Career opportunities

Join our dedicated team focused on delivering results that matter and delivering innovations that make a difference in the lives of people everywhere.

We're focused on delivering results that matter to our stakeholders and innovating solutions that make a difference in the lives of people everywhere.

Innovation is at the heart of all we do. We deliver high-value solutions through strategic R&D investment, prioritization of innovation challenges and smart resource allocation – driving growth, speed to market and measurable impact for our customers.

"Innovation is at the heart of DuPont. And we're proud that more than 75% of our innovation portfolio is sustainably advantaged with a strong focus on climate and safe and sustainable-by-design product launches."

Marty DeGroot, DuPont Chief Technology Officer

Technical & Application Centers

Our network of global Technical and Application Centers advance program milestones and problem-solving between customers and DuPont scientists and engineers. Our flagship Innovation Centers in Wilmington, DE (U.S.) and Shanghai, China tackle industry challenges with collaboration across value chains, customers, partners, academics, government and more.

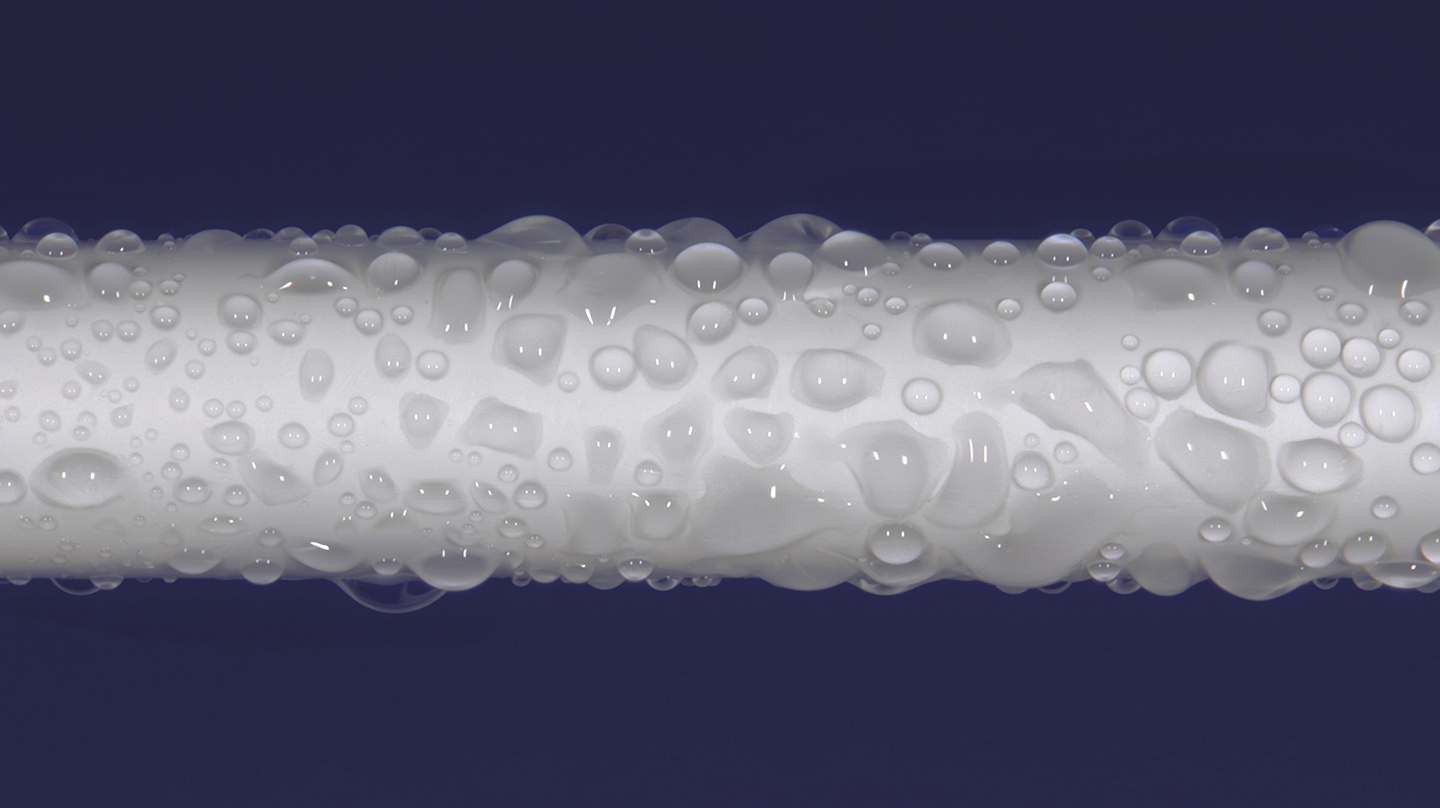

DuPont Water Solutions innovates advanced membrane and ion exchange resin technology solutions to address water, energy, and wellness challenges. Our broad portfolio tackles even the hardest-to-treat water and process challenges with fit-for-purpose solutions to meet our customers’ unique challenges.

Our innovations in healthcare are enhancing pharmaceutical production, improving medical device performance, enabling transdermal drug delivery, and protecting both equipment and people through Tyvek® garments and Tyvek® healthcare packaging.

Deep understanding and capabilities in material science enable our businesses to develop solutions for challenges in industrial automation, wide-spread electrification, vehicle light-weighing and digital printing and packaging.

Advancing sustainability in the built environment requires innovative construction solutions that help drive the whole life carbon of buildings to net-zero, enhance material circularity, and promote the utilization of safer chemistries.

Discover the advantages of licensing technology from DuPont.

We’ve worked with thousands of licensees worldwide to help find solutions to their real-world challenges and bring value to their businesses.