Sunroof Guide Lubrication with MOLYKOTE® Specialty PAO Grease

Case Study

Application

Sliding sunroofs and panoramic roofs for a global Tier 1 supplier.

Challenge

An application-matched lubrication technology that could deliver consistently low friction was needed to ensure proper opening and closing forces across a range of sliding-roof designs. Low-temperature performance was a critical design parameter. Other key requirements added to the development challenge: The solution needed to address priorities such as a clean appearance, reduced noise, safety for vehicle occupants, compatibility with plastic materials, durability for extended service, and design flexibility for larger and more complex sliding roofs in the future.

White lithium greases were well-known, trusted and relatively economical lubricants for applications with sliding surfaces under heavy loads. However, none of the available options exactly met all of the performance specifications set by the sunroof design and engineering teams.

Solution

The specific MOLYKOTE® PAO grease first developed for basic sunroof designs has grown in step with the manufacturer. Starting in the manufacturer’s home market and then expanding into other geographies, this MOLYKOTE® brand Smart Lubrication™ solution is now maximizing functionality and comfort in all types of sunroofs, including popular panoramic roofs.

For more than two decades, as sliding roofs became an integral part of today’s vehicles in many regions, the MOLYKOTE® synthetic PAO lubricant has delivered key advantages and benefits:

- Superior performance with excellent lubrication and noise-damping capabilities

- Enhanced comfort with reduced noise, judder and vibration during sliding-roof opening and closing

- Consistent smoothness and reliability at temperatures from -45 to +120°C (-49 to +248°F)

- Increased safety by promoting a faster response to potential obstructions

- Good lightweighting potential with less friction and wear on different metals and resins

- Added cleanliness with low bleed, less oil separation and resistance to dirt buildup

- Extended service life with resistance to water washout, evaporation and corrosion

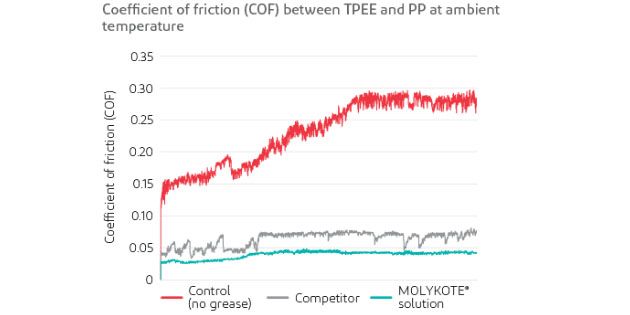

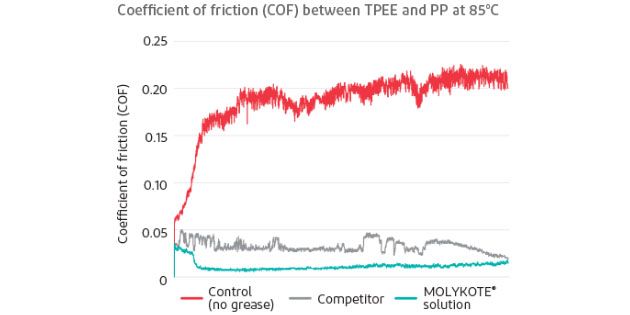

Comparative performance testing*

*Refer to the full case study for additional performance testing data.