The application

Industrial milling of mined ore – from large rocks and boulders to fine particles – is a demanding process. Massive semiautogenous mills – commonly known as SAG mills – use milling balls, as well as the weight of the ore itself, to break down the ore into smaller particles – a process known as comminution.

The turning and tumbling of tons of ore within these mills creates a harsh environment with high heat and constant vibration. Downtime for these mills is costly, and repairs can be dangerous – which makes preventive maintenance and proper lubrication extremely critical.

The challenge

To meet mill MRO expectations and the heavy industrial demands of these large-scale ore-processing plants, the lubrication solution needed to help control maintenance costs by reducing unscheduled stops due to loosened bolts and bolt failure. The optimal solution also needed to protect the bolts from the dusty and abrasive by-products of the comminution process.

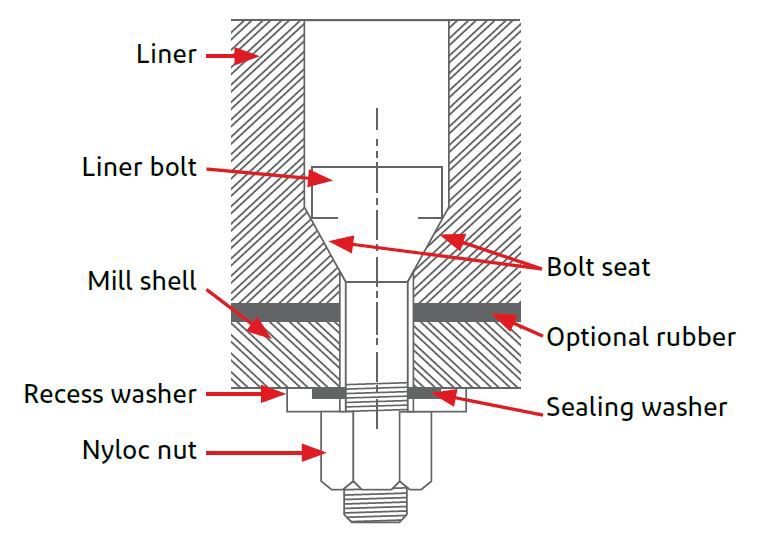

Mill liner bolts secure the protective liner to the inside of the mill. Proper lubrication is essential in ensuring the applied torque is converted to elongation and clamping force, minimizing the risk of tension loss and fatigue failure.

The customer

Relining Minerals – a distributor of specialty industrial bolts for mining operations, with locations in Peru and Panama – was in search of a lubricant to protect SAG mill liner bolts from extreme environmental conditions, including high temperatures and harsh vibrations. With the help of Mining Products and Service (MPS) – an Australia-based company specializing in the design, supply and optimization of wear components for the mining industry – Relining Minerals launched studies to determine the solution that would best protect the bolts from elongation beyond the stress yield threshold that was causing bolt deformation and failure.

In these trials, the companies sought to achieve consistent bolt tensions by standardizing the type of lubricant used, how the lubricant was applied to the fastener assembly and correct operation of the torque tools. They tested several different types of lubricants, including MOLYKOTE® P-74 Assembly Paste. Because Relining Minerals provides not only the bolts, but also the lubricant and the technical support, the distributor wanted a solution it could rely on – not simply as a recommendation to customers, but as its own preferred solution.

The solution

During the research and testing process, Relining Minerals and MPS put MOLYKOTE® P-74 Assembly Paste – selected for its low coefficient of friction – to the test by comparing it to other leading lubrication solutions.

During bolt tensioning trials, MPS brought in a pulp lifter liner, configured with M48 liner bolts, from a 36-foot SAG mill. The test jig was used to calibrate actual torque/bolt load and, through proper lubrication, get it closer to the calculated torque/bolt loads to reduce the variation in the bolt loads achieved.

During bolt tensioning trials, MPS brought in a pulp lifter liner, configured with M48 liner bolts, from a 36-foot SAG mill. The test jig was used to calibrate actual torque/bolt load and, through proper lubrication, get it closer to the calculated torque/bolt loads to reduce the variation in the bolt loads achieved.

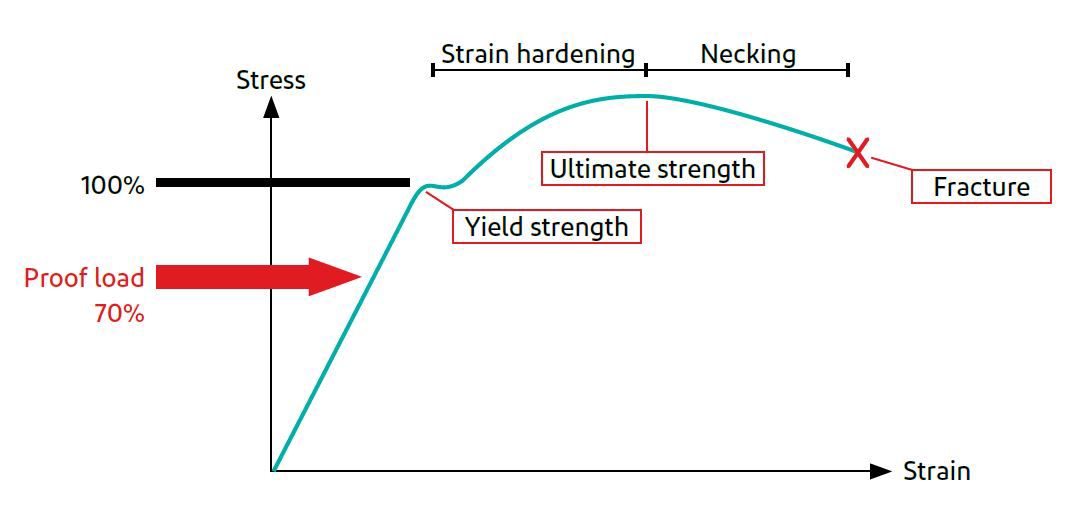

In the trials, which compared MOLYKOTE® P-74 Assembly Paste with the most commonly used lubricants on mine sites, MOLYKOTE® P-74 Paste consistently outperformed the best of the competitive lubricants by at least 10%. The trials also demonstrated that the method of lubricant application to the assembly also was important. If the liner bolts aren’t correctly installed and are under-tensioned, they become fatigued and fail. MOLYKOTE® P-74 Paste helps reduce friction so a higher percentage of the applied torque is converted to elongation and clamping force.

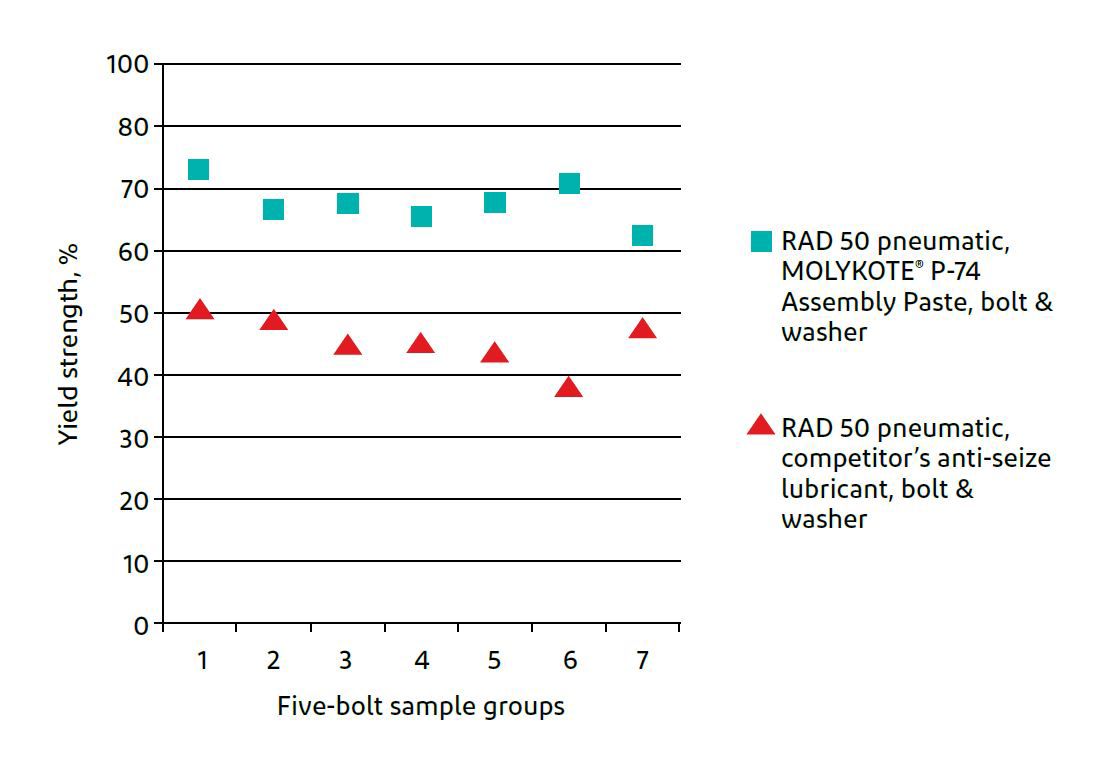

In the graph below, MOLYKOTE® P-74 Paste was compared to the most commonly used anti-seize lubricant. This trial was done using a RAD 50 torque multiplier and best practices established from the tensioning trials, including:

- Hardened cup washer

- Lubricant applied to bolt thread and washer face

- Taking the torque multiplier to stall, releasing the trigger, then reapplying the trigger until the gun stalls again

MOLYKOTE® P-74 Assembly Paste was able to increase the proof strength of the bolts and more reliably prevent deformation of the bolts under stress. In tests that averaged the results of seven different five-bolt sample groups, MOLYKOTE® P-74 Paste was able to maintain a yield strength much closer to 70% than the competitive lubricant.

A clear choice for demanding environments

After seeing the results of the testing, Relining Minerals began recommending MOLYKOTE® P-74 Assembly Paste as its preferred specialty lubricant for mill liner applications. The company found that the paste kept bolt elongation in the optimal range with minimal tension loss, resulting in reduced bolt failures and downtime.

By preventing the bolt and liner from loosening, the distributor found that the lubricant helped reduce unscheduled stops – which increased productivity at the plants, which often are the entry point in the ore-refining process. It also resulted in reduced risk of accidents, as the calibration and adjustment work required to address loosened bolts or bolt failure commonly is a source of physical danger.

Another added benefit to the distributor and its customers was that the paste’s lack of metal content helped minimize environmental impact.