Back-end

DuPont solutions for precision testing and packaging without damaging delicate wafers

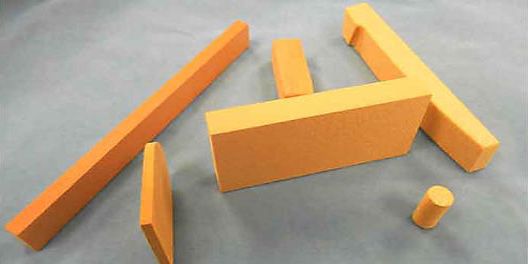

DuPont™ Vespel® parts for back-end processes won’t damage wafers like metal or ceramic. In fact, Vespel® prevents scratches and allows for greater precision.

Wafer handling, packaging, and testing are critical in delivering high-quality chips. At each step, there’s a risk of damage. Vespel® is ideal for semiconductor packaging, testing, and pick-up collets because it provides:

• Dimensional stability

• Low wear

• Low CTE (coefficient of thermal expansion)

• Low moisture absorption

Plus, Vespel’s® balanced mechanical properties allow for dimensional stability and precision machinability as a housing material of test sockets.

Ideas & innovations

Powered by a broad product portfolio and state-of-the-art expertise, we help our partners meet the critical industry demands of the electrical and electronics market.

Featured resources

Literature

DuPont™ Vespel® CR-4638 Technical Data Sheet

Case Studies

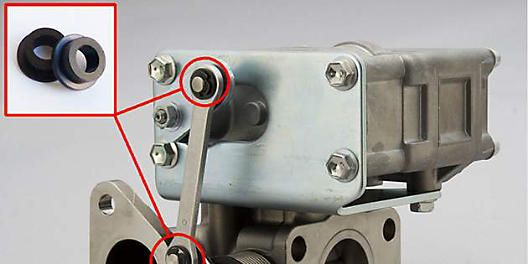

Vespel® Case Rings Boost Pump Efficiency and Safety

Vespel® Line Shaft Bearings for Pumps

Vespel® Glass Handling Sweep-Out Finger

Articles