Two-Part Adhesives Driving Faster, Simpler Assembly

Article

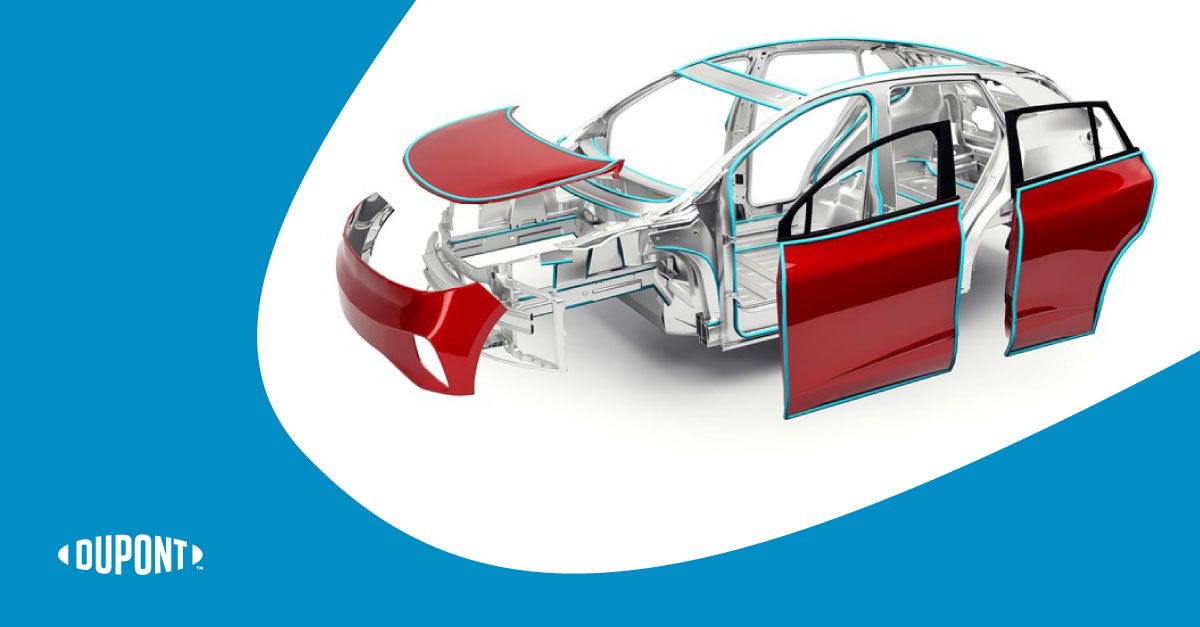

When production speed, flexibility, and sustainability matter, OEM engineers and design teams need adhesives that get the job done. DuPont two-part (2K) adhesives are the right choice. These formulations are a proven, high-performance solution that help optimize assembly and deliver higher toughness with bonds that last.

Why choose 2K?

Our 2K formulations deliver reliable performance on real production lines. They combine proven performance benefits with practical manufacturing advantages: faster handling, less oven reliance, and fewer surface-prep steps.

- Optimized manufacturing cost: Less prep, fewer primer steps, and faster handling reduce cycle time and labor.

- Greater flexibility: Ambient and accelerated cure options as well as low-viscosity grades fit various production setups.

- Sustainability: No-bake formulations help reduce energy use and greenhouse gas emissions during vehicle body manufacturing.

- Global supply: Manufacturing available around the world to support regional production and ease of supply.

Meet the 2K family

The broader two-part adhesive family offers engineers the option to choose the right balance of toughness, flexibility, cure speed, and cost for their unique application.

Each 2K formulation is engineered for modern trends, such as primerless bonding, cold-pumpable viscosities for easier dispensing, acceptance of higher mix ratios, and compatibility with modular assembly lines.

BETAMATE™ 2K Epoxy:

- Proven performer delivering high strength, medium-to-high toughness for crashworthiness, and component integrity.

- Fast handling with ambient cure and no-bake options.

- Bond to most metals and accept a range of cure accelerators.

- Contamination tolerance to reduce or remove time-consuming prep.

- Ideal for structural and mixed-material bonding as well as battery applications.

BETAFORCE™ 2K Urethane:

- Higher elongation and flexibility to absorb movement and shock.

- Excellent adhesion to plastics and mixed materials.

- Suited for trim, closures, liftgates, roof bonding, and some battery assemblies.

BETAMATE™ 2K Epoxy-Acrylic Hybrid:

- Faster cure with versatile flexibility.

- Useful where quick throughput and toughness are both required.

Ready to evaluate 2K adhesives for your assembly process?

Contact us to learn more.