Permeation matters.

When it comes to chemical protection, permeation is the only test that represents a fabric's true chemical resistance.

That's why DuPont publishes permeation data. In fact, we've published more than 2,400 permeation results for our Tychem® garment fabrics.

Permeation is the movement of liquid or gas through a fabric at the molecular level.

Not every manufacturer gives you the full picture.

Not all garment manufacturers publish permeation data. For example, Lakeland Industries only publishes penetration data for its chemical resistant/secondary flame-resistant garment, Pyrolon® CRFR.

They provide no information about how the garment performs in permeation tests.

DuPont, on the other hand, publishes permeation data for our chemical resistant/secondary flame-resistant garment fabric, Tychem® 2000 SFR.

Bottom line?

If chemical protection is your need, permeation is your test. Make sure you know the type of test that was conducted on your garments.

Permeation Data of Fabrics

Lakeland

View Data

Dupont Data

Comparisons can be confusing.

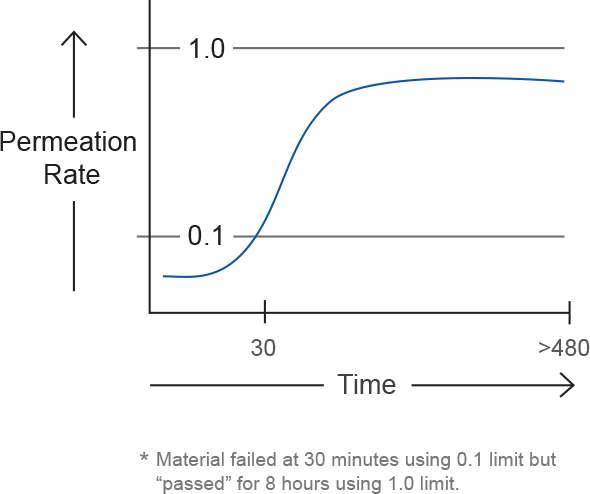

When you're considering how long garments can be worn before chemical breakthrough, it's important to understand the type of permeation testing that has been performed on them.

ASTM F739 specifies that results should be recorded at a normalized breakthrough time (NBT) of 0.1 µg/cm2/min. DuPont tests all Tychem® fabrics using this method. ASTM F739 is the standard test used in North America. Another commonly used permeation test uses an NBT of 1.0 µg/cm2/min., a rate used in Europe per EN ISO 6529.

The ASTM F739 method, the method DuPont sites, is the more stringent and sensitive test for chemical permeation, because it defines breakthrough at a 10x lower threshold.

Bottom line?

When deciding on protective garments, make sure you're comparing fabrics that are tested at the same permeation rate limits.

- Seek data for the specific chemicals you work with.

- Look at the permeation test limit method used (1.0 µg/cm2/min or 0.1 µg/cm2/min) in addition to NBT.

Why?

The decision could possibly mean the difference between protection and exposure. Because DuPont uses the more stringent method for all testing, the selection process is easier.

Which certification matters?

There are many standards out there that measure garment performance. CE certification is a measure of performance required by the European Union. The CE marking means that chemical protective clothing meets certain minimum requirements, but it doesn't indicate superior performance versus non-CE certified garments.

Bottom line?

Garment protection comes down to understanding the specific hazards your workers face and knowing how their garments will perform against those hazards. DuPont™ SafeSPEC™ can help.

Note: If CE Certification is required by your organization, DuPont offers CE certified apparel as well.

CE Certification doesn't apply to the U.S. market.

Not everything is what it "seams"

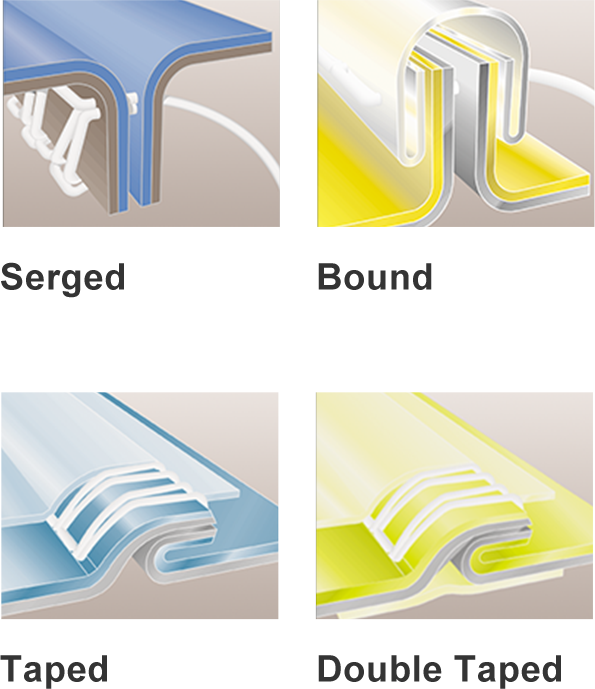

Seams make a big difference in the overall protection a garment provides.

Some competitors may compare performance of a taped or bound seam garment to that of a serged seam garment.

That's not an honest, "apples-to-apples" comparison. Performance comparisons should always be made between garments with similar seam constructions.

DuPont offers garments with different types of seams: serged, bound, and taped. When deciding which garment to purchase, make sure you compare garments with the same type of seams, and select a seam type that meets your hazard needs.

Different seams offer different levels of protection. It's misleading to make comparisons between garments with different kinds of seams.

Focus on the fabric.

When you're reviewing competitors' claims of how their fabrics perform versus Tyvek®, pay attention to the fabric type.

For example, the fabrics Lakeland and Kimberly-Clark compare to Tyvek® typically are made with either microporous film (MPF) or spunbond-meltblown-spunbond (SMS) fabric—neither of which has the unique properties of Tyvek®.

Engineered using proprietary, flashspun polyethylene technology, garments made with Tyvek® fabric provide many advantages versus the competition, including superior barrier protection after abrasion, durability and comfort.

Bottom line?

There are many SMS and microporous film-based personal protective equipment (PPE) fabric options, but there's only one Tyvek®.

Not all "white suits" have the built-in protection of Tyvek®.

Performance that speaks for itself.

DuPont is the trusted leader in PPE garment technology for good reason.

Every protective garment we make is the result of years of product development and testing.

We offer a full range of suits that are matched to nearly every on-the-job hazard, from dirt and grit to some of the most toxic compounds on earth.

We don't make confusing comparisons or offer incomplete data. Our test results and garment performance speak for themselves.

Bottom line?

There's no substitute for DuPont protection.

Get the facts.

Go right to the source with DuPont™ SafeSPEC™. Our online selector tool makes it easy to find dependable, rigorously tested protective garments that meet your hazard needs.