<span style="text-shadow: 2px 2px #000000">University healthcare system conducts plastics recycling pilot</span>

DuPont™ Tyvek® Healthcare Packaging provides valuable support

Most plastics used in healthcare packaging today are being disposed of in landfills or by incineration. This is a huge problem that will continue to grow as the total amount of plastics used globally in healthcare packaging is expected to increase from 14.6 billion pounds in 2020 to 18.8 billion pounds by 2025, based on a compound annual growth rate (CAGR) of 5.1%.1

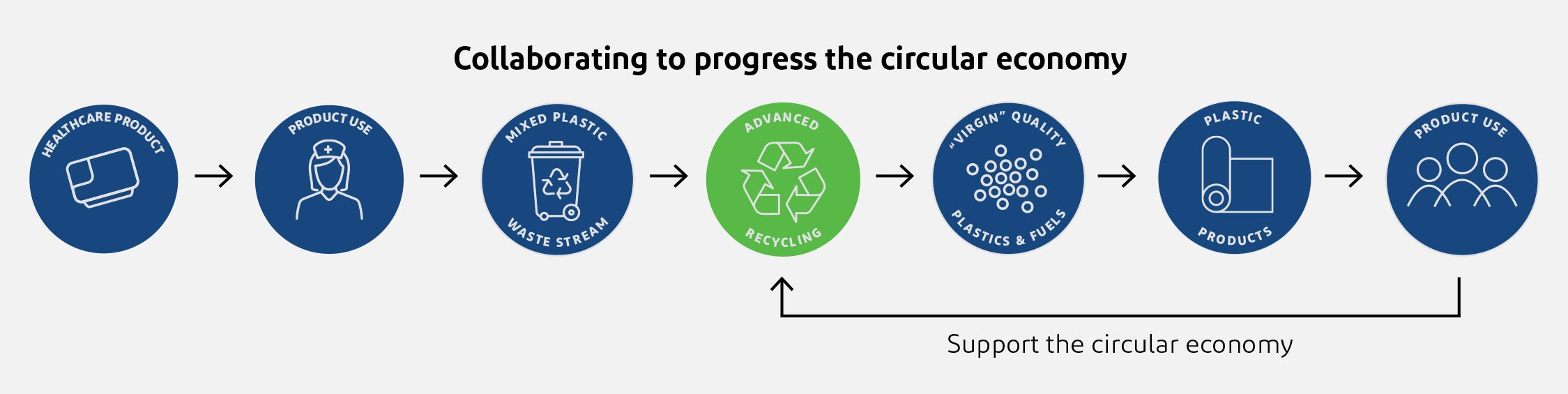

DuPont™ Tyvek® Healthcare Packaging is actively seeking ways to help enable everyone along the value chain to adopt recycling programs or practices that divert healthcare packaging waste— not only DuPont™ Tyvek® but other plastic waste—from landfilling or incineration, with the goal of driving towards circularity.

According to the Sustainability Leader at a large U.S. university healthcare system, a connection made with the DuPont™ Tyvek® Healthcare Packaging team through participation in the Healthcare Plastics Recycling Council (HPRC) was the springboard for a recycling pilot at her facility to reduce healthcare plastics that currently go into landfills. This Sustainability Leader noted that “the HPRC is a learning collaborative space that enables disconnected parties to begin to connect to solve overwhelming challenges.”

When DuPont™ Tyvek® Healthcare Packaging team members asked this Sustainability Leader if the university healthcare system where she worked would be interested in collaborating on a mixed plastics recycling pilot, she thought it was the perfect timing to build on two existing grassroots initiatives run by members of the facility’s Green Team, and she quickly went to work to get buy-in and ensure clinical engagement before beginning the in-depth planning process for a 2021 recycling pilot.

Getting started with in-depth planning

The first of many decisions was which areas to choose for the recycling pilot. Two outpatient surgery centers—one for women’s health and one for eyes and ears—were chosen. These smaller, self-contained areas that have one shift per day and are open only five days a week would serve as good test cases—and they have Green Team champions on staff who enthusiastically supported this initiative.

The next step was for the university healthcare system to build cross-functional alignment among the key stakeholders: the sustainability team, building management and the environmental services (EVS) custodial staff. Numerous consultations were held with recycling subject matter experts from the DuPont™ Tyvek® Healthcare Packaging team and Freepoint Eco-Systems LLC, the advanced recycler receiving the collected waste.

Site visits by members of the DuPont™ Tyvek® Healthcare Packaging team and representatives from Freepoint helped identify and assess medical device packages and other products (such as tubs, basins and pitchers) that could and couldn’t be collected for the recycling pilot. During these visits, members of the DuPont™ Tyvek® Healthcare Packaging team and representatives from Freepoint also answered questions from nurses and staff leaders; reviewed proposed collection, storage and pick-up areas; and discussed with the EVS team how this would change typical material flow.

- KAT DOERR, Vice President of Plastic Supply Origination at Freepoint Eco-Systems

Identifying which materials and products can or cannot be accepted into recycling processes is a significant barrier when it comes to recycling healthcare plastics. That’s because the healthcare plastic waste stream is made up of mixed resin/polymer types and forms—both flexibles and rigids—which create challenges when it comes to recycling.

“For this pilot program, we targeted the collection of non-hazardous, uncontaminated healthcare plastics,” said Kat Doerr, Vice President of Plastic Supply Origination at Freepoint Eco-Systems. “Our pyrolysis process operates on a feedstock of olefinic materials, so we used this as the leading criteria to identify acceptable and non-acceptable materials for collection practices,” she explained.

With the Freepoint team providing guidance as to what types of polymers are desired for their process, the DuPont™ Tyvek® Healthcare Packaging team members could leverage their experience in the market to identify with the healthcare facility leaders the specific packaging and products that could be collected from the waste stream for the pilot study.

- NICK PACKET, Industry Vertical Manager for the DuPont™ Tyvek® Healthcare Packaging team

Each hamper or bin included signage outlining what could and could not be recycled. This poster, developed by the DuPont™ Tyvek® Healthcare Packaging team, contains photos to make it easier to know on the spot what is and isn’t acceptable for purple bag waste. It was also distributed electronically to all employees and posted in central areas.

After considering several options for where to accumulate the purple bags until pickup by Freepoint, a compromise was reached with building management to use open top roll offs in the parking lot. But this would prove to be problematic. People walking across the parking lot would often throw trash such as fast-food cups and wrappers into the roll offs. Contractors doing renovations onsite dumped ceiling tiles, old carpeting and other materials, and a landscaping contractor threw empty pesticide containers into them.

Due to these contamination issues, the team switched to a closed top “doghouse” roll off container with side doors in one area and were able to move one open top roll off to a fenced-in area; however, there were still some issues with contamination. So they began working with one of their suppliers to set up a reverse-hauling arrangement. Now, purple bags are placed in aggregated spaces for daily pickup by the supplier who then moves them to their warehouse space and places them into roll offs, which are then hauled monthly to Freepoint.

Driving adoption through training and communications

The DuPont™ Tyvek® Healthcare Packaging team and the university healthcare system’s Sustainability Leader, Zero Waste Manager and Green Team champions worked together to conduct in-person and virtual training sessions for every participating department to get this pilot up and running.

“The engagement on the ground has been really encouraging,” said the Zero Waste Manager. “It’s a complicated process. Compared to commingled recycling, the purple bag program requires extensive training. What can go in the bins is not intuitive, so you need committed frontline staff to make the program operational.”

There was a lot of ongoing communication with the DuPont™ Tyvek® Healthcare Packaging team and Freepoint to help assess the program and resolve questions and concerns. During the first few months of the pilot, most of the communications were related to contamination issues.

When composition analysis reports provided by Freepoint showed contamination in initial pickups, emails were sent to remind the staff of what was and wasn’t acceptable waste for the purple bag program. Additional training sessions were also conducted to reinforce this information and provide staff with the opportunity to ask questions.

Investigation revealed that contamination during collection in the clinical setting was minimal and was caused by undesirable materials such as polyvinyl chloride (PVC) being put into the purple bags and a few instances of breakroom/food trash being placed in the bags. The majority of the contamination had occurred at the aggregation points/roll off containers located outside.

As a result, some logistical changes were made, such as removing a collection bin from a breakroom, moving a roll off container to a fenced-in area and switching to a “doghouse” roll off container in another area, as previously noted.

Measuring the impact

During the first 9 months of the pilot, a total of 13,792 pounds of plastic waste was diverted from landfill. Over time, contamination decreased significantly and improved training around what materials should be collected from the clinical setting, as well as changes to aggregation containers proved themselves out, making contamination no longer an issue and underscoring the importance of ongoing communication and training.

Overall, the recycling pilot at these two outpatient centers has been deemed a success and provided valuable learnings that can be applied as the university healthcare system looks to expand the purple bag program beyond the initial two areas.

According to the Zero Waste Manager, “Feedback has ranged from overwhelmingly positive to a total lack of interest or enthusiasm. And we know from the volumes that we are only capturing a fraction of the total hard-to-recycle plastics due to some people not participating in the collection efforts.”

“We can take away barriers, figure out funding and logistics, provide training, track and monitor data, but at this point we can only ask people to volunteer,” said the Sustainability Leader. “We are starting to build accountability into our culture but we don’t have a penalty for non-compliance. We need recycling goals to be set for all to meet from the top down.”

The Zero Waste Manager added, “The opportunity to recycle plastics within healthcare systems is enormous, so investing the time and resources to set up a functional recycling program has the potential to make a huge difference.”

Key learnings

- Cross-value chain collaboration can be a catalyst for successful recycling programs.

- Setting up a recycling program can make a real difference in decreasing what is currently going to the landfill and help healthcare institutions achieve waste reduction goals.

- A successful recycling program is so much more than just setting up bins; it requires a project manager(s) to help ensure adoption and success

- Clear, frequent communication is essential.

- Initial training will likely need to be followed up with additional training.

- Long-term planning, as well as funding for hauling and supplies, is required to ensure ongoing success.

About Freepoint

Freepoint Eco-Systems LLC is in the business of securing supplies of waste plastic that is not being recycled and converting that waste into reusable products via its advanced recycling facilities. Freepoint Eco-Systems is engaged in business operations in the U.S., Europe and Asia. FreepointEcoSystems.com

About HPRC

In 2010, DuPont joined with other leading companies in the healthcare, recycling and waste management industries to form the Healthcare Plastics Recycling Council (HPRC). We are proud to be a founding member of this technical coalition that is working to inspire and enable viable, safe and cost-effective recycling solutions for plastic products and packaging used in the delivery of healthcare. hprc.org