A Classic Reborn: DuPont Solutions Play Key Role in All-New Electric London Black Taxis

Article | May 16, 2019

When London’s classic black taxis were transformed into range-extended electric vehicles, DuPont’s structural and glass bonding expertise played a critical role.

Designers at the London EV Company (LEVC) envisioned the TX5 model with a lightweight, extruded-aluminum body structure. To implement the innovative design of the six-passenger taxi and meet safety standards, they needed comprehensive bonding and adhesive solutions.

Challenges

Safety and durability:

All applications were required to meet international vehicle safety standards as well as OEM durability specifications.

Production:

Glass bonding applications needed to be compatible with the vehicle production process, including cold- and warm-applied systems.

Passenger comfort:

Sound and temperature must be managed to ensure passenger comfort.

Emissions:

Starting in 2018, all new licensed taxis in London had to be “zero emissions capable."

The Solution

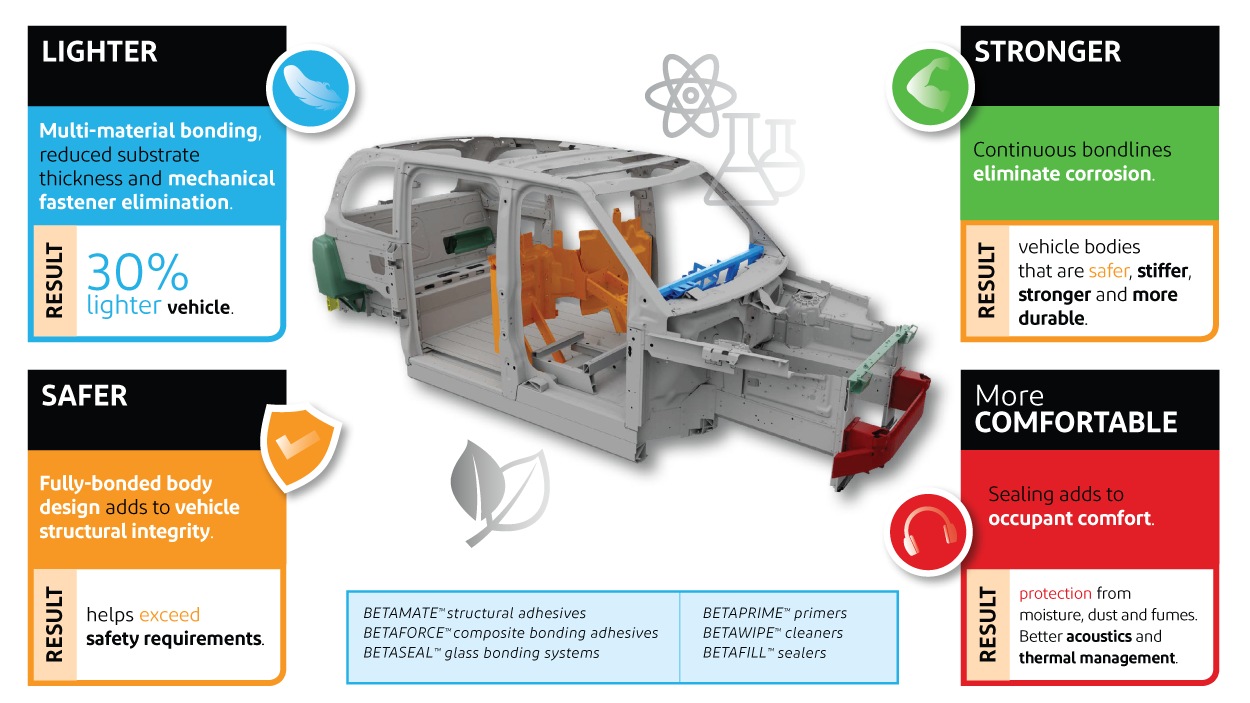

The results of the collaboration between DuPont and LEVC are impressive by any standard: a fully bonded body structure that is 30% lighter than an equivalent steel construction. This accomplishment entirely depended on the strength of the adhesive; there are no mechanical fasteners!

The results?

A fully-bonded body structure that is 30% lighter than an equivalent steel construction.

A combination of BETAMATE™ products were used to:

- Help reduce substrate thickness

- Reduce weight

- Eliminate the need for mechanical fasteners.

BETAFORCE™ composite bonding adhesives, BETASEAL™ glass bonding systems, BETAPRIME™ primers, BETAWIPE™ cleaners and BETAFILL™ sealers also were used to:

- Integrate all parts of the TX5’s lightweight bonded extruded aluminum monocoque body-in-white. Through bonding, the chassis, brackets, posts, roof, and fixed glass became a structural unit.

- Bond the car body as well as SMC body panels and door skins

- Fill gaps and finish seams while helping prevent moisture intrusion that can lead to corrosion and providing acoustical and thermal management benefits.

DuPont solutions for electric TX5 London Black Taxi

Fully-bonded body structure that can be up to 10X stronger than steel* on an equal weight basis and 30% lighter than equivalent steel construction

DuPont’s high-performance solutions contributed to achieving a fully-bonded body structure that can be up to 10X stronger than steel* on an equal weight basis and significantly lighter than an equivalent steel construction. In addition to increased safety for the occupants, the weight savings also contribute to greater efficiency when in electric mode.

When the TX5 hit the streets of London, passengers enjoyed riding in comfort with seating for six, forward-facing wheelchair access, power sockets for laptops, USB ports, on-board Wi-Fi, a panoramic roof and active and passive safety systems standard. The TX5 can travel up to 80 miles on a single battery charge and is fitted with 1.5 liter gas engine to assist with long journeys.

DuPont is already working with LEVC on the next generation of electric London Black Taxis. In addition, vehicles have also been deployed in Oslo, Hamburg and Berlin. LEVC has announced that the TX5 all-electric black taxi will begin transporting passengers in Paris in 2019.

Why Choose BETAMATE™?

BETAMATE™ structural adhesives deliver cutting-edge solutions in similar and dissimilar material bonding, closure bonding, and body structure bonding, enabling improved load carrying capabilities, vehicle stiffness and durability, design flexibility, and weight reduction. BETAMATE™ structural adhesives offer high-performance adhesion to automotive substrates such as steel, aluminum, magnesium, and composites, innovatively replacing welds and mechanical fasteners, reducing fatigue and failure commonly encountered with traditional processes – substantially increasing manufacturing efficiencies.

BETAMATE™ Benefits

- Contributes to lightweight design flexibility and safety

- Joins multi-material and hard-to-weld substrates, including high-strength steel, aluminum and magnesium

- Improves durability by reducing fatigue and failure commonly found around spot welds and fasteners

- Seals against environmental conditions that cause corrosion

- Provides potential to lower cost by reducing welds and gauge without losing mechanical properties

- Lab and full-vehicle testing of new crash-resistant structural adhesives show improved crash-resistant performance without any weight increase

*Results may vary as there are multiple types of steel with varying tensile strengths and multiple types of Kevlar® yarn with varying tensile strengths.