Technical Information - Test Results for DuPont™ Tyvek®

Article | September 20, 2019Tyvek® is formed by a fully integrated process using continuous and very fine fibers of 100 percent high-density polyethylene that are randomly distributed and nondirectional. These fibers are first flash spun, then laid as a web on a moving bed before being bonded together by heat and pressure - without the use of binders, sizers or fillers. By varying both the lay-down speed and the bonding conditions, DuPont technicians can engineer the flashspun sheet to meet market needs, such as soft- and hard-structure Tyvek®.

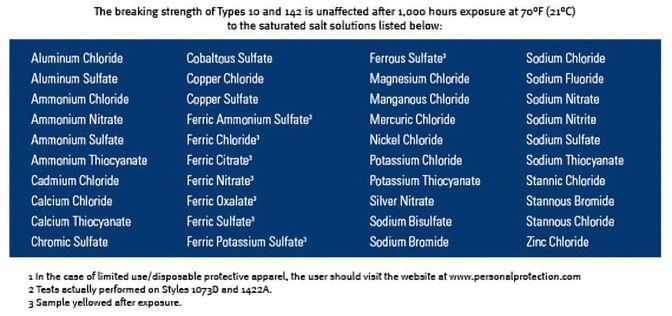

Table I - Resistance of DuPont™ Tyvek® to Salt Solutions1

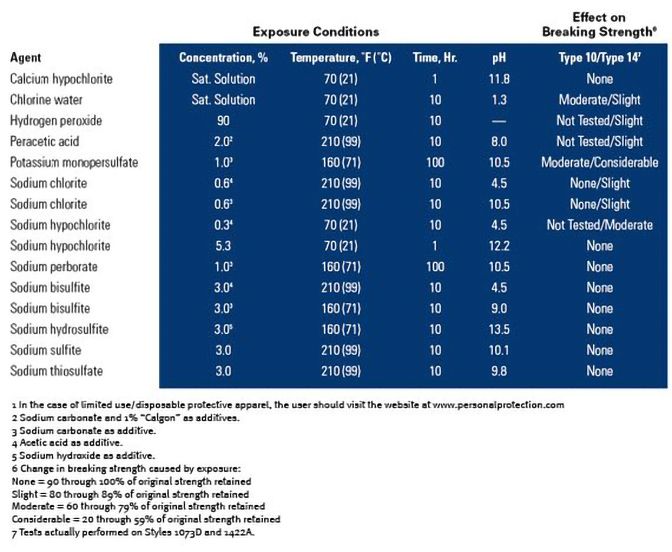

Table II - Resistance of DuPont™ Tyvek® to Oxidizing and Reducing Agents1

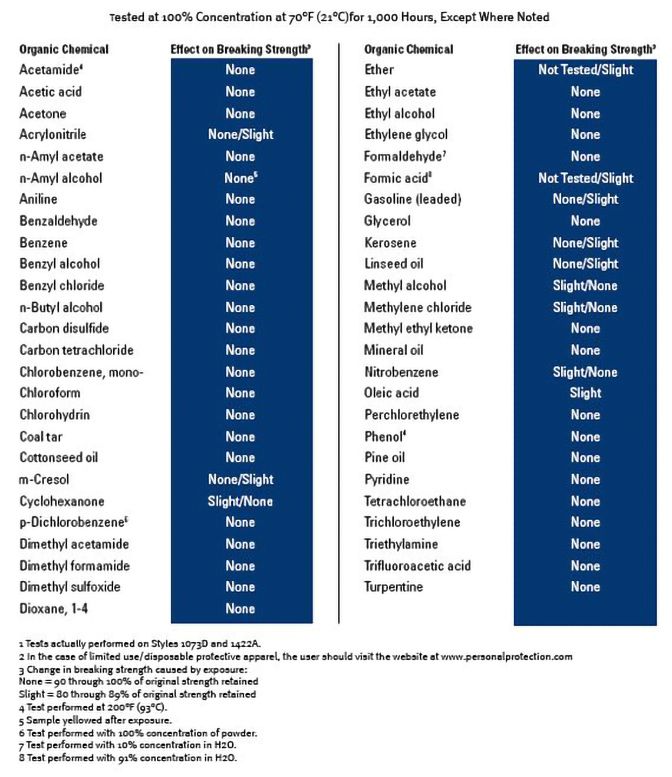

Table III - Resistance of DuPont™ Tyvek® to Organic Solvents2

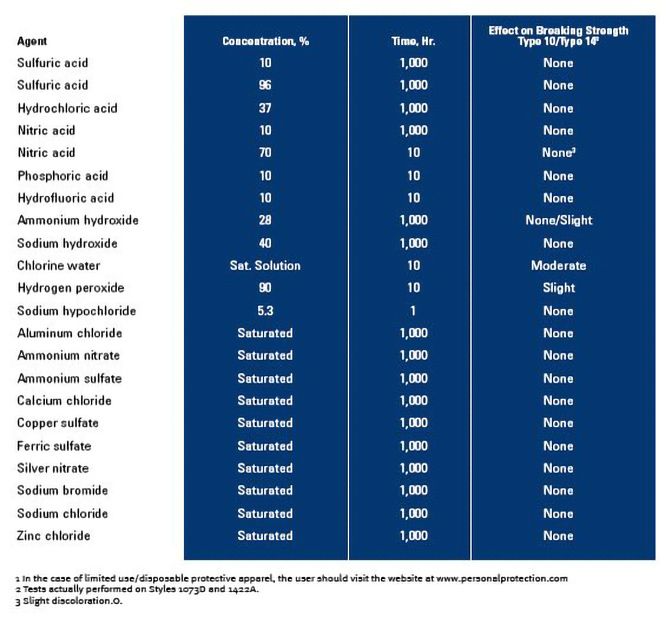

Table IV - Resistance of DuPont Tyvek® to Inorganic Chemicals at 70°F (21°C)1

Table V - Order of Increasing Swelling Effect of Solvents on DuPont™ Tyvek®1