-

Offshore

-

Onshore

In oil and gas extraction and transportation, every component counts. Whether it’s onshore or offshore, DuPont™ Kevlar® helps enable the strength, durability, flexibility and chemical resistance to overcome the extreme demands facing the Oil & Gas industry.

With solutions that can go beyond conventional limits, solutions reinforced with Kevlar® have been trusted by industry’s infrastructure for over three decades.

Redefine What’s Possible With DUPONT™ KEVLAR®

Kevlar® helps manufacturers overcome most demanding challenges to offer optimal, reliable and safer operations.

Thin and lightweight

High strength

Heat resistance

Highly flexible and low bending radius

Chemical/corrosion resistance

Durability

Offshore Application

Umbilicals

Kevlar® helps elevate strength and flexibility while reducing weight in umbilicals for reliable performance that can withstand harsh chemicals and working conditions.

Risers

The high tensile strength and corrosion resistance of Kevlar® can enable risers to endure the most extreme offshore conditions and dynamic loads.

Floating/Offloading hoses

Through its lightweight and durable properties, Kevlar® helps make floating hoses lighter while maintaining a low bending radius.

Mooring lines

The low creep, high modules and exceptional tensile strength of Kevlar® helps preserve critical stability under stress for offshore platforms to the seabed.

Onshore Application

Reinforced thermoplastic pipes (RTP)

Designed to withstand high pressures, Kevlar® helps provide unmatched durability, corrosion resistance and flexibility for increased spool lengths, easier installation and lower OPEX.

Rehabilitation pipes

Kevlar® helps provide the strength, flexibility and durability for long-term performance while also enabling easier installation.

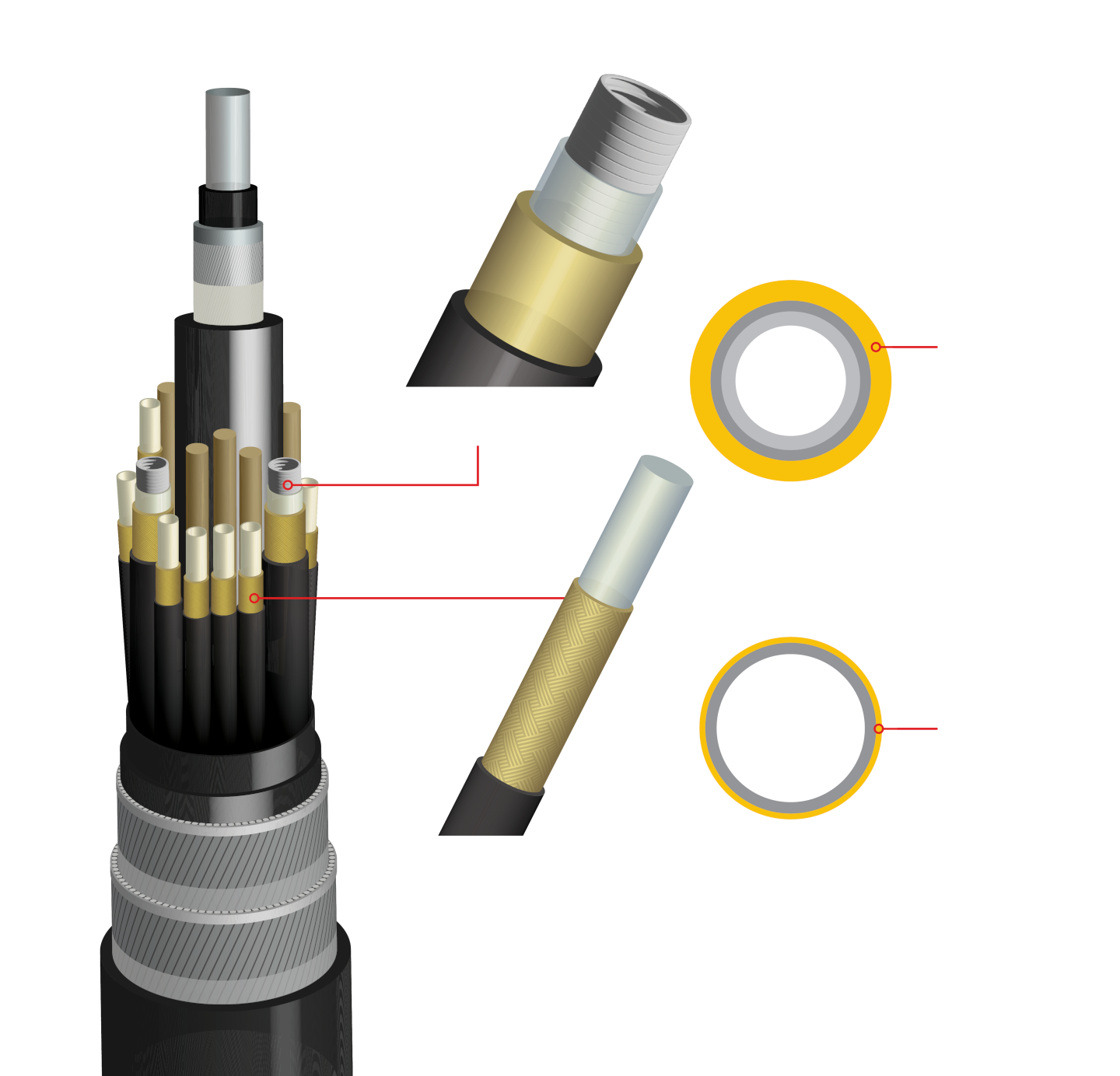

Umbilicals Reinforced With Dupont™ KEVLAR®

From high collapse-resistant hoses to hydraulic hoses, Kevlar® helps enable the performance that thermoplastic umbilicals demand to maintain essential hydraulic, chemical and electrical connections with critical subsea equipment.

MORE PERFORMANCE. LESS WEIGHT.

Compared to steel umbilical tubes, thermoplastic umbilicals reinforced with DuPont™ Kevlar® offer a lighter, stronger, more durable and flexible solution than steel and can overcome the challenges of evolving offshore operations.

• High-pressure reliability

• Lower weight

• More flexibility

• High-pressure reliability

• Lower weight

• More flexibility

• More durability

• High-pressure reliability

• Faster lead time

Flexible Risers Reinforced With Dupont™ KEVLAR®

When used in anti-bird cage (ABC) tapes, the high tensile strength, corrosion and fatigue resistance of Kevlar® helps maintain the performance and integrity of flexible risers. Its ability to prevent birdcaging under dynamic loads also contributes to extended service life and less maintenance.

Collapsed riser:

Bird cage effect due to compression

Anti-bird cage tapes:

Aramid Fabric

Aramid fabric with polymer layer

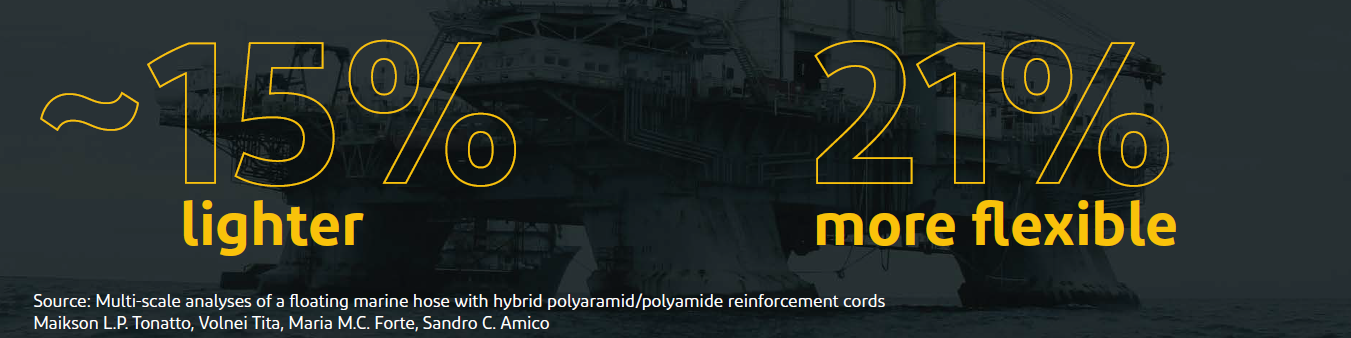

Floating Hoses Reinforced With DUPONT™ KEVLAR®

Kevlar® offers significant advantages for floating hoses in offshore oil and gas applications by making them lighter, more flexible and durable. Its high strength-to-weight ratio reduces the hose’s weight, easing transport, handling and improving buoyancy, while its flexibility allows hoses to move smoothly with ocean currents, reducing stress on connectors.

Compared to solutions made with polyester, Kevlar® is:

Mooring Lines Reinforced With DUPONT™ KEVLAR®

DuPont™ Kevlar® material maintains better creep versus UHMWP and it has a higher durability versus steel. Thereby delivering structural integrity over time with minimal elongation. This stability under load makes Kevlar® ideal for reliable performance in harsh marine environments, while also offering a lighter, more flexible alternative.

Reinforced Thermoplastic Pipes With DUPONT™ KEVLAR®

Kevlar® in reinforced thermoplastic pipes (RTPs) offers easy installation while enabling higher pressure ratings through its unmatched strength, flexibility and corrosion resistance. Kevlar® also enables lighter, more durable solutions than fiberglass due to its superior fatigue resistance.