DuPont™ Thermo-Man® Test Data Reinforce U.S. Refiner’s Trust in Garments Made with Nomex®

When it comes to selecting effective flame-resistant (FR) garments, test results speak louder than marketing claims.

That’s why a longtime safety manager at an independent global refiner and ethanol producer relies on hard data when evaluating protective apparel options for his workers.

With new FR fabrics and garments being introduced every year, he’s always weighing the choices for new FR garments from a number of manufacturers. To get the lab data he needs to make informed decisions, he relies on DuPont™ Thermo-Man®—one of the most advanced thermal burn injury evaluation devices in the world.

Putting FR Garments to the Test

In October 2016, this safety manager traveled to the state-of-the-art Thermo-Man® laboratory in Richmond, Virginia, armed with 37 different combinations of FR fabrics from various manufacturers. He wanted to see how they would perform when tested on this life-sized, instrumented mannequin system that can predict the number, location and severity of burn injuries resulting from a flash fire.

Among the oldest garments to be tested was a 6.0-ounce garment with Nomex® that had been put into service 20 years ago. As flames from 12 “Big Bertha” gas torches engulfed Thermo-Man® in a simulated flash fire, the safety manager expected the 20-year-old garment made of Nomex® to perform well, but not as well as a new garment given its age, wear and years of wash cycles. Turns out, he was pleasantly surprised.

That’s because the 20-year-old garment made of Nomex® performed as if it was brand new—with the same burn characteristics and body burn injury prediction. The Nomex® fiber had not broken down or lost its characteristics. Even after all those years in service, it performed like new.

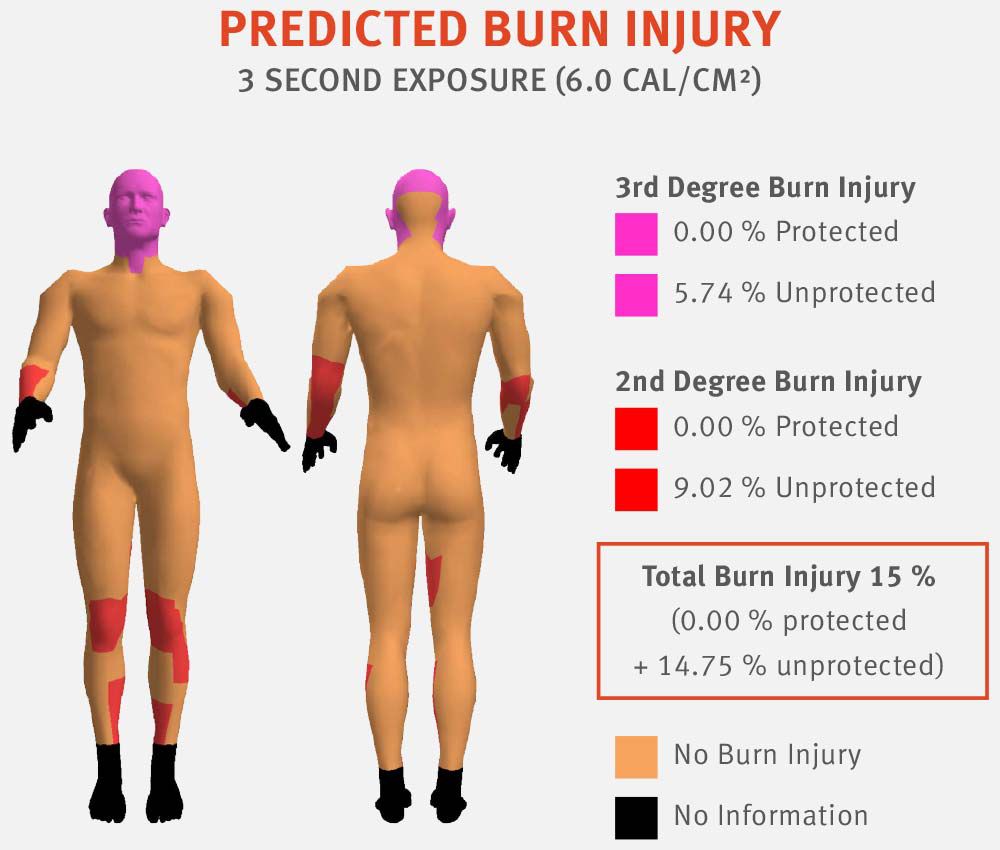

The predicted body burn injury results after a three-second burn (6.0 cal/cm2) of the 20-year-old garment made with Nomex® were: 15% total body burn with 9.02% second-degree and 5.74% third-degree burns (The predicted third-degree burns were to the unprotected face and head.)

On-site Visits from Thermo-Man® Make a Lasting Impression

Since that trip to Richmond, the safety manager has arranged for on-site visits from the Thermo-Man® demonstration unit at six of his company’s refineries in the Southeast region. During these events, he always tests the oldest garment he can find because of the discussions it prompts among workers.

“I have the Thermo-Man® demonstration unit come to our sites to give employees an opportunity to see this type of testing firsthand, so they can see what happens in a flash fire event and the importance of wearing the proper FR garment,” he said.

“It’s a great educational experience because Thermo-Man® lets employees see what the garment actually looks like after a burn event and learn what the percent body burn predictions will be. I’ve found that after the Thermo-Man® experience, employees gain a whole new appreciation for the FR garments that they are required to wear every day, and compliance with wear requirements becomes 100 percent.”

The Gold Standard for FR Garments

“I choose Nomex® for me and for those I’m responsible to protect because I know through my firefighting experience, industrial experience, testing and actual flash fire events that Nomex® protects people,” he added.

“I know it sounds like a cliché, but Nomex® is the gold standard for FR garments. It’s what every other fabric tries to mimic and tries to be. Nomex® is value, protection and durability—all in one fabric.”

For more information on DuPont PPE solutions to match tasks and hazards in the Oil & Gas industry, download our PPE Guidebook for Oil & Gas.