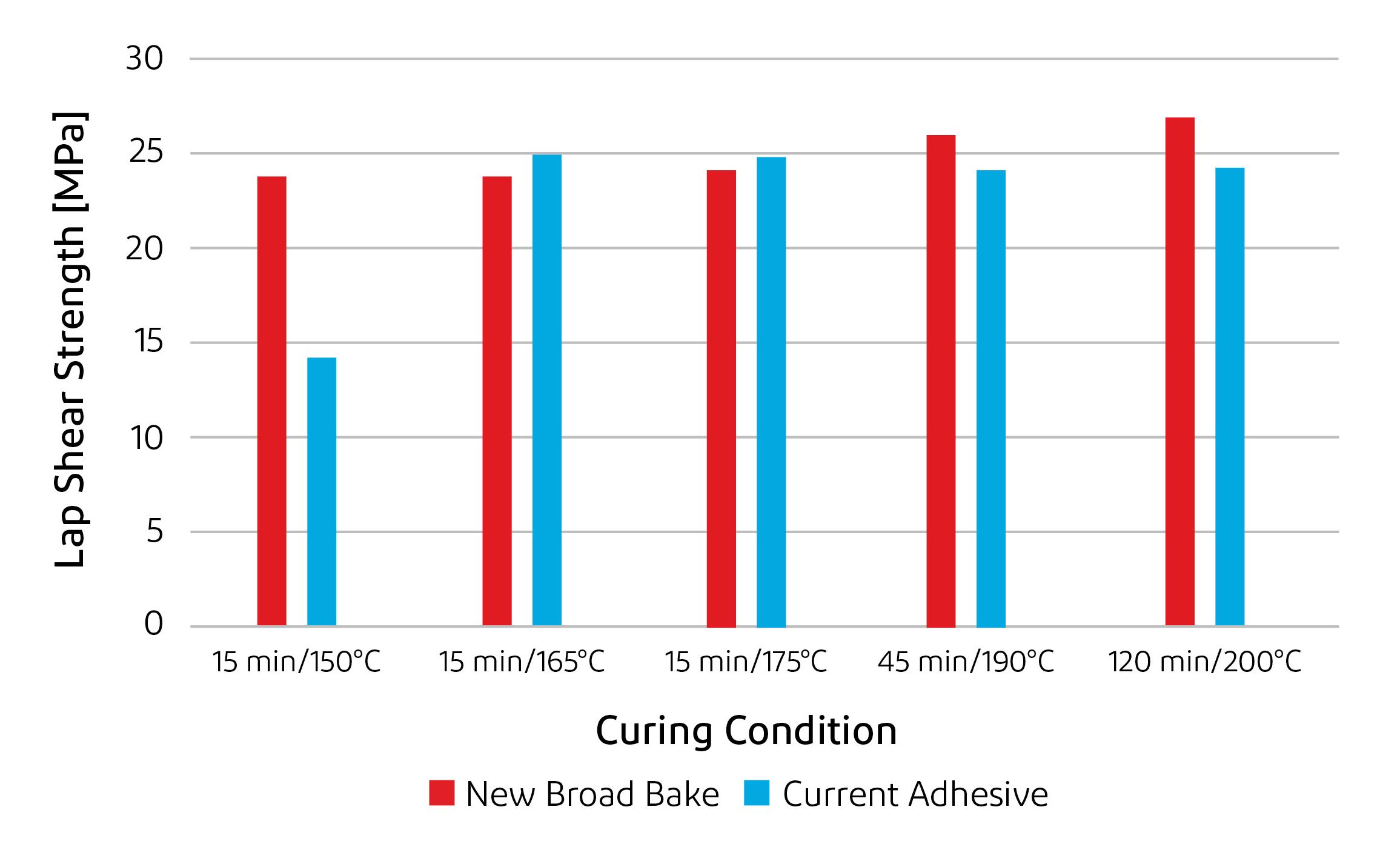

BETAMATE™ broad bake adhesives allow a reduction of the e-coat oven temperature by 25°C enabling significant energy savings, while durably bonding the high mass underbody of EV body structures in the body shop. They also cure can cure at lower temperatures than current state-of-the-art adhesives, enabling shorter oven cycle times.

BETAMATE™ broad bake adhesives exhibit lap shear strength within the 150°C at 15-minute requirement

Long-lasting quality and shelf life

In addition, BETAMATE™ broad bake adhesives provide excellent corrosion resistance, enhance passenger safety, deliver high elastic modulus and tensile strength, maintaining the quality of the bond over the vehicle’s projected lifetime and with a shelf life of at least six months.