Turbochargers and EGR

Reliable Vespel® components resist the high temperatures of turbochargers and EGR systems and help reduce emissions

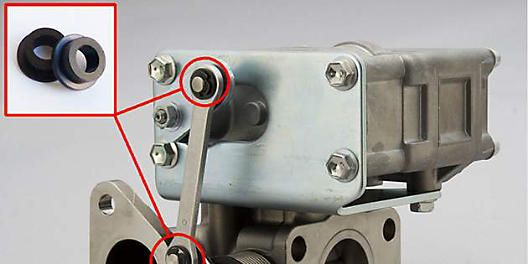

The ability of DuPont™ Vespel® materials to resist heat and provide thermal insulation allows engineers more options when designing automotive turbochargers and EGR (exhaust gas recirculation) systems.

One way to increase fuel efficiency and reduce emissions is through the use of turbochargers and EGR technology. However, in a turbocharged environment, components must be able to withstand extremely high temperatures. Vespel® bushings and washers do not melt even under the most demanding engine conditions, including temperatures up to 300°C (and even higher short term).

Even in EGR environments of oil pitch from exhaust gas and carbon particles, Vespel® offers high performance with low friction and low wear.

Vespel® allows engine designers more flexibility because it provides:

• Low wear and low friction

• Low thermal expansion

• Improved NVH performance versus metal

• Impact and creep resistance

• Exceptional dimensional stability

• Chemical resistance

• Heat insulation between turbo body and actuator

Ideas & innovations

Powered by a broad product portfolio and state-of-the-art expertise, we help our partners meet the critical industry demands of the electrical and electronics market.

Featured resources

Literature

Vespel® Parts for E-Mobility Applications

Vespel® Parts for Internal Combustion Engine Applications

DuPont™ Vespel Parts and Shapes

DuPont™ Vespel® S Line Design Handbook

Case Studies

Vespel® CP-0664 Adds Life to V-Grooves

Vespel® Line Shaft Bearings for Pumps

Vespel® Brings High-Temperature Performance to Aircraft Bushings and Washers

Articles

Vespel® Supporting Sustainable Mobility

Vespel® Boost Efficiency & Reduce Fuel Consumption

Vespel® Materials for Turbochargers

Vespel® Powering Sustainable Mobility

Additional links