AGA fire study offers key learnings for fire hazards in your industry

ArticleThe American Gas Association (AGA) is a trade organization made up of 200 companies that service 95% of natural gas customers in the United States. The AGA completed an extensive study of workplace natural gas fires, providing data for safety managers and hazard assessments. The study was supported with collaboration between 14 natural gas and safety companies, including fire experts from DuPont, and focused on four main questions:

What is the escape time for a worker in different work environments wearing different types of PPE?

How long does it take a standby employee to extinguish an excavation fire?

How much heat is generated by a natural gas fire and what is the maximum exposure temperature?

What is the relative performance of different flame-resistant (FR) garment configurations at extended exposure times?

This article presents some key findings for each of these four questions.

Escape time

A worker simulating an excavation job assignment began either standing or kneeling on one knee at a pipe buried to either a 4 or 6 foot depth. Escape time was measured from the starting location to a point 10 feet away.

The average escape time across all conditions was 3.85 seconds and does not include normal human reaction time to perceive danger and react, which could add an additional 1.5 seconds.

Escape times varied by up to 45% based on the age, gender, body size and years of service of the employee.

Escape time was not affected by the weight or type of FR garments worn, but was negatively affected by restricted vision from a respirator.

Escape time was longer from workplace environments that included a ladder, but under duress not all participants used the ladder to escape.

Bystander firefighting

A bystander employee was timed from a starting location 10 feet from an excavation fire at depths of either 4 or 6 feet until the fire was put out. Study participants used a common dry powder extinguisher.

The average time to extinguish the fire was consistently between 5 and 6 seconds.

Fire extinguisher weight or powder type did not affect extinguishing time, but multiple strikes to puncture a new cartridge could add as much as an additional 10 seconds to put out the fire.

Heat flux

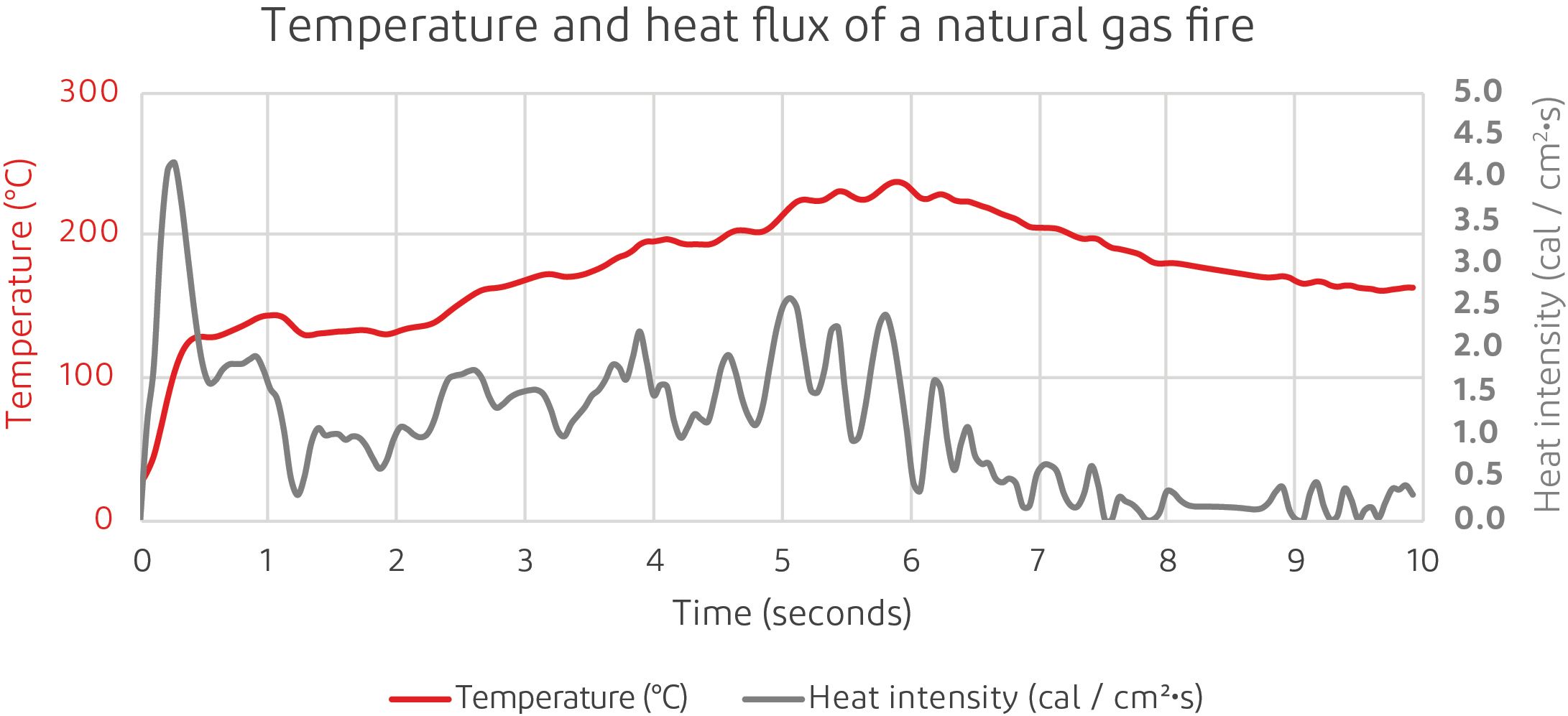

A first-of-its-kind system was designed using slow-motion infrared video imagery to measure the fire intensity that would occur in the locations of a worker or standby employee involved in a natural gas excavation fire.

The average heat flux was approximately 2 calories / (cm2•s) with the highest heat intensity observed 3 feet from the floor of the excavation.

The maximum temperature of exposure was on average 200°C (392°F).

PPE protection levels

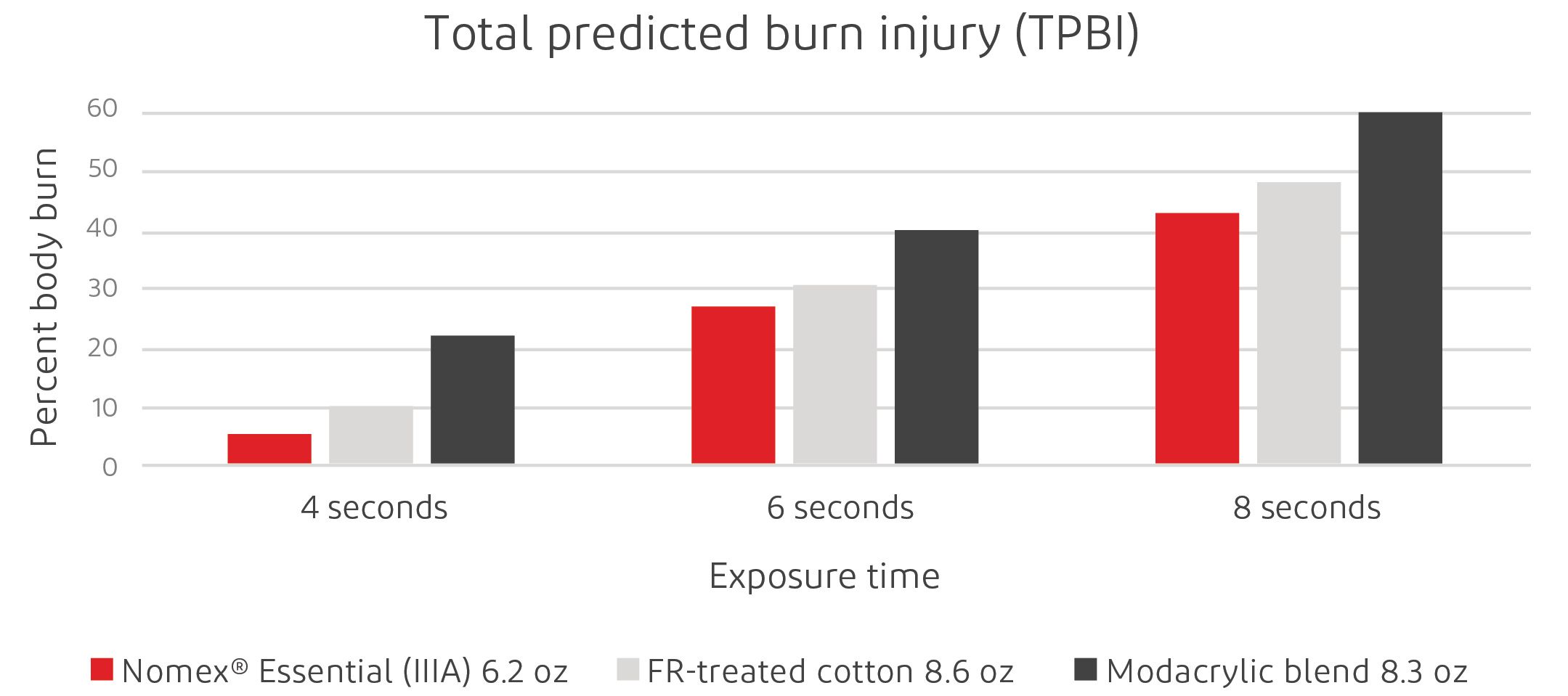

Outcomes of these three studies were used to compare the predicted body burn of different FR PPE multi-layer garment systems. Thermal manikin testing was conducted at a heat flux of 2 calories / (cm2•s) and exposure times of 4, 6 and 8 seconds. For the results below, the thermal manikin was dressed in cotton undergarments, cotton jeans and an FR coverall constructed of the fiber as noted. Total predicted body burn results do not include the head.

Garments made of Nomex® Essential (IIIA) generated lower predicted body burn at lower fabric weights for all exposure times compared with modacrylic blends or flame-retardant-treated cotton.

Garment weight alone is not a reliable predictor of FR garment protection.

Proper sizing and fit of FR garments is very important for protection. Wearing garments too tightly can increase predicted burn injury by up to 15%.

Conclusion

Although this study was conducted for the natural gas industry, the findings may be transferred to other work environments where a thermal or fire hazard exists.