-

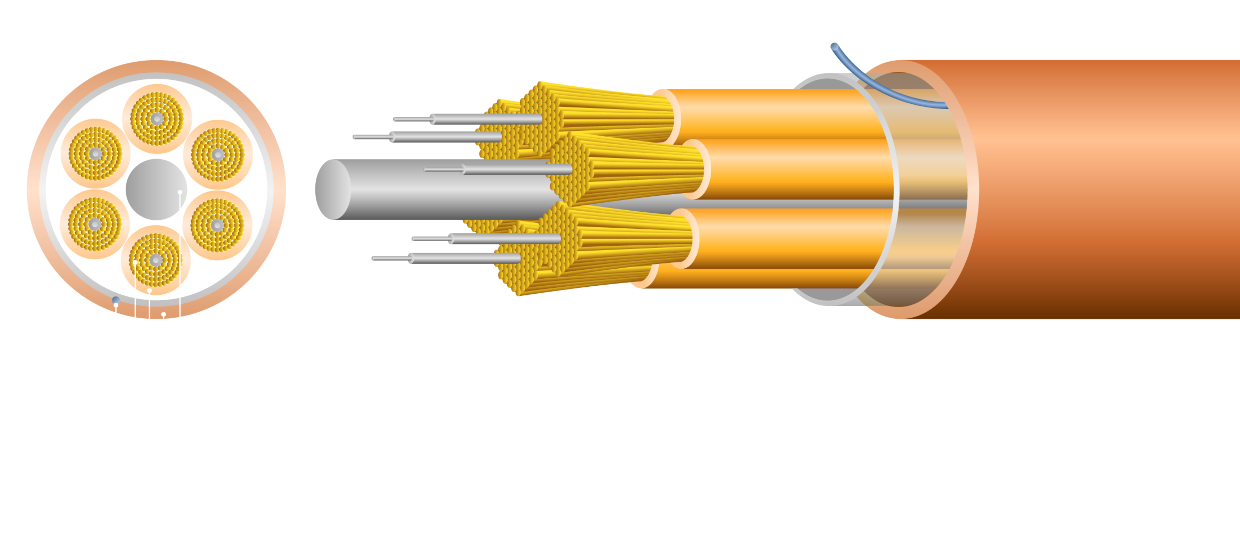

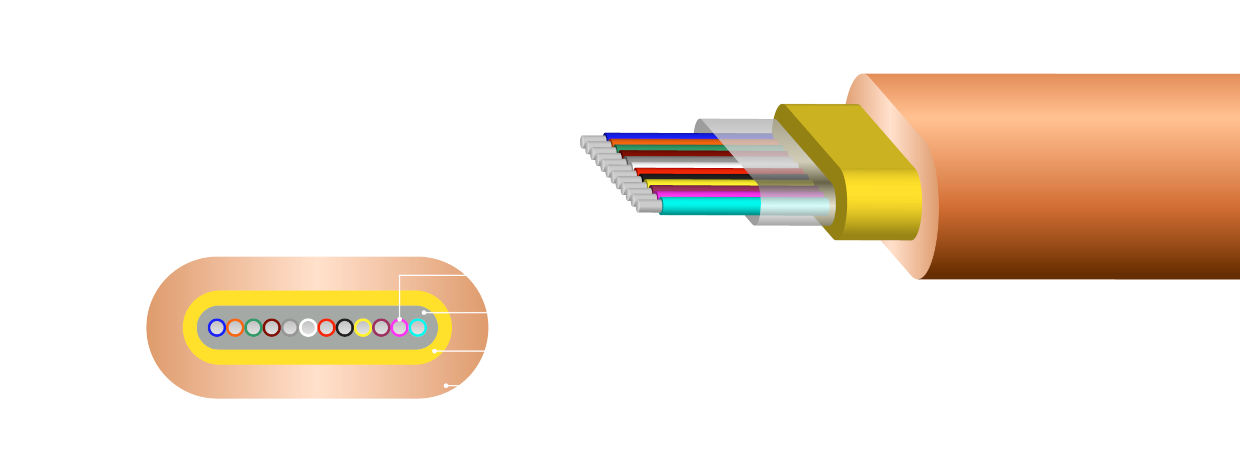

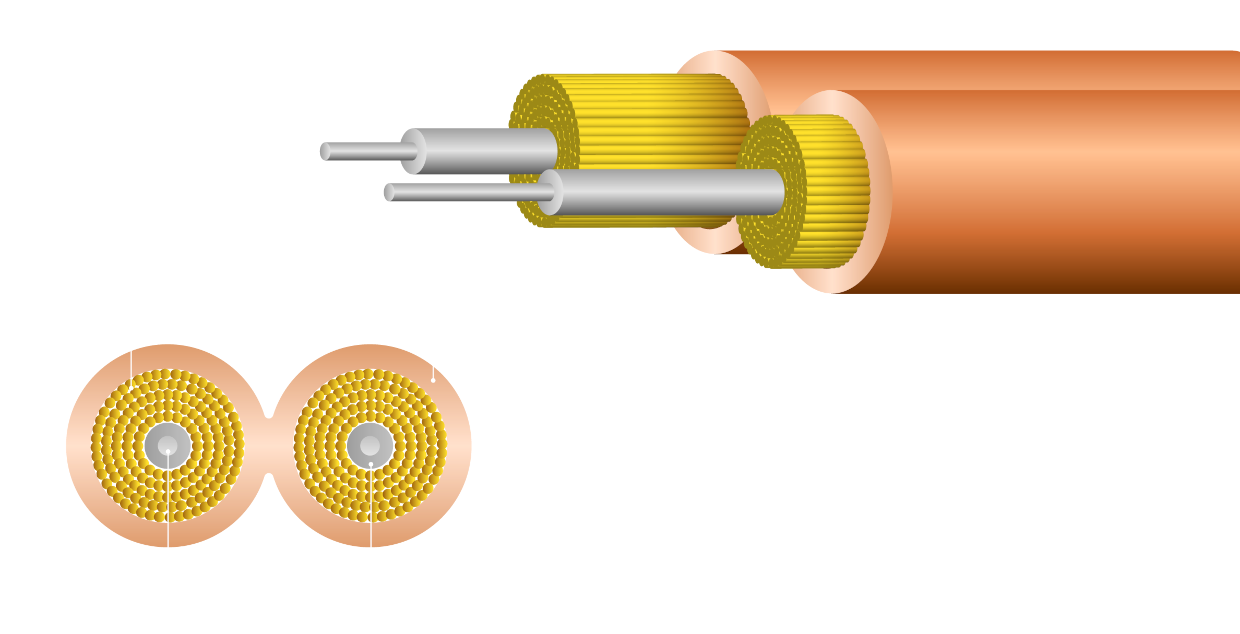

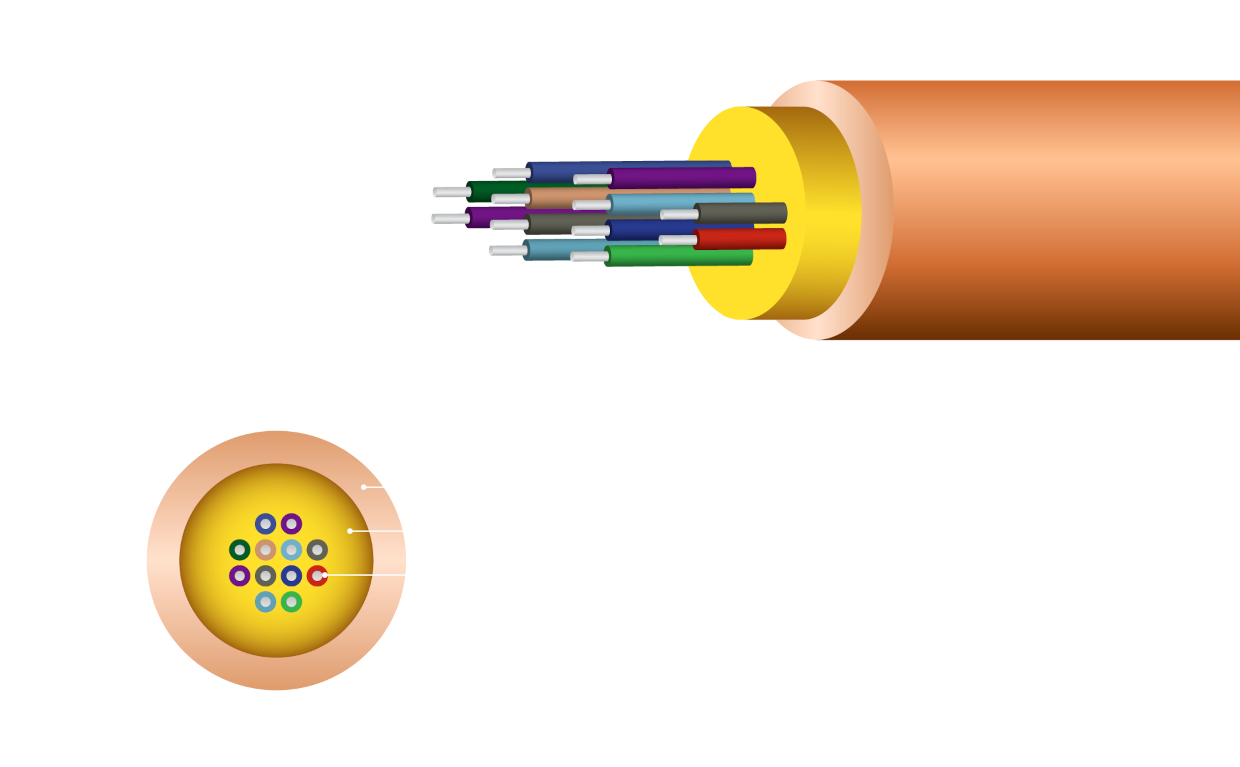

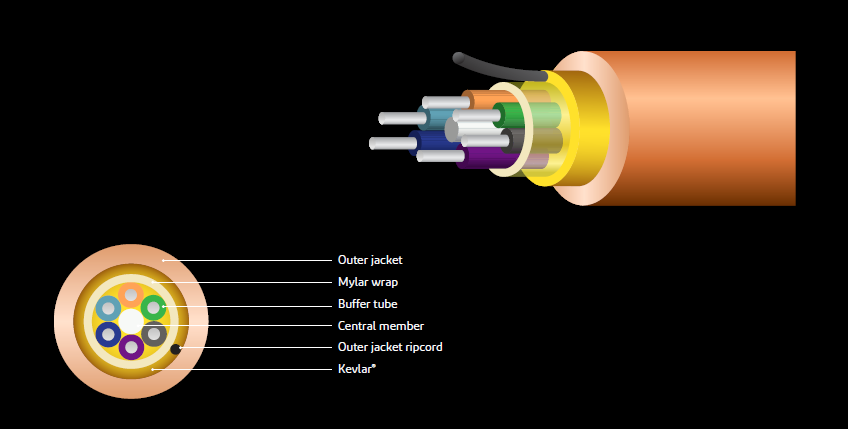

Indoor Fiber Cables

-

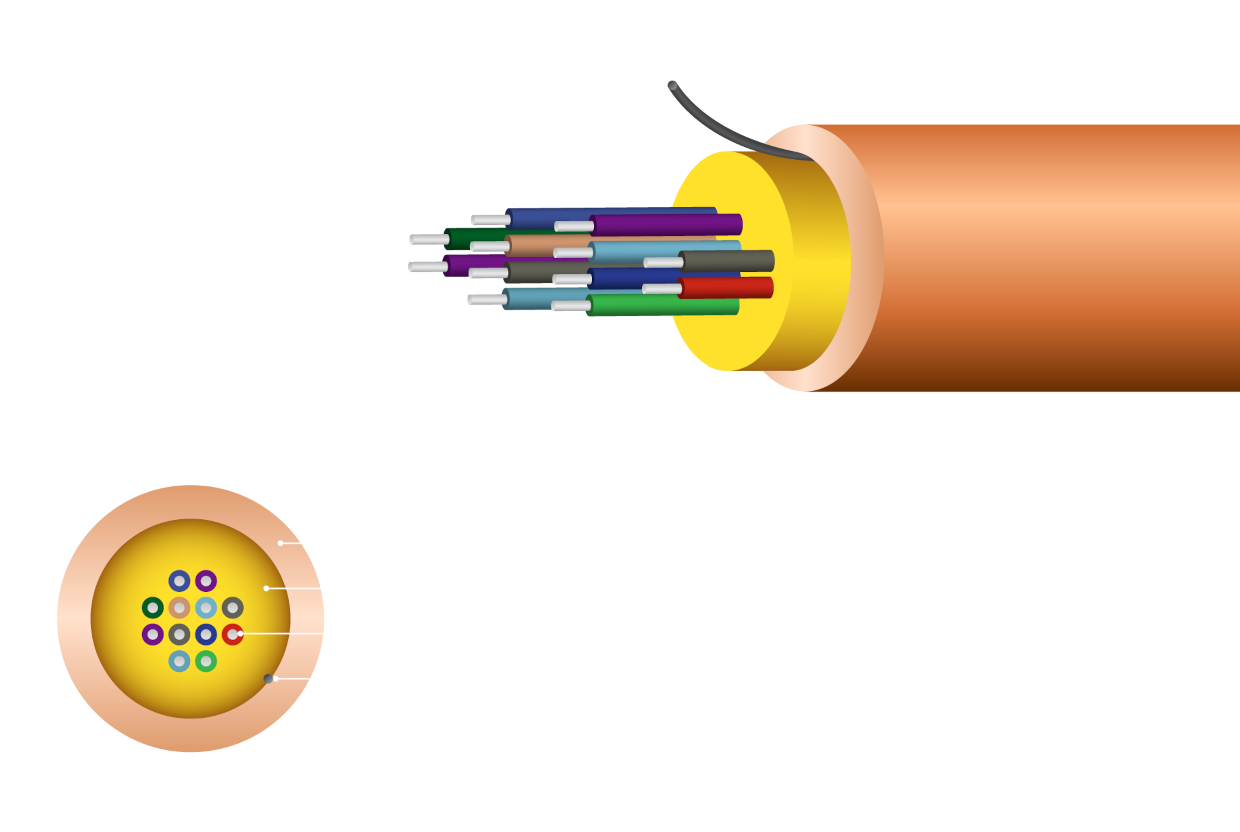

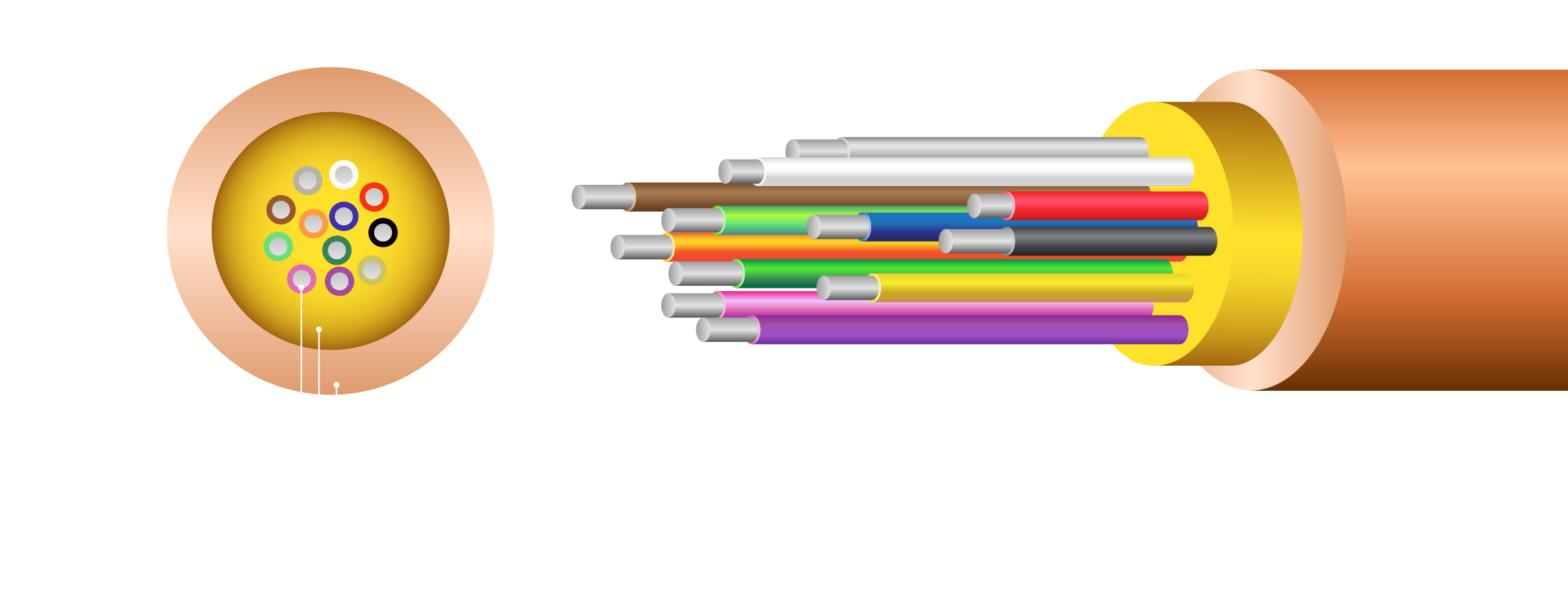

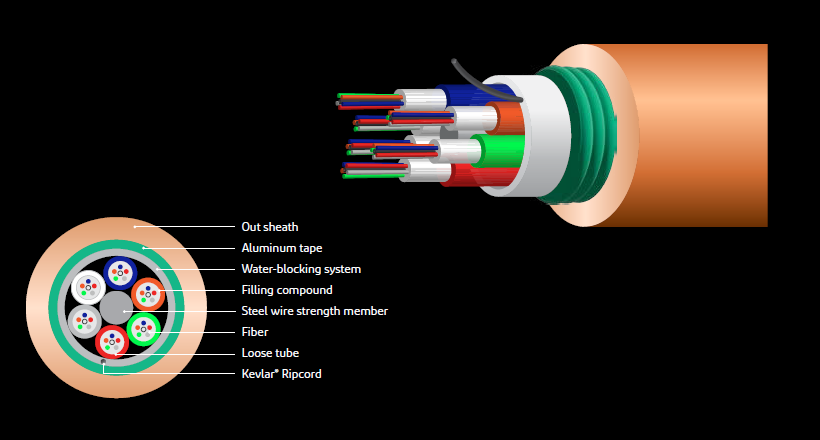

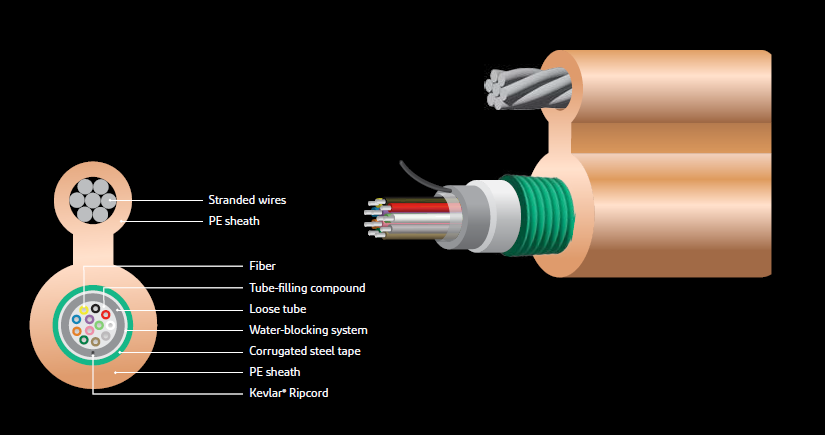

Outdoor Fiber Cables

DuPont™ Kevlar® is not just enhancing the present—it’s enabling a stronger, more resilient future for networks that power global communications. With its exceptional strength-to-weight ratio, Kevlar® helps provide the backbone for safeguarding optical fibers to ensure optimal performance.

With built-in performance that’s designed for a digital world, Kevlar® helps you ensure connectivity in any condition.

REDEFINE WHAT’S POSSIBLE WITH DUPONT™ KEVLAR®

Kevlar® offers the strength, flexibility and durability fiber optic cables need to ensure the performance and protection they demand. Its lightweight, heat-resistant and non-flammable properties make it essential for maintaining the integrity of fiber optic cables in harsh conditions, offering reliable and efficient signal transmission over long distances.

Thin and lightweight

Unmatched strength

Heat resistance

Highly flexible

Chemical / Corrosion resistance

Durability

DuPont™ Kevlar® is used as a key strength member for a range of indoor applications—helping to enable cables to be pulled, bent and easily installed while keeping their critical optical fibers protected.

Indoor Aplications

DuPont™ Kevlar® offers the tensile strength, protection against environmental elements and flexibility to withstand harsh conditions and maintain performance across long distances.

Outdoor Aplications

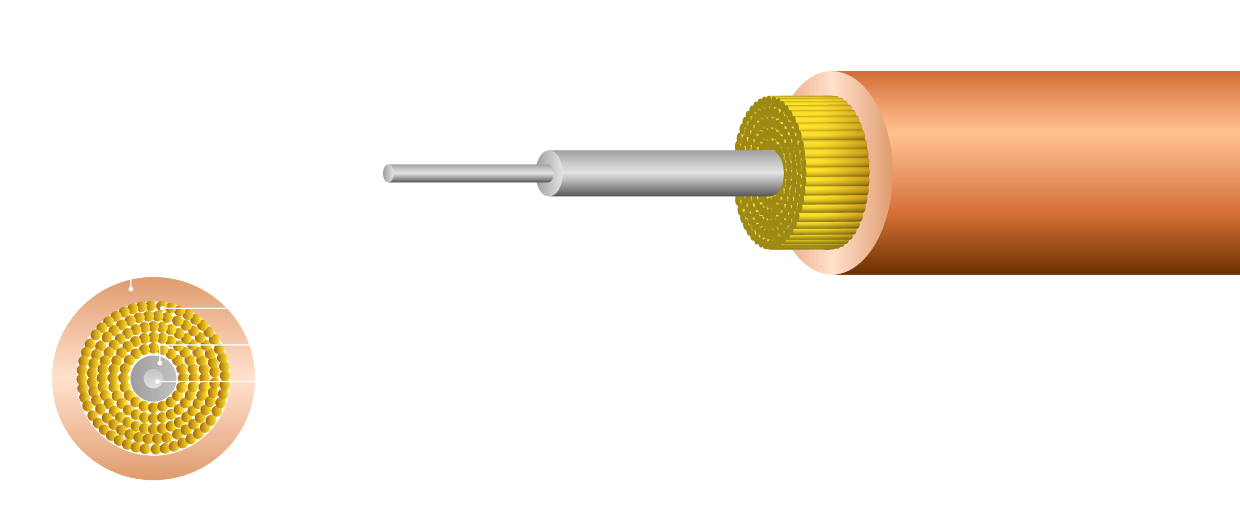

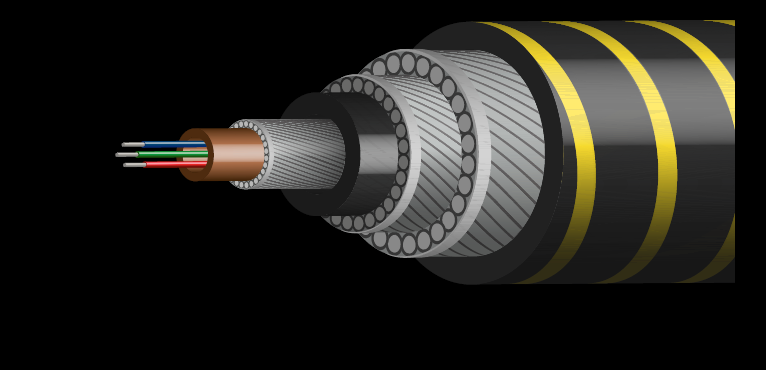

Submarine cable

Kevlar® delivers the high tensile strength and durability to withstand extreme underwater pressures, abrasion and environmental stress over long distances.

Submarine fiber cables

Used in fresh or saltwater, featuring complex structures and armors to protect against damage from fishing trawlers and boat anchors, especially in long-distance applications.