A need to change the industry paradigm around comfort

To serve end-users with a new testing protocol

66% feel their body armor is not as comfortable as it could be¹

1Source: Lippincott brand research North American market study, September 1 2020

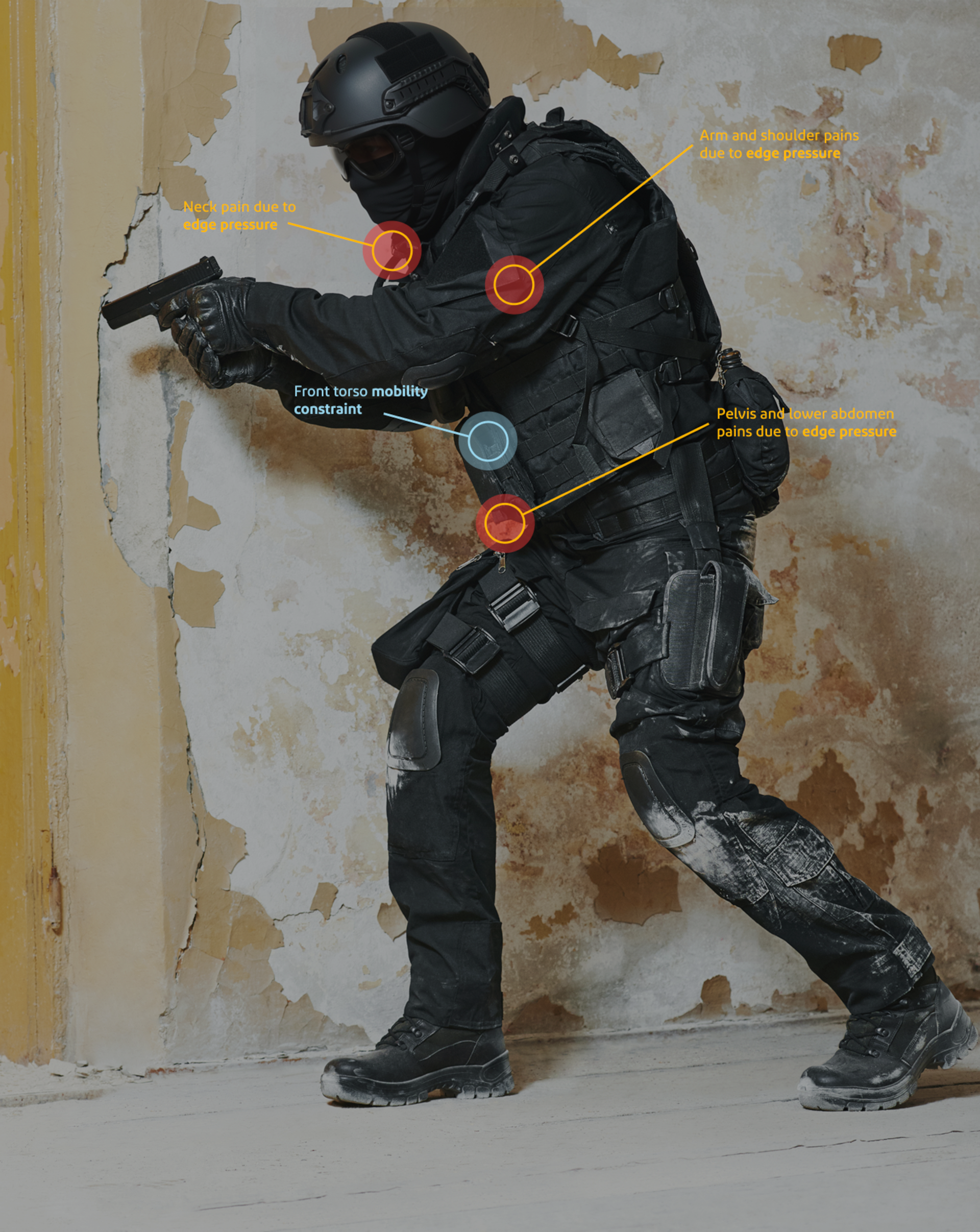

The cost of discomfort

Discomfort and restricted mobility can cause wearers to adjust or remove armor too soon, leaving them vulnerable. Fatigue and strain weaken focus, slow reactions and raise the risk of injury.

Leveraging on wear trials and end-user feedback, DuPont collaborated with Hohenstein to introduce a new testing protocol to standardize comfort and mobility assessments, helping to ensure protective gear enhances safety, endurance and operational effectiveness.

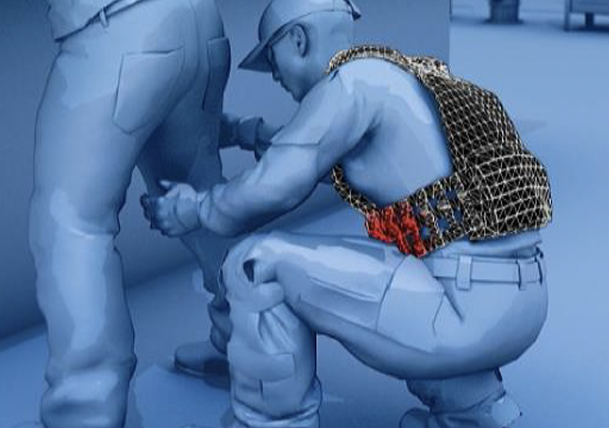

Real body motion to develop 3 new testing methods

By focusing on scenarios and movements identified by law enforcement and military forces, we developed tests based on anatomical principles that more effectively capture mobility constraints and sources of discomfort.

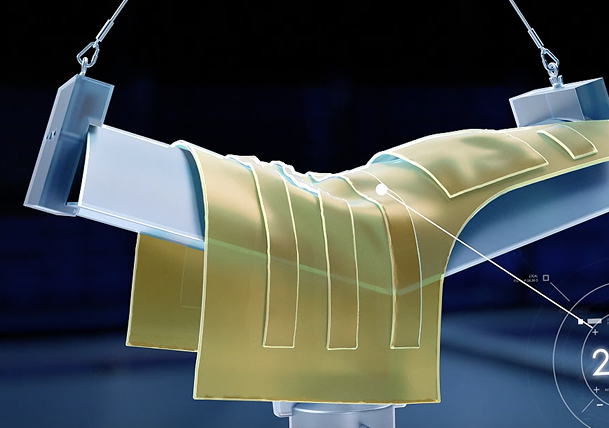

Lower costal bending test

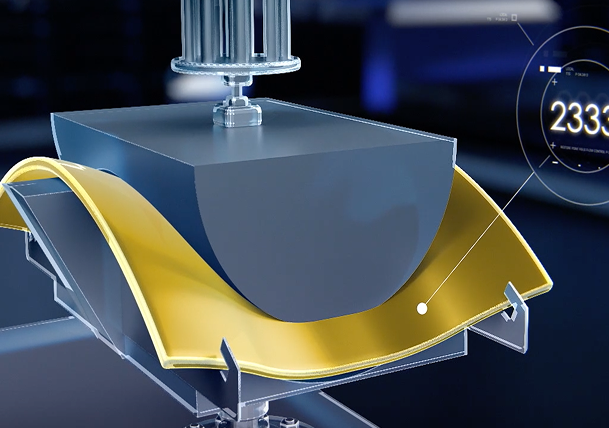

Double curvature compression test

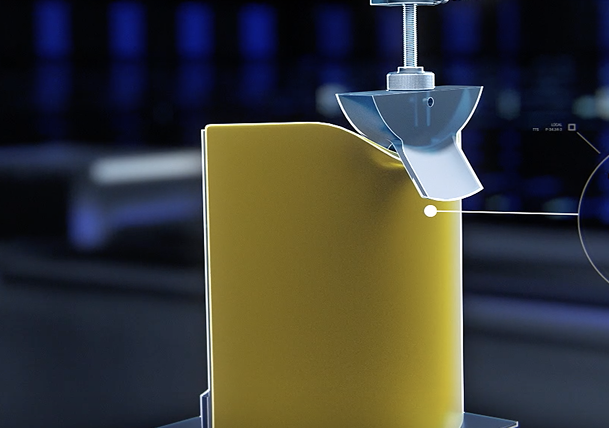

Edge pressure test

Watch the video

Innovative testing for real-world performance

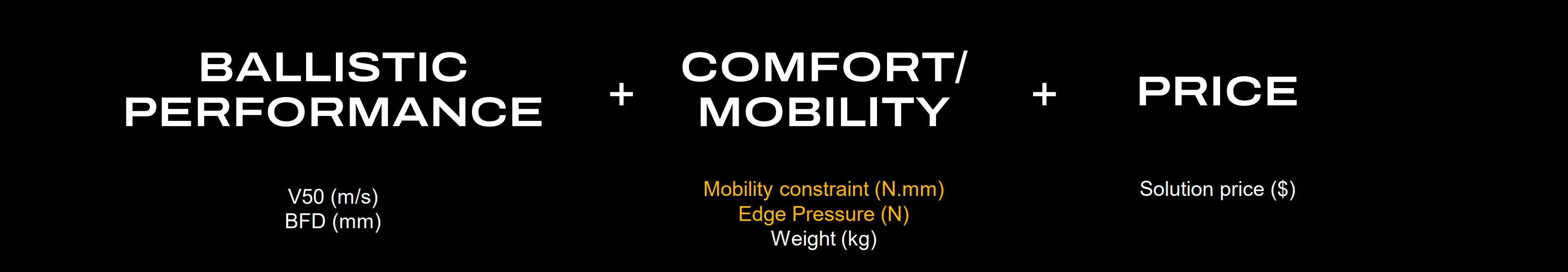

These new mobility and comfort protocol redefine body armor evaluation, offering materials and designs in support of maximum agility and long lasting wearability without sacrificing ballistic performance.

LCB - Lower costal bending test

DCC - Double curvature compression test

Critical factors in armor selection

These new test methods provide measurable data on comfort and mobility, giving purchasers of soft body armor critical insights allowing for more informed decisions. With concrete numbers now available, safety, mobility and long-term wearability can be objectively evaluated, helping to ensure armor that can truly protects without compromising comfort.

Involving the value chain at the Service of end-users

Integrating these tests into procurement and early evaluation can drive material innovation, advancing flexible high-strength fibers that can enhance protection, mobility and long-term wearer support.

To develop more flexible innovative fibers and structures with high mechanical properties

To maximize combination of materials to reduce pains and mobility constraints while meeting required ballistic performance

To specify a test method for comfort and mobility assessment into tenders and in early stage of the candidate selection process

A new standard for mobility & comfort

Together, DuPont and Hohenstein are setting a new test protocol in body armor. By combining DuPont’s protective expertise with Hohenstein’s independent textile testing, we help manufacturers provide top ballistic performance while maximizing comfort and mobility.

This testing protocol is available to all manufacturers, providing an industry-wide benchmark to help ensure armor protects without hindering those who wear it.

Ready to put your ballistic solutions to the comfort and mobility test?

DuPont believes this information to be reliable. It may be subject to change as additional knowledge and experience are gained. It is not intended as a substitute for any testing you may conduct to determine for yourself the suitability of our products and information for your particular purpose. Since conditions for use are outside the DuPont’s control, DUPONT DE NEMOURS, INC. AND ITS AFFILIATES MAKE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE AND ASSUMES NO LIABILITY IN CONNECTION WITH ANY USE OF THIS PRODUCT AND INFORMATION. This information is not intended as a license to operate under or a recommendation to infringe any trademark, patent or technical information of DuPont or other persons covering any material or its use.

©2025 DuPont. All rights reserved. DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, ℠ or ® are owned by affiliates of DuPont de Nemours, Inc. unless otherwise noted.”