Video Option for Hero

FAQ Component - Synched with Resource Center is ready to use!

In the call I remember that team would like to have a FAQ section - I think it was through the SafeSPEC but, if needed I can arrange something like this:

Frequently Asked Questions

Question 1

Donec luctus sem sit amet risus ultricies volutpat. Curabitur hendrerit libero vitae mauris pulvinar varius. Proin at lobortis libero. Sed placerat leo purus, in elementum turpis condimentum id. Quisque hendrerit dignissim nisi in consequat. Fusce ut laoreet est, vitae scelerisque lacus. Mauris justo risus, bibendum ut commodo vitae, tempor vel est. Maecenas tristique non metus eu tincidunt. Duis gravida tristique elit, sed suscipit sapien rhoncus vel. In magna sem, facilisis nec velit non, pharetra feugiat enim. Morbi condimentum tellus eu sem pretium, volutpat varius elit euismod. Quisque facilisis accumsan dui, sed pharetra arcu. Nulla vitae faucibus felis. Praesent auctor sed arcu sit amet blandit. Aenean quis finibus dolor.

Question 2

Donec luctus sem sit amet risus ultricies volutpat. Curabitur hendrerit libero vitae mauris pulvinar varius. Proin at lobortis libero. Sed placerat leo purus, in elementum turpis condimentum id. Quisque hendrerit dignissim nisi in consequat. Fusce ut laoreet est, vitae scelerisque lacus. Mauris justo risus, bibendum ut commodo vitae, tempor vel est. Maecenas tristique non metus eu tincidunt. Duis gravida tristique elit, sed suscipit sapien rhoncus vel. In magna sem, facilisis nec velit non, pharetra feugiat enim. Morbi condimentum tellus eu sem pretium, volutpat varius elit euismod. Quisque facilisis accumsan dui, sed pharetra arcu. Nulla vitae faucibus felis. Praesent auctor sed arcu sit amet blandit. Aenean quis finibus dolor.

Question 3

Donec luctus sem sit amet risus ultricies volutpat. Curabitur hendrerit libero vitae mauris pulvinar varius. Proin at lobortis libero. Sed placerat leo purus, in elementum turpis condimentum id. Quisque hendrerit dignissim nisi in consequat. Fusce ut laoreet est, vitae scelerisque lacus. Mauris justo risus, bibendum ut commodo vitae, tempor vel est. Maecenas tristique non metus eu tincidunt. Duis gravida tristique elit, sed suscipit sapien rhoncus vel. In magna sem, facilisis nec velit non, pharetra feugiat enim. Morbi condimentum tellus eu sem pretium, volutpat varius elit euismod. Quisque facilisis accumsan dui, sed pharetra arcu. Nulla vitae faucibus felis. Praesent auctor sed arcu sit amet blandit. Aenean quis finibus dolor.

Question 4

Donec luctus sem sit amet risus ultricies volutpat. Curabitur hendrerit libero vitae mauris pulvinar varius. Proin at lobortis libero. Sed placerat leo purus, in elementum turpis condimentum id. Quisque hendrerit dignissim nisi in consequat. Fusce ut laoreet est, vitae scelerisque lacus. Mauris justo risus, bibendum ut commodo vitae, tempor vel est. Maecenas tristique non metus eu tincidunt. Duis gravida tristique elit, sed suscipit sapien rhoncus vel. In magna sem, facilisis nec velit non, pharetra feugiat enim. Morbi condimentum tellus eu sem pretium, volutpat varius elit euismod. Quisque facilisis accumsan dui, sed pharetra arcu. Nulla vitae faucibus felis. Praesent auctor sed arcu sit amet blandit. Aenean quis finibus dolor.

Document Library

I remember that team would like to feature the garments - such as maskes, gloves, garments etc. In this case, I believe in order to obtain a charming view - good quality & designed images are needed. Kimtech had a very good example - like the

Gloves

Suspendisse eget lectus gravida, scelerisque lectus vitae, finibus nisl. Fusce sapien justo, sodales viverra lacinia id, ultrices a quam. Integer massa nulla, laoreet eget neque eget, maximus malesuada orci

Masks

Suspendisse eget lectus gravida, scelerisque lectus vitae, finibus nisl. Fusce sapien justo, sodales viverra lacinia id, ultrices a quam. Integer massa nulla, laoreet eget neque eget, maximus malesuada orci

Garments

Morbi rhoncus libero leo, eget sagittis augue malesuada at. Vestibulum id aliquet tortor. Curabitur non tristique mi, eu porttitor quam.

It is always possible to use different background colors to create contrast - I would probably need the hex code of Tyvek blue

For a wide range of industries, processes must be kept clean and uncontaminated. DuPont materials are used to create a variety of clothing for these controlled environments with different levels of protection, durability, and comfort in a variety of styles, including coveralls, lab coats, frocks, hoods, sleeves, and shoe & boot covers.

Our leading brands of cleanroom apparel and accessories include: Tyvek® IsoClean®, a fabric-like material made from a patented flash-spinning process that creates an excellent barrier to dry particles, microorganisms, and non-hazardous liquids and is offered in a wide range of design and processing options to protect wearer and process from chemical contamination; Tyvek® Micro-Clean 2-1-2, which delivers the particle barrier, durability, and comfort of Tyvek® with a blue polymeric resin coating on both sides of the fabric; and ProClean® garments and accessories for your controlled environment and non-hazardous manufacturing applications.

Gloves

Suspendisse eget lectus gravida, scelerisque lectus vitae, finibus nisl. Fusce sapien justo, sodales viverra lacinia id, ultrices a quam. Integer massa nulla, laoreet eget neque eget, maximus malesuada orci

Masks

Suspendisse eget lectus gravida, scelerisque lectus vitae, finibus nisl. Fusce sapien justo, sodales viverra lacinia id, ultrices a quam. Integer massa nulla, laoreet eget neque eget, maximus malesuada orci

Garments

Morbi rhoncus libero leo, eget sagittis augue malesuada at. Vestibulum id aliquet tortor. Curabitur non tristique mi, eu porttitor quam.

We should also merge the callouts in the scrollable component. Maybe we can only keep the Sustainability but in a different format. Such as below

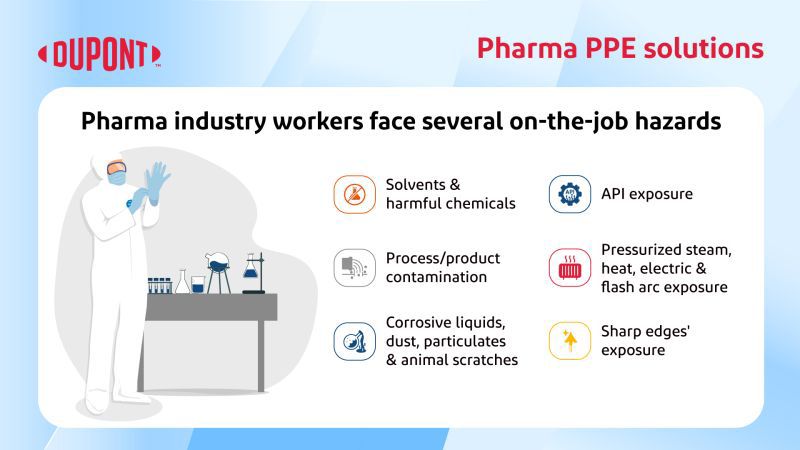

Companies are assessing the biohazards that are present in their environment and refining their policies, procedures, and PPE to protect their workers.

Humans are the biggest source of contamination in a cleanroom, making cleanroom apparel selection a critical consideration.

DuPont™ Tyvek® IsoClean® delivers an ideal balance of protection, durability and comfort. Additionally, with our single use cleanroom garments, both inventory and use costs are predictable.

Our ProClean® brand includes four levels of protection for your controlled environment applications and non-hazardous general manufacturing apparel needs.

These safe, clean, and strong shoe covers are designed for controlled environment applications, as well as non-hazardous general maintenance and dirty jobs.

Donec luctus sem sit amet risus ultricies volutpat. Curabitur hendrerit libero vitae mauris pulvinar varius. Proin at lobortis libero. Sed placerat leo purus, in elementum turpis condimentum id. Quisque hendrerit dignissim nisi in consequat. Fusce ut laoreet est, vitae scelerisque lacus. Mauris justo risus, bibendum ut commodo vitae, tempor vel est. Maecenas tristique non metus eu tincidunt. Duis gravida tristique elit, sed suscipit sapien rhoncus vel. In magna sem, facilisis nec velit non, pharetra feugiat enim. Morbi condimentum tellus eu sem pretium, volutpat varius elit euismod. Quisque facilisis accumsan dui, sed pharetra arcu. Nulla vitae faucibus felis. Praesent auctor sed arcu sit amet blandit. Aenean quis finibus dolor.

Donec luctus sem sit amet risus ultricies volutpat. Curabitur hendrerit libero vitae mauris pulvinar varius. Proin at lobortis libero. Sed placerat leo purus, in elementum turpis condimentum id. Quisque hendrerit dignissim nisi in consequat. Fusce ut laoreet est, vitae scelerisque lacus. Mauris justo risus, bibendum ut commodo vitae, tempor vel est. Maecenas tristique non metus eu tincidunt. Duis gravida tristique elit, sed suscipit sapien rhoncus vel. In magna sem, facilisis nec velit non, pharetra feugiat enim. Morbi condimentum tellus eu sem pretium, volutpat varius elit euismod. Quisque facilisis accumsan dui, sed pharetra arcu. Nulla vitae faucibus felis. Praesent auctor sed arcu sit amet blandit. Aenean quis finibus dolor.

Donec luctus sem sit amet risus ultricies volutpat. Curabitur hendrerit libero vitae mauris pulvinar varius. Proin at lobortis libero. Sed placerat leo purus, in elementum turpis condimentum id. Quisque hendrerit dignissim nisi in consequat. Fusce ut laoreet est, vitae scelerisque lacus. Mauris justo risus, bibendum ut commodo vitae, tempor vel est. Maecenas tristique non metus eu tincidunt. Duis gravida tristique elit, sed suscipit sapien rhoncus vel. In magna sem, facilisis nec velit non, pharetra feugiat enim. Morbi condimentum tellus eu sem pretium, volutpat varius elit euismod. Quisque facilisis accumsan dui, sed pharetra arcu. Nulla vitae faucibus felis. Praesent auctor sed arcu sit amet blandit. Aenean quis finibus dolor.

Out of Scope but this was my suggestion to Replace Safespec & RC & WTB Sections

Cleanroom clothing that gives you a peace of mind

DuPont understands your need to do everything possible to reduce contamination risks in your controlled environments.

One of the areas in which safety and health are of paramount importance is in cleanrooms and controlled environments. The DuPont cleanroom clothing portfolio offers a comprehensive selection of single-use cleanroom garments and accessories designed for use in pharmaceutical, medical device, biotech and electronic settings that require high standards for particle and microbiological contamination control.

Indeed, DuPont™ Tyvek® garments have a long history of use in cleanrooms due to their excellent barrier to particles, microorganisms and non-hazardous liquids. They offer an ideal balance of protection, durability, comfort and contamination control. They are available in many styles for different cleanroom and controlled environment applications and are packaged and certified to meet local market requirements. With the DuPont Controlled Environments offering, you get the advantage of a wide range of proven, science-based solutions that help keep your cleanroom environment protected.

In many industries that require high standards for particle and microbiological contamination control to ensure the highest quality of the finished products, there are strict quality-assurance procedures and protection must be assured throughout all processes. Operators represent the biggest source of contamination inside cleanrooms. They are responsible for 75% of all contaminants – both from the operators themselves and from their cleanroom garments.

Operator contamination can be reduced through training and impeccable hygiene, but it can’t be eliminated. There is only one way to prevent particles generated by operators from contaminating the cleanroom: use cleanroom garments. They are the only barrier between the operator and the production environment. The 2020 draft of the Good Manufacturing Practice guidelines (GMP) Annex 1 states that ‘cleanroom garments should retain particulates shed by the body’. Sufficient cleanroom clothing is therefore required to prevent contamination and protect operators from hazardous substances.

Industries

Industries

Tyvek® is tough, yet lightweight and soft.

Tyvek® offers an ideal balance of protection, durability, and comfort.

Tyvek® acts as a breathable barrier against particles and bacteria.

Tyvek® repels aqueous liquids and liquid aerosols.

Tyvek® is inherently low linting and abrasion resistant

Tyvek® is tough, yet lightweight and soft.

Tyvek® offers an ideal balance of protection, durability, and comfort.

Tyvek® acts as a breathable barrier against particles and bacteria.

Tyvek® repels aqueous liquids and liquid aerosols.

Tyvek® is inherently low linting and abrasion resistant

Why Tyvek® IsoClean®?

DuPont understands your need to do everything possible to improve productivity and reduce risk in your controlled environment. The DuPont Controlled Environments (CE) portfolio offers a comprehensive selection of single-use cleanroom apparel and accessories designed for use in various settings that require high standards for particle and microbiological contamination control.

The highest performing garments in our product line are made from Tyvek®, which has been used to make high-quality cleanroom garments for more than 25 years. Tyvek® is made by DuPont with a proprietary flash-spinning process that creates continuous fibers of high-density polyethylene that are randomly distributed and non-directional.

Tyvek® IsoClean® cleanroom garments, designed for single use, offer meaningful advantages in today’s challenging cleanroom environments, including:

- Quality—single-use garments are not subjected to multiple cycles of wearing, laundering, and sterilization, so fabric barrier and strength are consistent and predictable.

- Flexibility—the DuPont single-use apparel program allows you to order only the quantities that you plan to use, which offers flexibility as your needs change.

- Cost control—single-use garments help eliminate budget uncertainties associated with garment repair, damage, and loss, helping you to better predict expenditures.

Garment Fabrics

Various economical, low-linting fabrics for your controlled environment.