At our core: the historical origins of safety at DuPont

Article | May, 22 2019

Today DuPont is known for a wide array of products— additives and modifiers for polymers, electronic technologies, construction materials, and many more. But in 1802, when E.I. du Pont founded the company on the shores of the Brandywine Creek, he had a single product in mind: gunpowder.

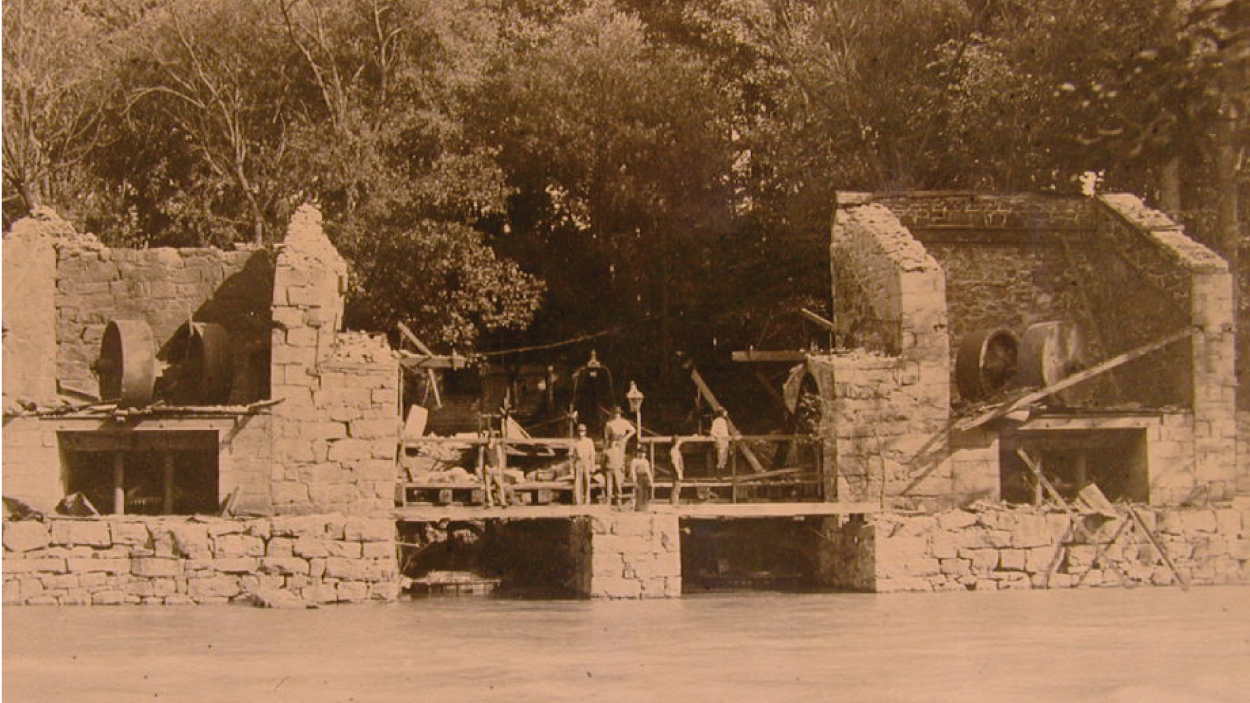

Unlike typical leaders of business and industry of the era, E.I. du Pont cared deeply about safety. The buildings in which the gunpowder was manufactured featured strong granite walls on three sides. The fourth side, open or built of light wood, faced the Brandywine, ensuring that the force of any accidental explosion would be directed out over the water where it would do the least damage. Determined that he and his family would share any risk with employees, he built his house right there in the blast zone.

In 1811 came the company’s first written safety rules. No strangers allowed in the powder yards. No matches or tobacco. No alcohol on company property. Immediate dismissal of anyone who showed up for work intoxicated. No sharp metal objects such as pocket knives that could cause sparks. No kind of play or “disorderly fun.” Zero tolerance. Clearly, safety was serious business.

Nevertheless, there were setbacks. Explosions in 1815 and 1818 killed 45 and injured many more. The company adopted a policy that provided free housing and lifetime pensions to widows and dependents of deceased workers—something virtually unheard of in American industry at the time.

Safety practices at DuPont evolved with the company. In the mid-1800s Lammot du Pont developed machinery designed to mechanize processes formerly done by hand, thus shielding employees from danger. As the company made its transformation into chemical processing, safety policies and procedures evolved accordingly, becoming more complex and precise.

In the early 1900s the company organized a formal safety program designed to prevent accidents of all kinds. And it hired its first full-time physician, one of only a few companies to do so. To this day, DuPont employs a chief medical officer and several physicians around the world dedicated to the health and safety of employees.

By the 1920s, safety claimed the same status as other operational priorities: such as quality, productivity, and profitability.

In 1911, DuPont launched a major “Safety First” program by organizing workers’ safety committees, publishing safety literature, and sponsoring rallies at plants to promote safety awareness and injury prevention. This led to our being recognized widely as source of safety information, resources, and practices for companies all around the world.

In 1912, with the creation of the U.S. National Safety Council, the industry began keeping safety records. DuPont went from a frequency rate of 43.2 (major injuries per million hours worked) in 1912 to just 3.40 in 1927, the company’s 125th anniversary, reflecting that safety claimed the same status as other operational priorities such as quality, productivity, and profitability.

Yes, a lot has changed in the more than two centuries since our founding. But our legacy of safety and health lives on. And as our company transforms to meet the needs of a growing population, it will continue to be a core value at DuPont.