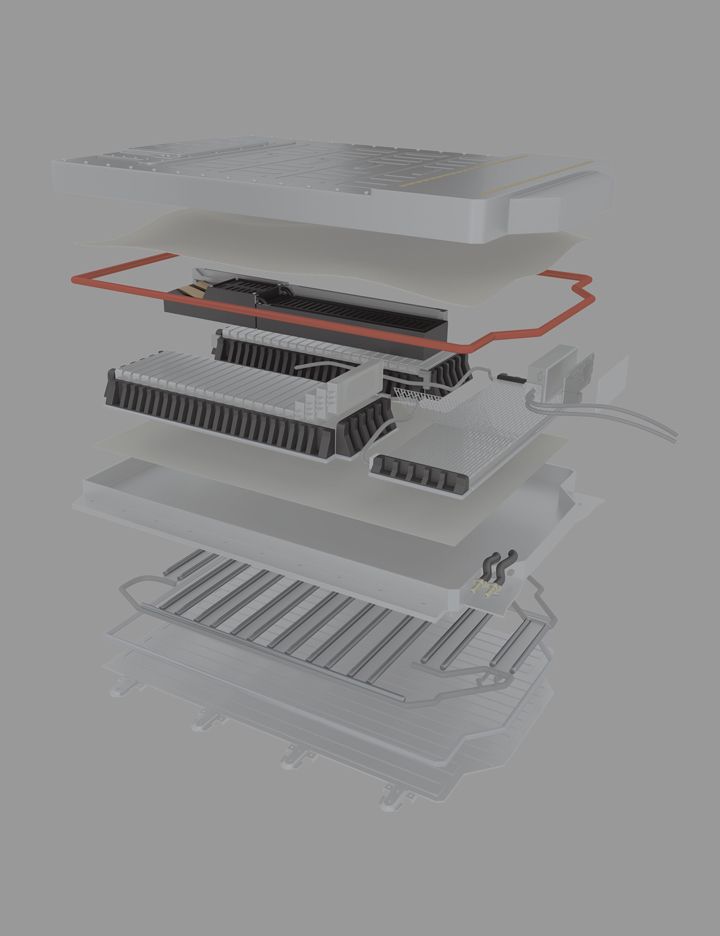

Battery Assembly

From design through production, our EV battery assembly adhesives maximize performance and durability

Reinforcement, structural integrity, NVH performance, accommodating multiple substrates, and improving manufacturing efficiencies are all part of the benefits of our battery assembly portfolio.

We collaborate closely with our customers to develop solutions that meet their specific requirements.

Adhesives technology that can bond dissimilar substrates results in strength, stiffness, crashworthiness, and better acoustical performance. Thermal conductive structural adhesives durably bond battery components while providing thermal control, crash durability, and production efficiency. Adhesives also allow manufacturers to use fewer components, increasing production efficiencies and optimizing cost for current and new battery pack designs.

We even develop with sustainability in mind – for us, for our customers, and for our planet. Innovations in adhesives technology can help reduce or eliminate solvents and plasticizers.

)