Once in a Century: Hazmat Instruction Through a Pandemic

By Patrick J. Jessee, Hazardous Materials Training Program

Manager at Northeastern Illinois Public Safety Training Academy (NIPSTA)

Well, 2020 was one for the record books! The year started off as any other year in the Chicagoland area: cold weather, recuperating from the holiday season, planning on the courses to be offered at our training academy and reorganizing before kicking off the firefighting academy classes. Illinois firefighters are required to complete operations-level training (NFPA 472) as part of their basic training. Additionally, we provide hazardous materials incident command training and technician-level training, as well as short duration subject-specific courses.

Then talk of a small bug started rumbling around, first on the internet, then in the news, and eventually in every person’s daily conversation – COVID-19, a strange name for a virus that everyone would soon know. The realization hit everyone like a lightning bolt: the world was in the middle of a global health crisis, a pandemic. The social behavior and standards in place throughout our society created risks that would need to be addressed in order to slow the spread of this airborne transmissible illness.

Those working in public safety and hazardous materials response are familiar with talking about personal protective equipment (PPE), including gloves, masks, suits and respirator standards. But these terms would soon start permeating the public discourse as civilians who never before had a need for these products in their professional or private lives would be looking to have them for the protection of their family, workers and themselves. A global run and supply shortage of equipment that was vital to the public safety mission would occur.

Today’s technology, treatments and understanding of science are significantly different than they were during the last pandemic – the Spanish Influenza virus of 1918, just over 100 years ago. The advances in these fields have created opportunities for instruction that simply would not have existed, even a few years ago. These technologies would be needed to continue training future firefighters.

During the COVID-19 pandemic, fire departments continued to respond to everyday events along with the increased burden of medical responses brought on by the pandemic. At the same time, training needed to keep occurring to bring in new employees to replace those retiring or leaving the field. At NIPSTA, we understood that we could not stop training and needed to adapt to the new rules of engagement for workplaces and training in order to keep supplying new firefighters who could fulfill the public safety needs of the communities we serve.

To accommodate this, we first looked at the requirements for our training to decide what could be completed remotely and what required hands-on teaching. Both firefighting and hazardous materials programs have cognitive (mental) and psychomotor (tactile) training components. Fortunately, our academy had been using Jones and Bartlett’s book, Fundamentals of Fire Fighter Skills and Hazardous Materials Response, for their training. This NFPA-compliant book is approved by the Illinois Office of the State Fire Marshal to be used for training. A bonus with Jones and Bartlett’s material was that it already had online learning modules built into the books with access codes issued to each book. This also provided students with quizzes, lectures, flashcards, videos and other study material. The students’ performance, hours online and what they looked at were all logged to prove their self-study. This would be the backbone for the cognitive learning for the students. The NIPSTA hazardous materials training staff would then focus on reinforcing the cognitive learning when they would report for their in-person, hands-on (psychomotor) training.

While the basic firefighter students would study the hazardous materials lectures online, we were significantly aware that hazmat is its own language. Science terms, new concepts and equipment, and procedures would be a challenge for someone to pick up on their own without some guidance or previous exposure. To address this concern, we added in “office hours” for the students following their lectures. These office hours were similar to what one might experience at college, where a professor or teaching assistant would be available to answer specific questions at a specific time. Using online programs, such as Zoom, we would set a specific time and allow the students to visit with an instructor to ask specific questions about their learning and hazmat. This allowed a face-to-face opportunity to clarify hazmat issues in real time.

The students would then minimize their on-campus time, therefore reducing their risk of contracting COVID-19 from each other. Once on campus, the students were required to complete a daily health screening, including a health questionnaire and temperature check. Class sizes were reduced to minimize the number of students in the classroom, masks were required and larger classrooms were utilized to maximize social distancing.

Administratively, NIPSTA maintained a situational awareness of the current directives from CDC as the pandemic evolved, adjusting our processes, notifications, cleaning procedures and other changes to make the learning experience as safe as possible.

The DuPont™ Tychem® Trainer Advantage Program (TTAP) assisted the hazardous materials training portion by allowing us to use some of the training props, such as the fabric swatches and Level A pressure test kit, to add tactile learning to the students’ experience. This was done in small group discussions and cleaned before any contact with the next group.

At the end of this, NIPSTA emerged as the only training institution in Illinois to offer an uninterrupted fire and hazmat training program. This was due partly to the diligence of our Executive Director, Jill Ramaker, but also largely due to the support from the instructors and the commitment of the students for a safe learning experience.

Patrick J. Jessee is the Hazardous Materials Training Program Manager at Northeastern Illinois Public Safety Training Academy (NIPSTA) in Glenview, IL and is a Lieutenant/Paramedic with the Chicago Fire Department, Special Operations-Hazardous Incident Team at O’Hare Airport. In his 21 years with the department, he has contributed to public safety in a variety of leadership and operation-level roles, including EMS, Fire Suppression & Rescue, Special Operations (Technical Rescue and Hazardous Materials), Instructor Staff, and Headquarters Staff. He holds multiple graduate degrees in Public Policy and Administration (Northwestern), Threat and Response Management (University of Chicago), and Biology (University of Illinois at Urbana Champaign), as well as undergraduate degrees in Biology (DePaul) and Chemistry (Southern Illinois University at Edwardsville).

Hoarding disorder & hazmat considerations

By Daniel Hammel, North America Marketing Lead – Chemical Industrial, DuPont Personal Protection

What is hoarding?

A person with hoarding disorder finds it persistently difficult to throw away possessions due to a perception of the item’s necessity, leading to the accumulation of many items. This is true even when the items hold little to no value, and discarding (or even the thought of discarding) the items can lead to distress for the person. The American Psychiatric Association (APA) estimates that hoarding disorder occurs in 2 to 6 percent of the population.

Symptoms

Hoarding disorder can range from mild to severe cases. The Mayo Clinic provides some signs and symptoms of someone with hoarding disorder, which may include:

- Excessive acquisition of unnecessary items or items that exceed the space available

- Persistent difficulty in discarding items, regardless of an item’s value

- A feeling of necessity when it comes to holding onto items

- A feeling of upset with the thought of throwing away hoarded items

- Collection of clutter to the point where the surroundings are no longer usable

- Tendency toward indecision, perfectionism, avoidance and/or procrastination

- Problems with planning and organizing

Hazmat risks

The excessive accumulation and refusal to throw away items may present itself in an unsanitary collection of trash and food. Additionally, hazardous particles and vapors, mold, ammonia and biological hazards may be present in the home of someone with hoarding disorder. Bloodborne pathogens may also be present within the hoarded items, and remediation of a hoarded home may release toxins into the environment.

Some people may hoard animals as pets, sometimes having hundreds of indoor or outdoor animals on the premises. The sheer number of animals makes the proper care of them extremely difficult, leading to unsanitary conditions for both the residents of the property and the hoarded animals.

The American Society for the Prevention of Cruelty to Animals (ASPCA) provides signs that someone may be an animal hoarder:

- Having numerous animals and potentially not knowing the total number of animals that they have

- Deteriorated home, which could include broken windows and furniture; holes in the walls or floors; and excessive clutter

- Strong smell of ammonia and visible signs of dried animal feces, urine or vomit

- Emaciated, lethargic and poorly socialized animals

- Presence of fleas and vermin

- Person neglects himself or herself and is isolated from their community

- Person insists that the animals are well taken care of, despite clear evidence to the contrary

The ASPCA estimates that 250,000 animals are hoarded every year. Sadly, the accompanying neglect often results in the animals’ illness, starvation and death.

Other hazards

Hoarding can lead to unsafe living conditions, as the collected items may block pathways and be kept on surfaces (e.g., counters, desks, stairs, appliances, etc.), piling up as high as the ceiling. This puts the person with hoarding disorder, other housemates and emergency personnel at risk of slips, trips and falls; overhead hazards; blocked passageways during an emergency; and exposure to hazardous materials. Various cut and puncture hazards may be present within the items that are hoarded, such as used needles, broken glass and sharp metal objects. The hoarded items may also spread to the outdoor area, as the inside fills to capacity.

The National Fire Protection Association (NFPA) reports that compulsive hoarding behavior leads to serious fires, injuries and deaths. For the following reasons, this poses a threat to responding fire departments, as well as to the occupants of the home where the hoarding takes place and to nearby neighbors:

- Blocked exits can prevent or complicate escape from a burning home. Injuries may occur to people trying to escape, as items may fall on them or become a tripping hazard.

- First responders cannot move quickly through a home that is filled with clutter.

- First responders can be trapped in the home if exits are blocked.

- The sheer weight of the hoarded items can lead to the collapse of the building structure, especially once water has been used to extinguish the fire.

- Neighbors living next to a home where hoarding takes place may be affected by excessive smoke and fire conditions.

Personal protective equipment (PPE)

Due to the many hazards that a hoarded home may contain, PPE should be used by first responders and anyone entering the home. Depending on the situation, consider using respiratory protection; protective clothing and gloves; and head, eye and foot protection. Visit SafeSPEC™ to see some of the PPE solutions that DuPont Personal Protection provides.

References:

https://www.psychiatry.org/patients-families/hoarding-disorder/ what-is-hoarding-disorder

https://www.mayoclinic.org/diseases-conditions/hoardingdisorder/symptoms-causes/syc-20356056

https://www.aspca.org/helping-people-pets/animal-hoarding

https://www.nfpa.org/Public-Education/Fire-causes-and-risks/ Behavioral-risks/Hoarding

Hazmat through History – Transportation Regulations

By Kathryn Novelli – Marketing Specialist

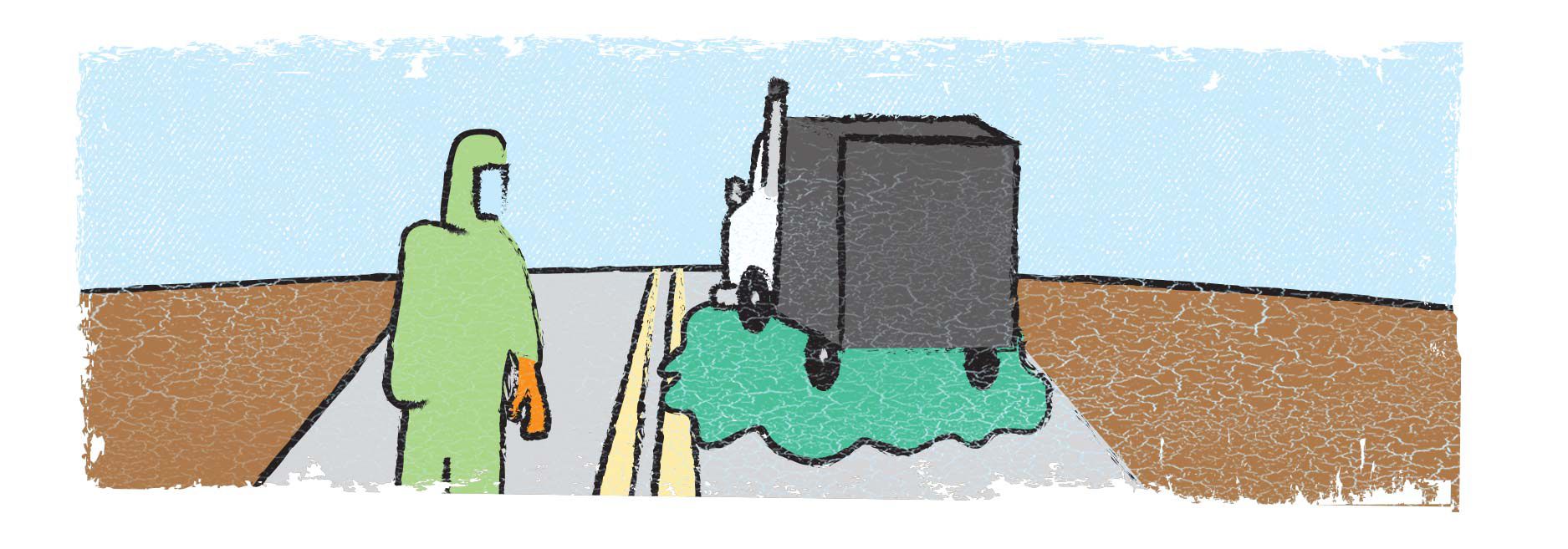

On December 24, 2013, a tractor-trailer leaking hydrogen cyanamide, an ingredient used in pesticides, caused an all-day emergency response and cleanup near Tumacacori, Arizona. The U.S. Department of Transportation (DOT) classifies hydrogen cyanamide as a Class 8 hazardous corrosive material, defined as “a liquid or solid that causes full thickness destruction of human skin at the site of contact within a specified period of time.” The spill of approximately only one half-gallon of the corrosive chemical caused a brief shutdown of Interstate 19, as well as responses from safety agencies that included the Arizona Department of Public Safety, Santa Cruz County Sheriff’s Office, Santa Cruz County Office of Emergency Management, Nogales HazMat Team, Arizona Department of Transportation, U.S. Border Patrol and multiple fire departments. Fortunately, no injuries were reported in the incident.

The transportation of hazardous materials is serious business. The umbrella of “hazmat” encompasses materials that are radioactive, flammable, explosive, corrosive, oxidizing, asphyxiating, biohazardous, toxic, pathogenic or allergenic, as well as physical conditions of materials such as compressed gases and liquids, hot materials and other characteristics that render them hazardous in specific circumstances. Transporting such materials can potentially be dangerous and requires special care and consideration.

The United States has been working to face the challenges of transporting hazardous materials since the mid-1800s. In the early days of hazmat transportation regulation, standards were developed incrementally and regionally. However, this decentralized system of regulation was largely unsupervised, and regional inconsistencies led to dangerous situations.

The first hazmat transportation regulations in the U.S. were overseen by the Coast Guard and applied to seafaring vessels. The regulations were primarily intended to maintain the safety of the ships themselves. In 1871, a federal law prohibited the use of passenger ships to transport combustible and flammable materials. In 1887, as railway transportation became increasingly important during the settlement of the American west, the Interstate Commerce Commission (ICC) was established to create a federal regulatory agency that would oversee the railway industry. The ICC was primarily established to ensure fair pricing in the railroad industry, but also gained oversight of the transport of hazardous materials by railway. By 1927, the regulatory power of the ICC had expanded to incorporate all methods of transport including rail, water, road and air.

By the 1970s, hazardous waste dumping had become an extremely prevalent issue. Enforcement of ICC regulations was inconsistent. Community concern regarding the dangers of hazardous dump sites prompted landfills to refuse hazardous waste, which may have unintentionally contributed to an increase in illegal waste dumping. In 1975, the Hazardous Materials Transportation Act (HMTA) was ratified, with a primary objective to provide protection against the “risks to life and property inherent in the transportation of hazardous material in commerce.” The HTMA established the DOT to improve the regulatory and enforcement authority of the U.S. federal government. The newly formed DOT unified U.S. regulations, categorized hazardous materials into nine distinct classes and defined inspection methods standards for each class of hazardous materials. This classification system is still used today in hazardous materials placarding systems.

Today, the U.S. government includes several regulatory agencies that have oversight of hazardous material transportation, including the DOT, EPA and OSHA. In 2004, DOT established the Pipeline and Hazardous Materials Safety Administration (PHMSA), which leads development and enforcement of hazmat transportation regulation in the U.S. In addition to U.S. regulatory bodies, the United Nations Economic and Social Council (ECOSOC) provides guidance and procedures for the shipment of hazmat materials. Specific groups that focus on smaller subsets of hazmat transportation include the International Air Transport Association, the International Maritime Organization and the Intergovernmental Organisation for International Carriage by Rail.

When the DOT was established in 1975, it estimated that “75% of hazmat transportations violated existing regulations due to a lack of inspection and poor coordination among the various entities overseeing hazmat transportation.” Thanks in part to improved hazmat transportation regulation, hazardous materials fatalities, injuries, accidents and property damage have decreased dramatically, on average, since the 1970s.

To learn more about how to protect yourself from different hazardous materials, and to find out which DuPont products offer suitable protection for your needs, visit safespec.dupont.com.

Tychem® 2000 Tape Introduction – Part 2

By Michael Sieber

Product Development Engineer, DuPont Personal Protection

Sufficiently and simply protecting the face, lungs and body should be a priority for any first responder needing to enter a hot or warm zone. You might recall that we introduced our low-hazard chemical protective DuPont™ Tychem® 2000 Tape product within the last issue of The Glow Worm. Tychem® 2000 Tape is a recent addition to the Tychem® family of products. This new chemicalresistant tape helps keep personal protective equipment (PPE) in place while providing the same level of chemical resistance as Tychem® 2000 fabric.

Utilizing chemical-resistant tape as a part of your team’s suite of PPE options can help secure interfaces such as the sleeve to glove, pant leg to boot, storm flaps or other closures. In 2018, 25,000 recordable skin diseases were reported by the Bureau of Labor Statistics, at a rate of 2.2 injuries per 10,000 employees. (For comparison, respiratory illnesses were reported at a rate of 1.7 per 10,000 employees.) Most chemicals are readily absorbed through the skin and can contribute to the dose absorbed by inhalation of the chemical from the air. Many studies indicate that absorption of chemicals through the skin can occur without being noticed. Non-volatile chemicals, which are relatively toxic and which remain on work surfaces for long periods of time, are particularly dangerous. This is why permeation is commonly referred to as “the silent killer.” For those donning chemical protective garments, having a low-hazard chemical protective tape that’s easy to use can help increase protection against such occupational exposure hazards.

Compared to other tapes used by hazmat teams and workplaces for chemical protection, Tychem® 2000 Tape provides a happy medium of protection, ease of use and cost. The tape is easy to apply, reposition or remove — similar to electrical tape. Its elasticity and lack of fibrous support structure allow the tape to be stretched for tight adhesion. Duct tape and other chemical protective tapes don't have the ability to stretch and tear as easily since they are reinforced with filament. If you are familiar with the history of chemical protective clothing, you may realize that depending on the suit and task, the need for taping of closures has decreased as suit design and overall PPE compatibility have improved. Recent PPE developments have reduced the need for taping by developing better interfaces and seams, and even negated use within some high-hazard suits. However, for low-hazard chemical protective garments or for those not sold as complete ensembles, taping might still be able to increase protection at critical interfaces, such as when connecting the glove to a sleeve using a glove ring. It should be noted that taping should not be used to provide chemical resistance in place of there not being any barrier present, since there is no way to guarantee a seal and one that is repeatable every time.

Tychem® 2000 Tape provides similar chemical protection compared to Tychem® 2000 garment fabric, including chemical permeation holdout against many inorganic acids and bases used in various industries and applications, as well as common industrial cleaning agents like bleach. This includes providing at least 30 minutes of protection against more than 40 chemical challenges using the 0.1 µg/cm2 /min breakthrough criteria as specified within ASTM F739. It is currently offered in 60-yard rolls at a nominal width of 2 inches. Like with other chemical tapes, although Tychem® 2000 Tape is an impermeable barrier film, it is not able to provide a completely liquid- or gas-tight barrier at your interface and thus your garment, glove and boots should be relied upon for the protection level which your task requires. Tychem® 2000 Tape should never be used within explosive or flammable environments, similar to other PPE elements that do not have flame resistance. Visit SafeSPEC™ to view all of the chemical permeation data for Tychem® 2000 Tape and to learn more about this innovative addition to your PPE ensemble.

Reference:

US Department of Labor, Occupational Health & Safety Administration Bureau of Labor Statistics—Supplemental News Release Tables: SNR07. Illness cases by category of illness – rates, counts and percent – industry division – 2018. https://www.osha. gov/dermal-exposure

Products and/or sales questions?

Share your stories, tips and tricks.

Resource library

Find technical information, videos, webinars and case studies about DuPont PPE here.