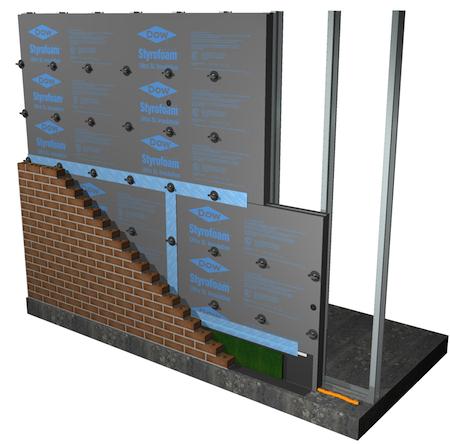

DuPont™ Styrofoam™ Brand Cavitymate™ Ultra XPS Insulation

Durable, High R-Value, Cavity Wall Insulation<br>U.S. HFC Regulation Compliant Formulation

DuPont™ Styrofoam™ Brand Cavitymate™ Ultra XPS Insulation

Durable, High R-Value, Cavity Wall Insulation<br>U.S. HFC Regulation Compliant Formulation

Features & Benefits

Specifications

Standard Sizes

| Thickness | Width | Length | R-Value | Edge Treatment |

|---|---|---|---|---|

| 2.18 in. | 15.75 in. | 8 ft. | 12.2 | Square Edge |

| 2.18 in. | 16 in. | 8 ft. | 12.2 | Square Edge |

| 2.5 in. | 15.75 in. | 8 ft. | 14.0 | Square Edge |

| 2.5 in. | 16 in. | 8 ft. | 14.0 | Square Edge |

| 3 in. | 15.75 in. | 8 ft. | 16.8 | Square Edge |

| 3 in. | 16 in. | 8 ft. | 16.8 | Square Edge |

Note: Please be advised that additional sizes may be available. Availability of all sizes varies by region and is subject to change. For further information, please contact your local DuPont Sales Representative or call us at 1-866-338-7668.

Testing

<b>Styrofoam™ Brand Cavitymate™ Ultra XPS Insulation</b> exhibits physical properties as indicated in the table below when tested as represented. Review all instructions and (Material) Safety Data Sheet ((M)SDS) before use. Please contact DuPont at 1-833-338-7668 when additional guidance is required for writing specifications that include this product.

| TEST METHOD | TEST TITLE | PROPERTY | RESULTS |

|---|---|---|---|

| FIRE | |||

| UL 723 | Test Method for Surface Burning Characteristics of Building Materials | Surface Burning Characteristics | Flame Spread ≤ 25 Smoke Developed ≤ 450 |

| THERMAL | |||

| ASTM C518 | Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus | Thermal Resistance per inch, @ 75°F mean temp.1 | 5.6 ft2 •h•°F/Btu, R-value, min. |

| ASTM D696 | Standard Test Method for Coefficient of Linear Thermal Expansion of Plastics Between −30°C and + 30°C with a Vitreous Silica Dilatometer | Coefficient of Linear Thermal Expansion | 3.5 x 10-5 in/in•°F |

| ASTM D2126 | Standard Test Method for Response of Rigid Cellular Plastics to Thermal and Humid Aging | Change in Dimensions | 2.0 % change, max. |

| STRENGTH | |||

| ASTM D1621 | Standard Test Method for Compressive Properties of Rigid Cellular Plastics | Compressive Strength2 | 25 psi, min. |

| ASTM C203 | Standard Test Methods for Breaking Load and Flexural Properties of Block-Type Thermal Insulation | Flexural Strength | 50 psi, min. |

| WATER | |||

| ASTM C272 | Standard Test Method for Water Absorption of Core Materials for Sandwich Construction | Water Absorption | 0.1 % by volume, max. |

| ASTM E96 | Standard Test Methods for Gravimetric Determination of Water Vapor Transmission Rate of Materials | Water Vapor Permeance3 | 0.8 perm, max. |

1Values are consistent with the criteria of ASTM C578 and the requirements of the FTC R-value rule (16 CFR Part 460). R means resistance to heat flow. The higher the R-value, the greater the insulating power.

2Vertical compressive strength is measured at 10 percent deformation or at yield, whichever occurs first. Since Styrofoam™ Brand Extruded Polystyrene Foam Insulations are visco-elastic materials, adequate design safety factors should be used to prevent long-term creep and fatigue deformation.

3Based on 2.125” thickness.

Code Compliance

<b>Styrofoam™ Brand Cavitymate™ Ultra XPS Insulation</b> complies with the following codes:

| Code | Description |

|---|---|

| US Product Listings & Verifications | International Residential Code (IRC) and International Building Code (IBC); see ICC-ES ESR-4755<br>Underwriters Laboratories, Inc. (UL) Classified, see Classification Certificate D-369<br>DrJ TER 1303-01 |

| Regional Code Listings & Reports | California Std. Reg. #CA T1535 |

For more information on the Ultra Air Barrier Wall System see:

For more information on the Ultra Air Barrier Wall System see:

For more information on the Ultra Air Barrier Wall System see:

For more information on the Ultra Air Barrier Wall System see:

For more information on the Ultra Air Barrier Wall System see:

For more information on the Ultra Air Barrier Wall System see:

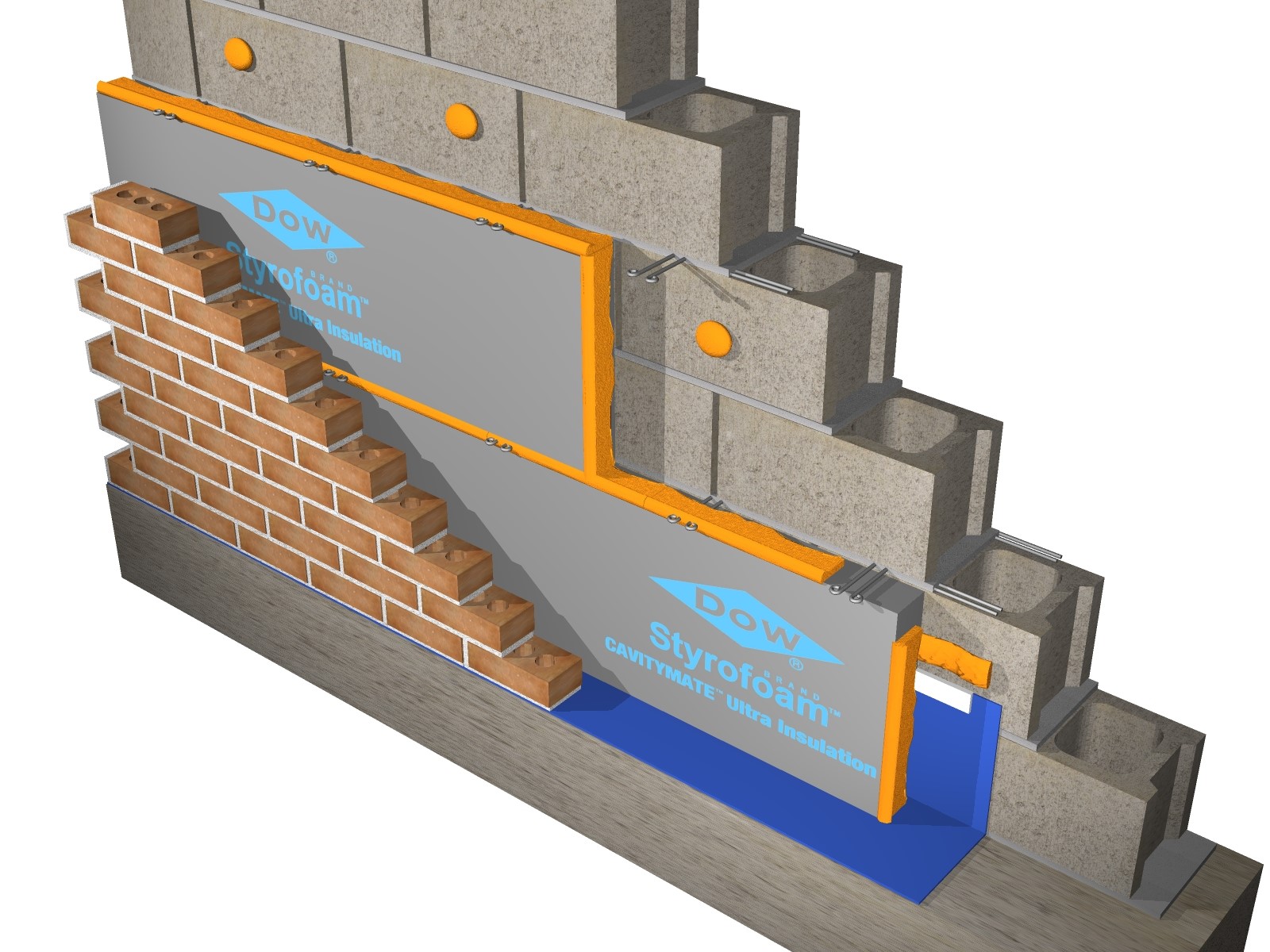

2) The 4'x8'DuPont™ Styrofoam™ Brand Ultra SL Extruded Polystyrene (XPS) Foam Insulation solution with joints sealed with DuPont™ LiquidArmor™ Flashing and Sealant.

2) The 4'x8'DuPont™ Styrofoam™ Brand Ultra SL Extruded Polystyrene (XPS) Foam Insulation solution with joints sealed with DuPont™ LiquidArmor™ Flashing and Sealant.

This isn't new, 16-inch wide products have been available for this application for decades. However, in the Ultra Air Barrier Wall System there needed to be a ¼ inch gap to hold the Great Stuff Pro™ single component foam that is applied after the boards are mounted to the wall. This foam sealant provides the air and water barrier properties for the assembly. This is why the insulation boards are only 15¾ inch wide.

This isn't new, 16-inch wide products have been available for this application for decades. However, in the Ultra Air Barrier Wall System there needed to be a ¼ inch gap to hold the Great Stuff Pro™ single component foam that is applied after the boards are mounted to the wall. This foam sealant provides the air and water barrier properties for the assembly. This is why the insulation boards are only 15¾ inch wide.

For more information on the Ultra Air Barrier Wall System see:

For more information on the Ultra Air Barrier Wall System see: