DuPont™ FAST® 1000 TD - Demo Video

DuPont™ Cyrel® FAST

A quarter century of platemaking success

For the past 25 years, our innovative DuPont™ Cyrel® FAST system has supercharged productivity and allowed printers, tradeshops, and convertors to bring their packaging designs to life faster, more sustainably, and more reliably.

To date, we are proud to have partnered with our customers to install over 1,500 FAST systems worldwide. Each year has brought continued innovation, ensuring that the Cyrel® FAST platemaking system continues to advance and set the pace to meet the increasing demands of even the most challenging printing designs.

Our Cyrel® FAST thermal processing system continues to deliver exceptional plate quality while minimizing the system's environmental footprint, improving process control to ensure print consistency.

FAST by Name, FAST by Nature

Simplifying complicated operations and enabling businesses to achieve shorter runs and faster turnarounds on a wide variety of substrates, the DuPont™ Cyrel® FAST thermal system earned its name because of how quickly it can provide the first plate. Impressively, this is all achieved while minimizing the environmental footprint of the platemaking process.

The FAST system can reduce platemaking time by up to an incredible 75%. The dry, solvent-free process eliminates the need to handle, distil and dispose of washout fluids and provides an extremely low-maintenance operation.

Compared to a solvent-based workflow, Cyrel® FAST thermal platemaking systems feature faster press setup times and improved printing performance, higher production speeds, and VOC emissions that are reduced by 99.8%, further reducing the global warming potential by 48%.

25 reasons to choose Cyrel® FAST

To celebrate 25 years of platemaking success with our DuPont™ Cyrel® FAST, we are proud to present 25 reasons why your business should consider this advanced thermal platemaking workflow. Cyrel® FAST is a complete ecosystem of specially formulated photopolymer plate and processing equipment, dedicated to offering the best solution for the thermal workflow.

From delivering the high-quality plates modern converters and tradeshops need, to maximizing productivity and efficiency, to successfully achieving sustainability objectives, the Cyrel® FAST System can certainly help YOU to achieve YOUR goals.

25 good reasons for you to invest in the Cyrel® FAST system

Better Press OEE

Cyrel® FAST enables faster press setup times, higher production speeds and high-quality printing to deliver better press OEE (Overall Equipment Effectiveness) and decreased startup waste.

Better Press OEE

Schur Star Success Case

“The Cyrel® FAST technology allows us to produce flexo plates extremely reliably and on demand since 2007. ” said Lene Høgh Madsen, Prepress Manager at Schur Star.

Schur Star Success Case

Read the Schur Star Case Study

Technical Service Capability

Our skilled maintenance technicians provide on-site support to resolve operational issues efficiently, while FAST processors offer remote access for quick troubleshooting to keep your equipment running smoothly.

Technical Service Capability

Decreased Production Time

Cyrel® FAST thermal system eliminates plate cleaning and drying, reducing production time by up to a staggering 75%!

Decreased Production Time

FAST by Nature

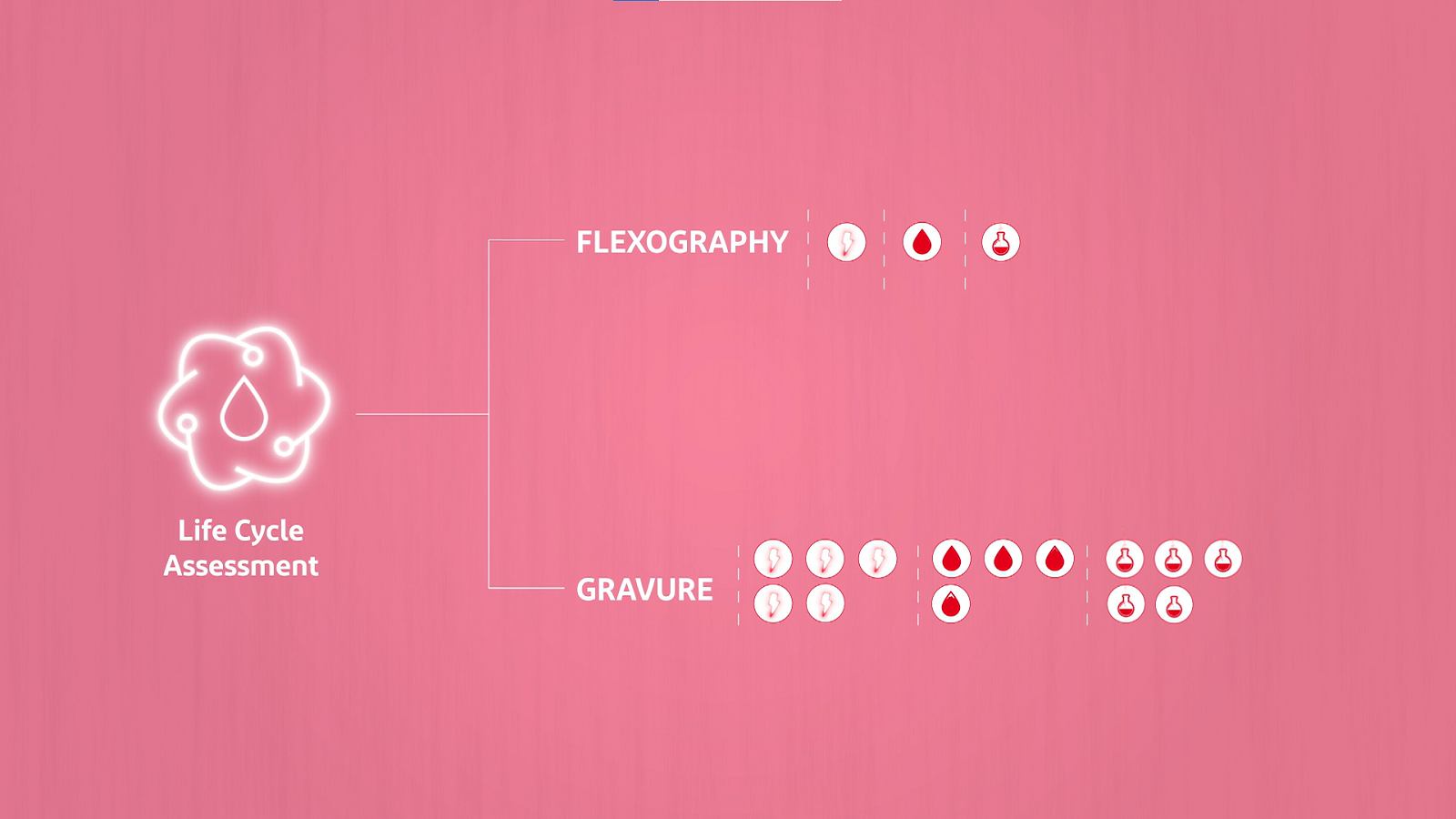

The dry, solvent-free FAST process eliminates the need for washout fluids - VOC emissions are reduced by 99.8% and global warming potential is reduced by 48% compared to a solvent-based workflow.

FAST by Nature

Read our LCA Report

High-Speed Platemaking

Cyrel® FAST units can perform under pressure and live up to their name, producing more thermal plates per shift at scale in comparison to solvent platemaking systems.

High-Speed Platemaking

Faster, Cleaner, Reliable

For a quarter of a century, DuPont™ Cyrel® FAST technology has enabled businesses to supercharge productivity and make their packaging designs a reality faster, cleaner and more reliably

Faster, Cleaner, Reliable

Amerplast Success Case

"It is key to maintain the perfect balance between functionality and integrity, print quality and sustainability in order to protect what’s most important: the packaged good,” said Ari-Pekka Pietilä, CS&MO Amerplast.

Amerplast Success Case

Read the Amerplast Case Study

A Proven Success

More than 1,500 installations worldwide (and counting)!

A Proven Success

We don’t stand still

We have recently expanded the range with Cyrel® Lightning LFH, a plate optimized for flexible packaging, compatible with the latest LED exposure and screening technology.

We don’t stand still

About Cyrel® Lightning LFH

Enhanced Fiber Printing

We can enable higher quality prints on lower quality substrates with our Cyrel® EASY FAST EFM plates, optimized for printing on fiber substrates.

Enhanced Fiber Printing

About Cyrel® EASY FAST EFM

FAST by Name

Plates per hour throughput is a key measure of success - the thermal processor is named FAST because of how quickly it can provide the first plate.

FAST by Name

More about FAST Processors

schäfer-etiketten Case Study

“The FAST 2000 TD Processor enables us to supply replacements to the press within 40 minutes, thus avoiding downtime and multiple makereadies,” said Tobias Gneiting, prepress manager at schäfer-etiketten.

schäfer-etiketten Case Study

Read the schäfer-etiketten Success Case

Smaller Runs, Faster

The Cyrel® FAST System makes it possible for businesses to meet the challenge of delivering smaller print runs and faster turnarounds while minimizing the environmental footprint.

Smaller Runs, Faster

The Right Equipment to the Right Size

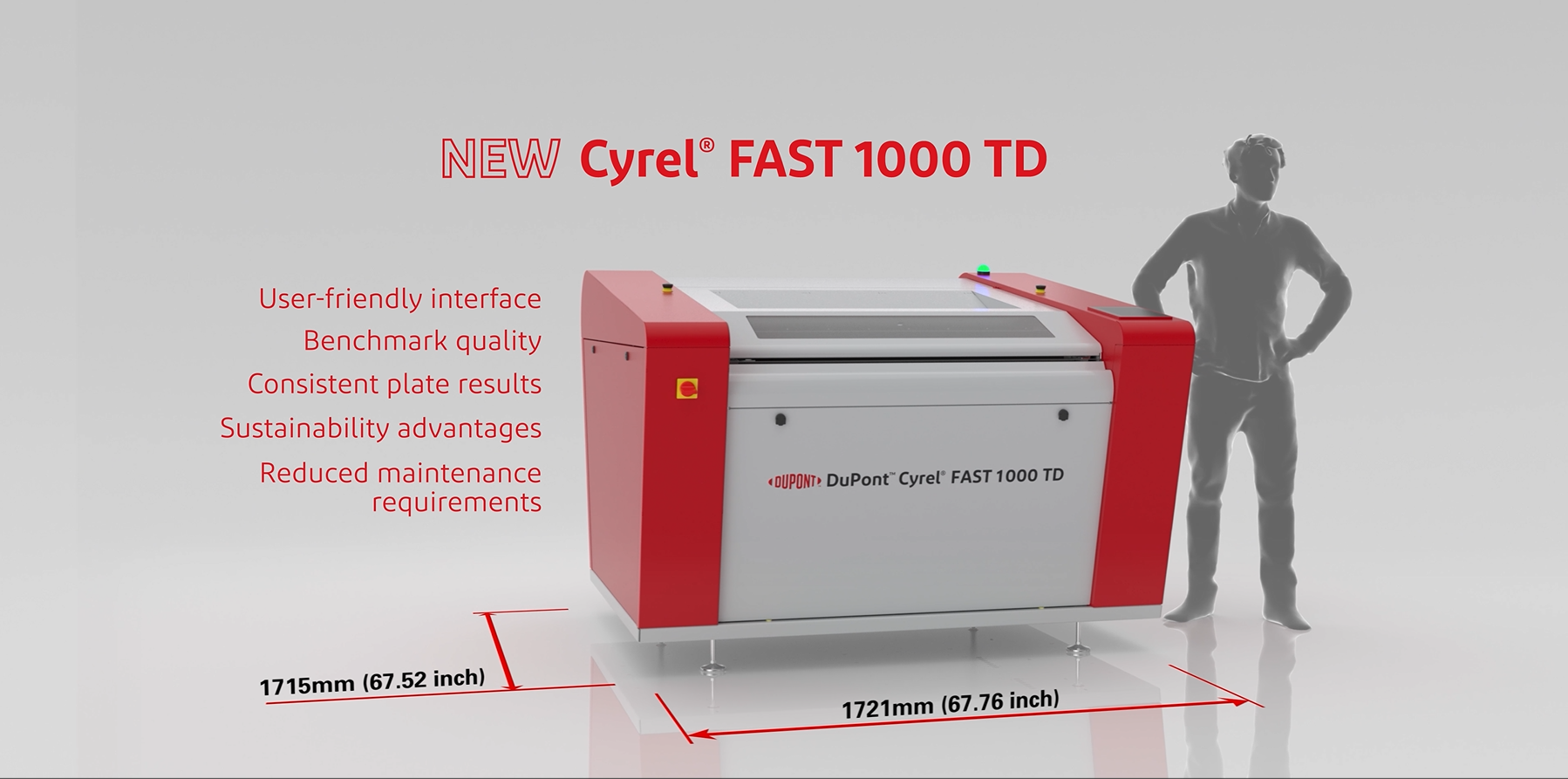

Continual development of the Cyrel® FAST processors’ performance has led to a complete line-up of the latest technology systems in all sizes and plate formats: 1000 TD, 2000 TD, 3000 TD.

The Right Equipment to the Right Size

More about FAST Processors

Ongoing Innovation

Ongoing innovation and dedication ensure each subsequent generation of Cyrel® FAST processors continues to improve to meet the stringent demands of both today’s and tomorrow’s tradeshops and converters.

Ongoing Innovation

Incredible Versatility

With Cyrel® FAST, platemakers have access to a complete system and family of flexo plates for practically all flexo printing and packaging applications.

Incredible Versatility

Supreme Reliability

The reliability of DuPont Cyrel® FAST thermal processors is well-known and proven through a large install base, exhaustive field experience, and detailed customer feedback.

Supreme Reliability

Reproflex Success Case

"Flexibility is key for us and our customers. With Cyrel® FAST we converted five label customers” said Jesper Haagen, co-owner of Reproflex Scandinavia A/S, from Denmark.

Reproflex Success Case

Read the Reproflex Success Case

A Legacy of Innovation

DuPont invented the first photopolymer flexographic plate in 1974 to provide a higher quality, more productive, and less expensive alternative to existing flexographic printing methods.

A Legacy of Innovation

Faster AND Cleaner Plates

Cyrel® FAST technology reliably delivers quality plates faster AND cleaner. With its catalytic oxidizer, the thermal processor releases virtually no VOC through the exhaust during plate production.

Faster AND Cleaner Plates

Efficient to Run

Data shows that Cyrel® FAST reduces the electricity consumption for platemaking by >80% compared to a solvent workflow.

Efficient to Run

Save on Space

By removing the solvent still and dryer unit, the Cyrel® FAST system reduces emissions, cuts energy demands, and optimizes space—minimizing environmental and physical impact.

Save on Space

Boost Productivity

Cyrel® FAST is designed to be easy to operate, reducing the learning curve for operators and minimizing setup errors.

Boost Productivity

Contribute to meet your ESG objectives

Cyrel® FAST minimizes your operation’s environmental footprint—something sustainability-focused customers increasingly demand to achieve their objectives.